Eccentric ball iron pipe nodularity and wall thickness supersonic damage-free detection method

A technology of centrifugal ball and spheroidization rate, which is applied in the direction of using ultrasonic/sonic wave/infrasonic wave, using sound wave/ultrasonic wave/infrasonic wave to analyze solids, measuring devices, etc. Problems such as the difficulty of ultrasonic non-destructive testing of tube wall thickness, etc., to achieve the effect of improving accuracy and reliability, and improving coverage and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

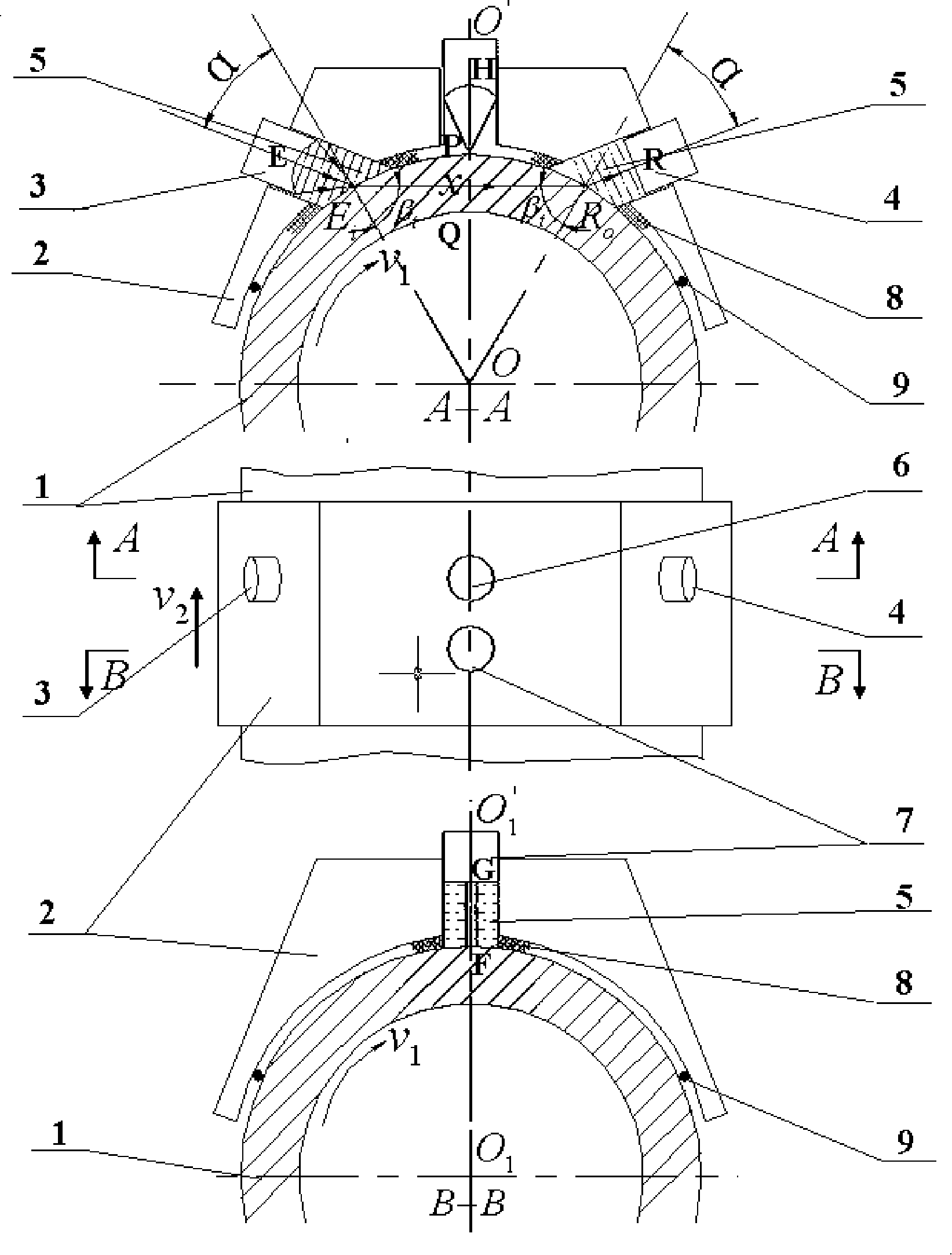

[0037] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solution and the drawings.

[0038] The position to be inspected on the surface of the inspected centrifugal ductile iron pipe 1 is defined as a plane A-A perpendicular to the central axis of the pipe 1 and intersecting the axis at point O. The intersection line of the plane and the pipe is a concentric ring centered on O. The outer diameter D is the outer diameter of the tube, the inner diameter d is the inner diameter of the tube, S=(D-d) / 2 is the wall thickness of the tube, and the ultrasonic transmitting probe 3 is a line focusing water immersion probe. then

[0039] Focal length in coupling medium

[0040] Focal belt width d -6dB =0.71λf / R c

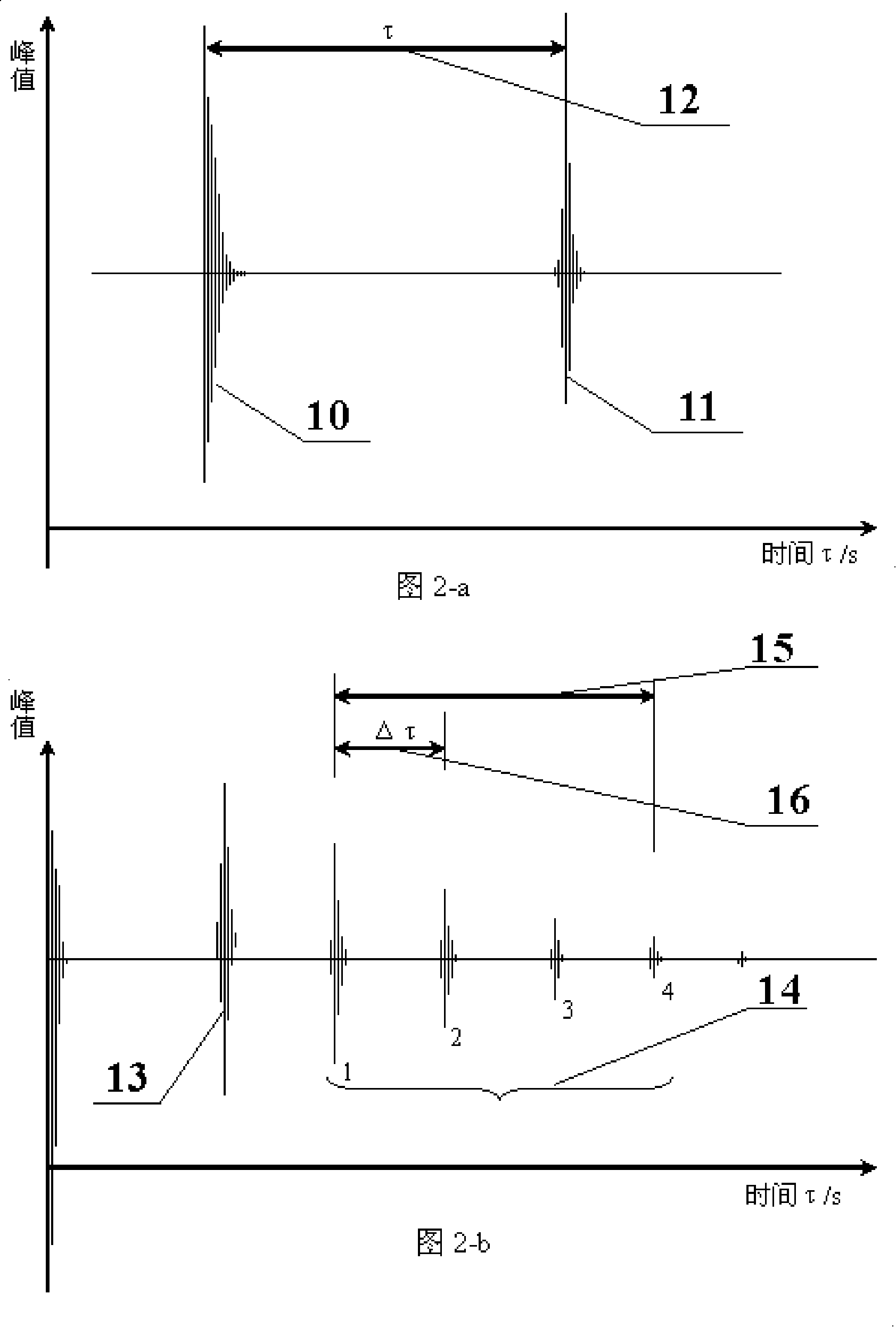

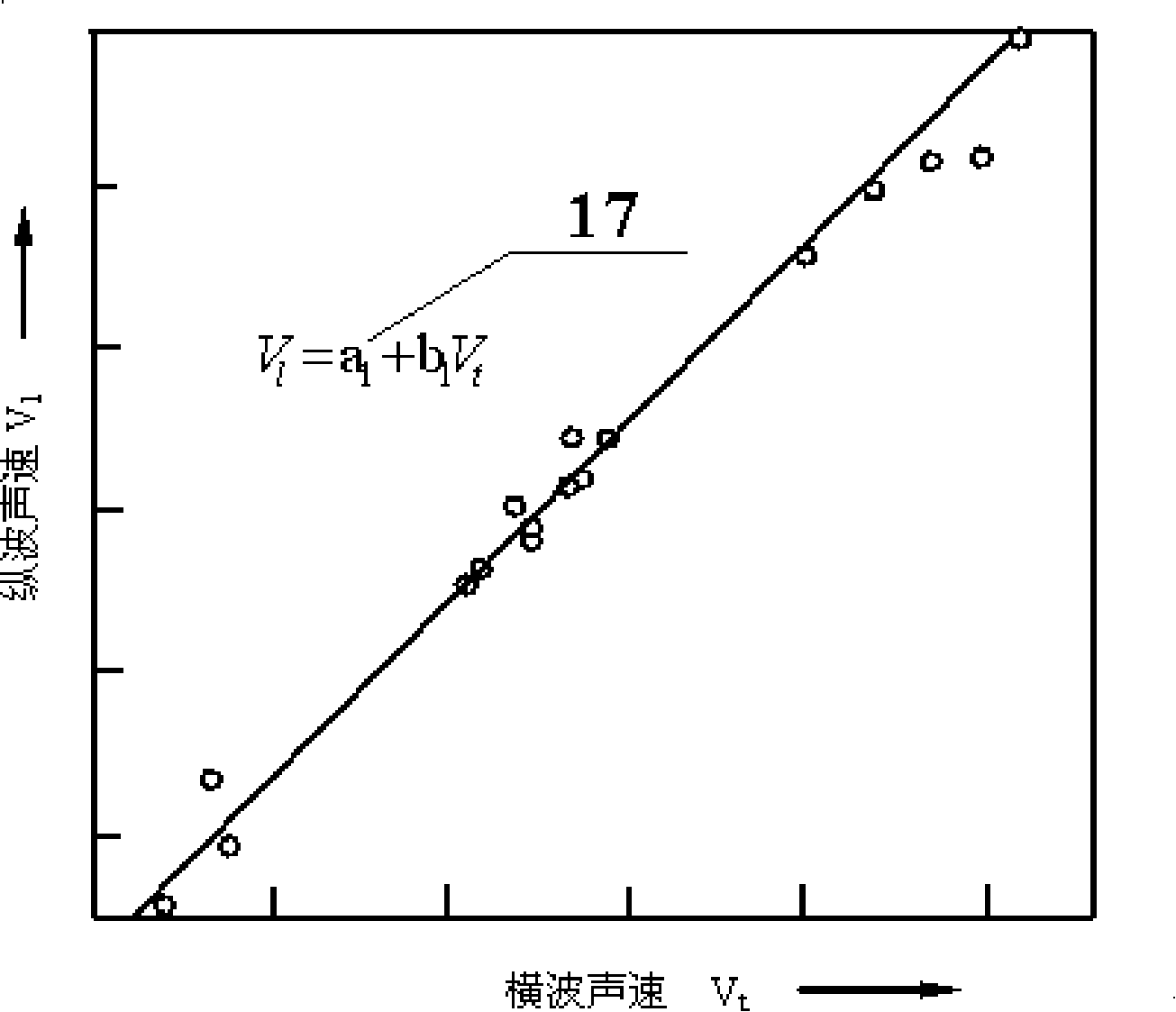

[0041] Where r is the radius of curvature of the probe focusing lens, C l The speed of longitudinal waves in the focusing lens, Acoustic velocity of longitudinal wave in coupling medium 5, wavelength in λ coupl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com