Filling structure for fluid exchange column

A technology of fluid exchange and volume, applied in chemical/physical/physical-chemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of reduced processing efficiency and loss of fluid flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

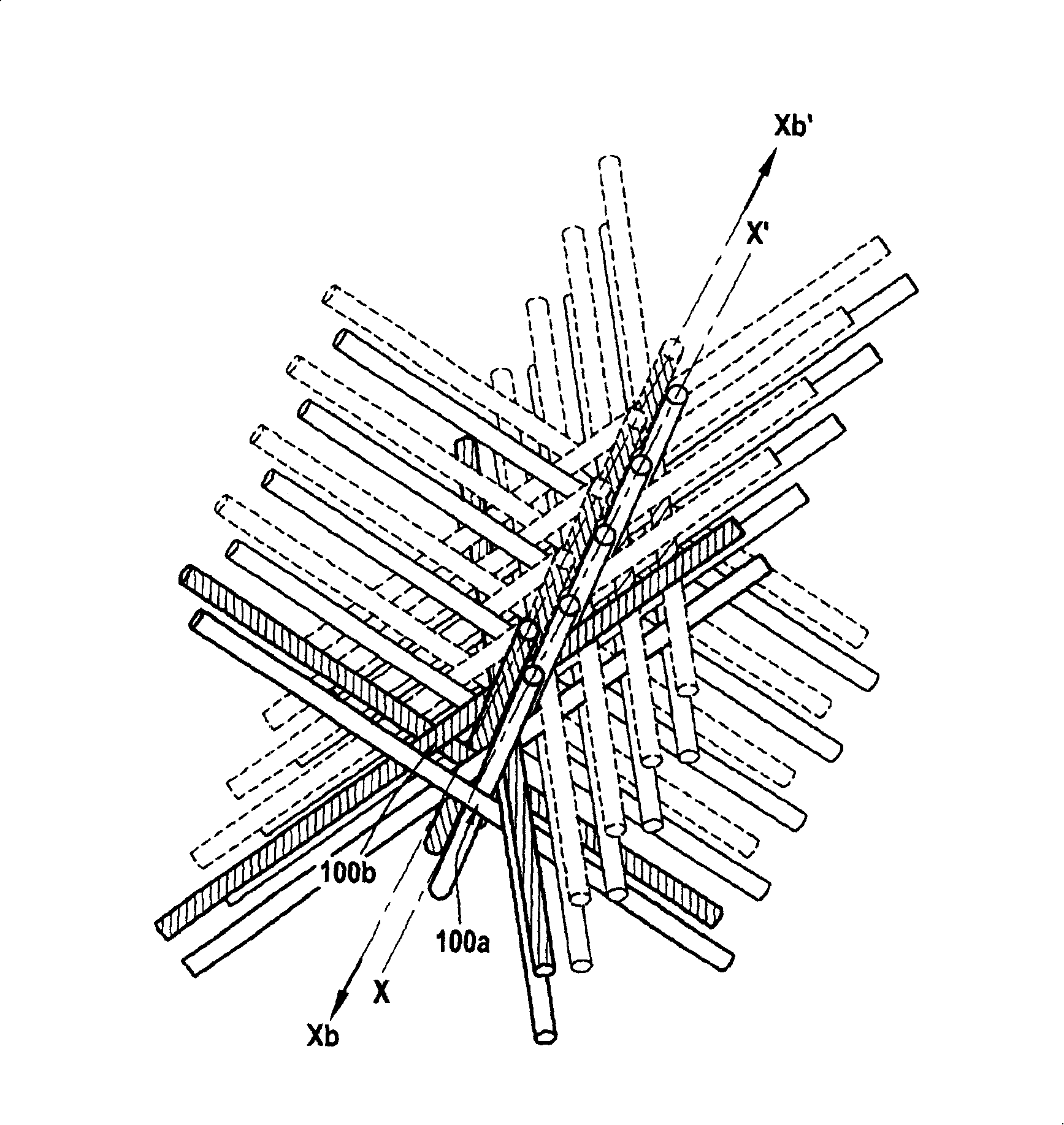

[0028] This description is referenced from Figure 1-4 The described method of manufacturing a filling structure according to an embodiment of the invention begins.

[0029] The structure consists of hollow tube assemblies. Therefore, the first step (step S1 ) is to form a hollow tube. The tube may be made of composite material such as carbon or ceramic (SiC), or indeed of metal, thermoplastic or thermosetting material. The tube preferably has the thinnest possible wall thickness in order to optimize the hollow part of the structure.

[0030] In the case of tubes made of composite materials such as carbon or SiC tubes, the tube can be formed, for example, from braids, filament windings, tapes, or from And tube formation consolidated by liquid techniques, ie by impregnating the braid with a resin such as phenolic resin that can be cokefied and infiltrated and cross-linking the resin by heat treatment.

[0031] The tube is preferably made of carbon / carbon composite material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com