InAlGaN/GaN PIN photoelectric detector without strain

A photodetector, strain-free technology, applied in the field of photodetectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

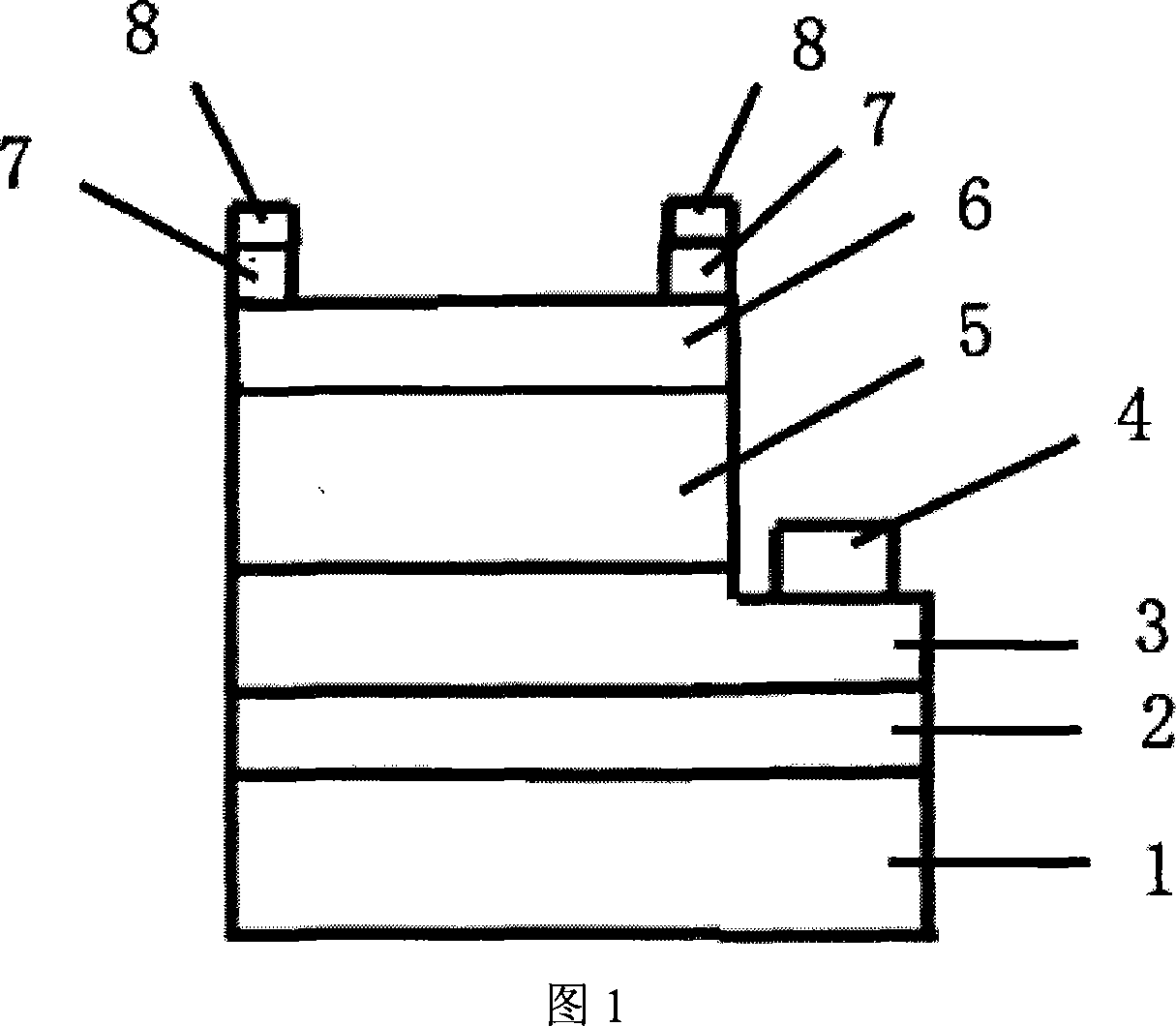

[0014] Referring to Fig. 1, the present invention is provided with sapphire (Al 2 o 3 ) substrate 1, GaN buffer layer 2, n-GaN layer 3, i-InAlGaN photosensitive layer 5, p-InAlGaN layer 6 and p-GaN top layer 7, from bottom to top GaN buffer layer 2, n-GaN layer 3, i -InAlGaN photosensitive layer 5, p-InAlN layer 6 and p-GaN top layer 7 are arranged on sapphire (Al 2 o 3 ) on the substrate 1, a p-electrode 8 is provided on the p-GaN top layer 7, and an n-electrode 4 is provided on the n-GaN layer 3.

[0015] The thickness of the GaN buffer layer 2 is 1-3 μm, the thickness of the n-GaN layer 3 is 1-3 μm, the thickness of the i-InAlGaN photosensitive layer 5 is 100-400 nm, the thickness of the p-InAlN layer 6 is 50-400 nm, and the p- The GaN top layer 7 has a thickness of 5-50 nm.

[0016] The p electrode 8 adopts a Ni / Au metal electrode, and the thickness of the Ni / Au metal electrode is (5-20) nm / (5-20) nm; the n-electrode 4 adopts a Cr / Al / Au metal electrode, and the Cr / Al / A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com