Cold rolling yarn stacking and dyeing device

A cold pad-batch dyeing and equipment technology, applied in lighting and heating equipment, liquid/gas/steam yarn/filament treatment, drying, etc., can solve the problems of heavy pollution, large equipment investment, high energy consumption, etc., and achieve equipment The effect of low investment, increased output, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

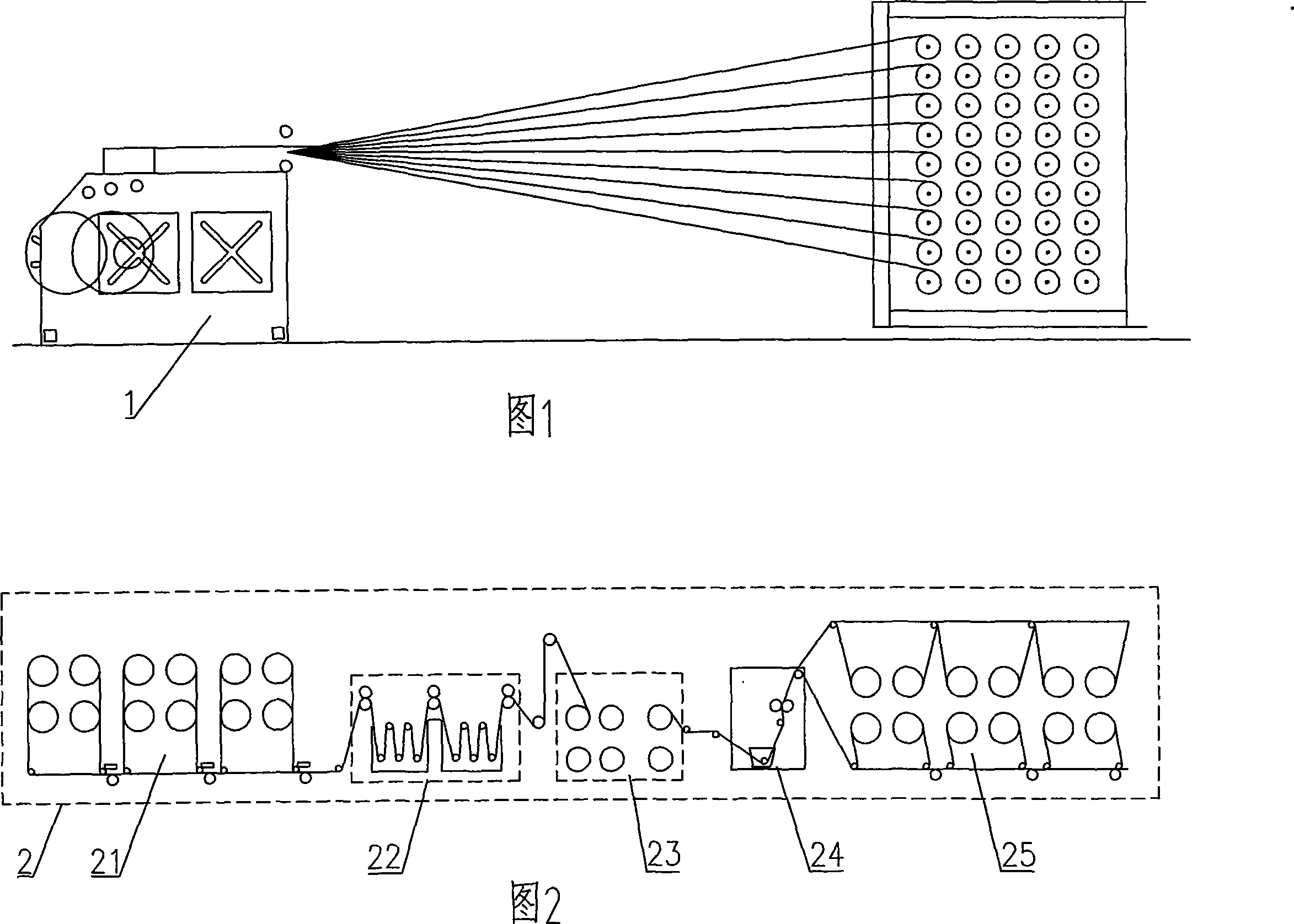

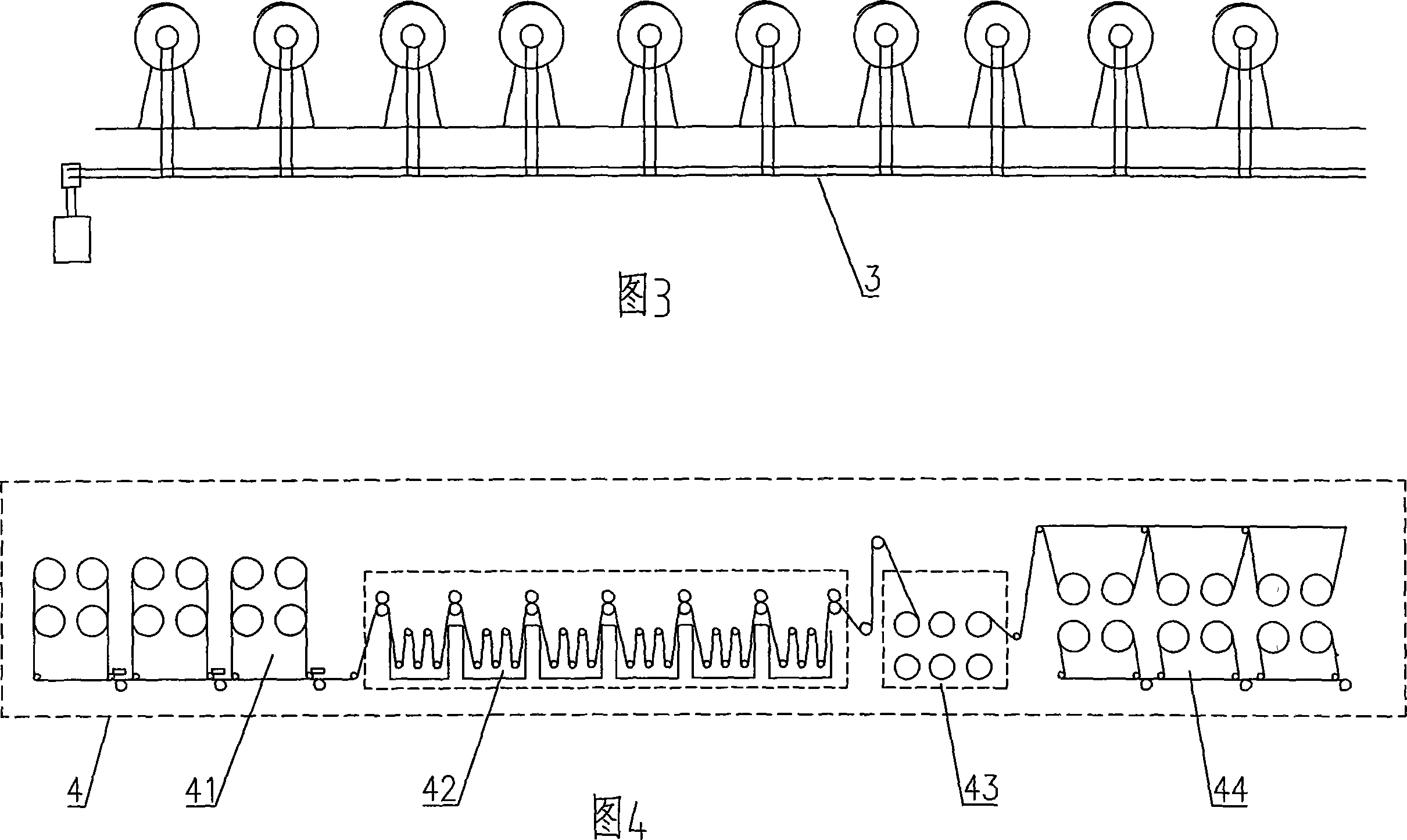

[0016] A kind of cold pad dyeing equipment as shown in Figure 1, 2, 3, 4, comprises high-speed warp car 1, padding cold rolling unit 2, cold dyeing device 3 and soaping drying unit 4, described padding The pad dyeing unit 2 is composed of a first yarn feeding device 21, a yarn padding machine 22, a first drying device 23, a pad dyeing device 24 and a first yarn receiving device 25, and the soaping and drying unit 4 is composed of The second yarn feeding device 41, the soaping dryer 42, the second drying device 43 and the second yarn receiving device 44 are arranged in sequence.

[0017] Pad dyeing device 24 is the key point of this equipment: the ratio of dye liquor and lye is evenly added to the pad dyeing tank, and the dyeing tank must be controlled between 20-40 liters of dye liquor to ensure a fast dye liquor replacement speed, so that Replace the dye solution once within 20 minutes, thus solving the problem of head-to-tail color difference; uniform pressure of the pad dye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com