Method for sealing circumference of vacuum glass

A vacuum glass and glass technology, applied in glass forming, glass remolding, glass manufacturing equipment, etc., can solve problems such as troublesome use and difficult placement of seals, and achieve improved strength, improved air tightness, and solder edge. neat and beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

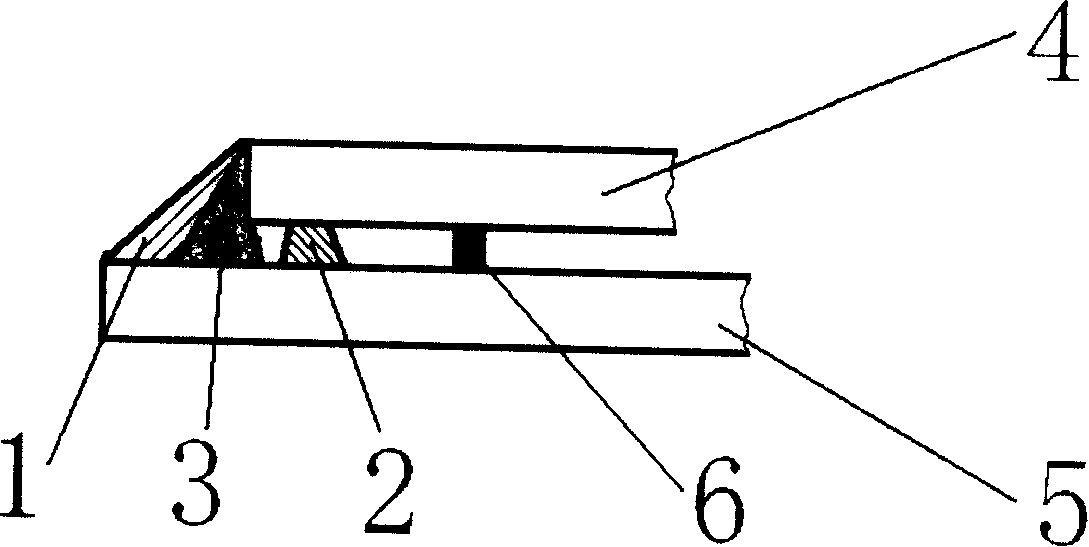

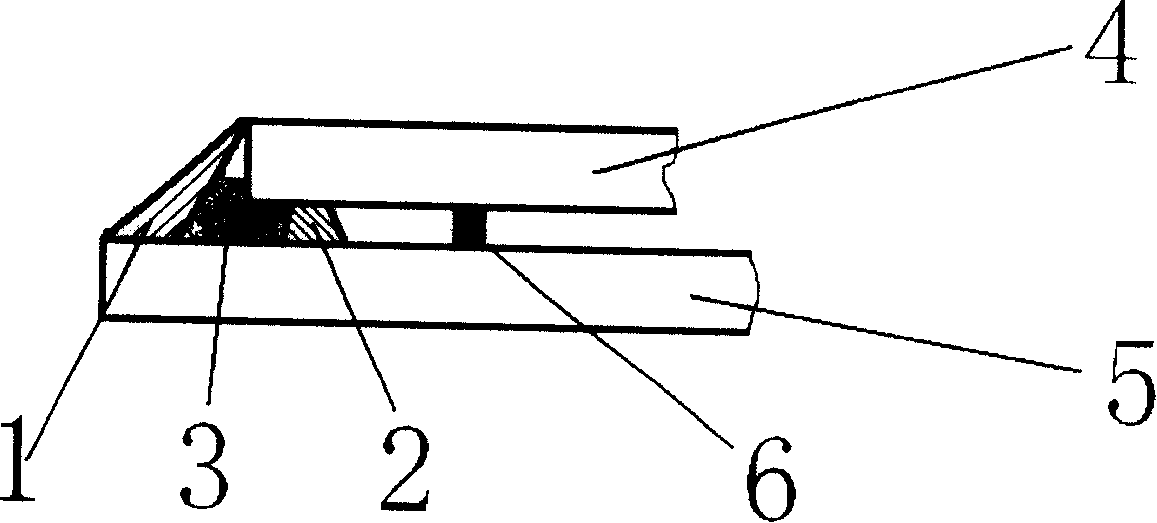

[0014] Such as figure 1 As shown, the inner anti-seepage layer is placed first, and the inner anti-seepage layer is made of aluminum oxide and water glass mixed with appropriate water in a ratio of 2:1. Next place the glass solder. Finally, the outer anti-seepage layer is applied, and the outer anti-seepage layer is formed by mixing aluminum oxide powder and water glass in a ratio of 2:1. Such as figure 2 As shown, the glass solder is condensed into a solid after being heated and melted, and the volume becomes smaller, and part of the molten glass solder penetrates into the gap between the upper and lower layers of glass. The outer barrier can be easily removed. The anti-seepage layer can also be made of titanium dioxide, glass powder and other inorganic powdery materials, which will not be listed here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com