Large-scale precision bearing axial clearance multifunctional automatic measuring instrument

A technology of precision bearing and axial clearance, applied in the field of multi-function automatic measuring instruments, can solve the problems of human subjective error, troublesome operation, easy to produce errors, etc., achieve fast switching, easy operation, improve accuracy and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

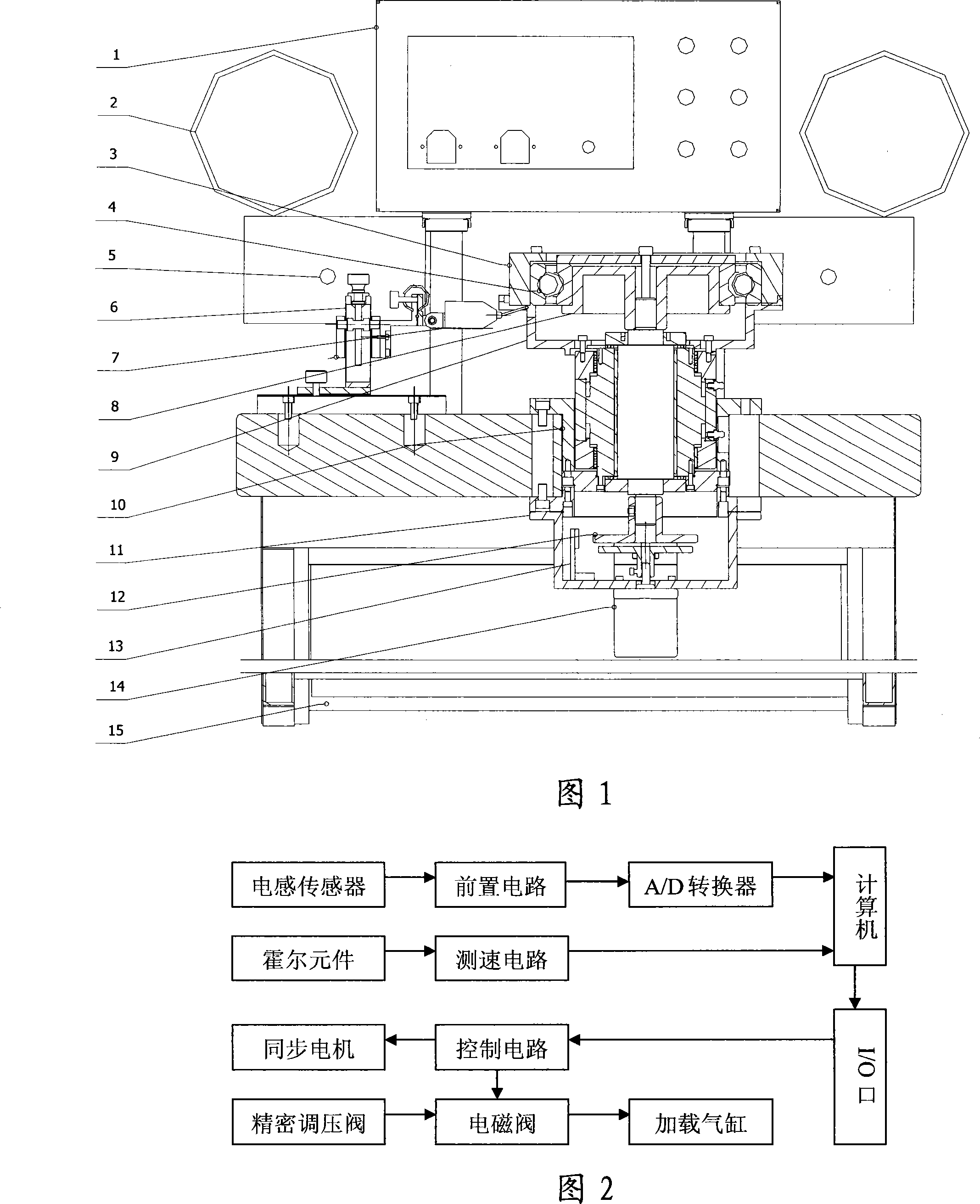

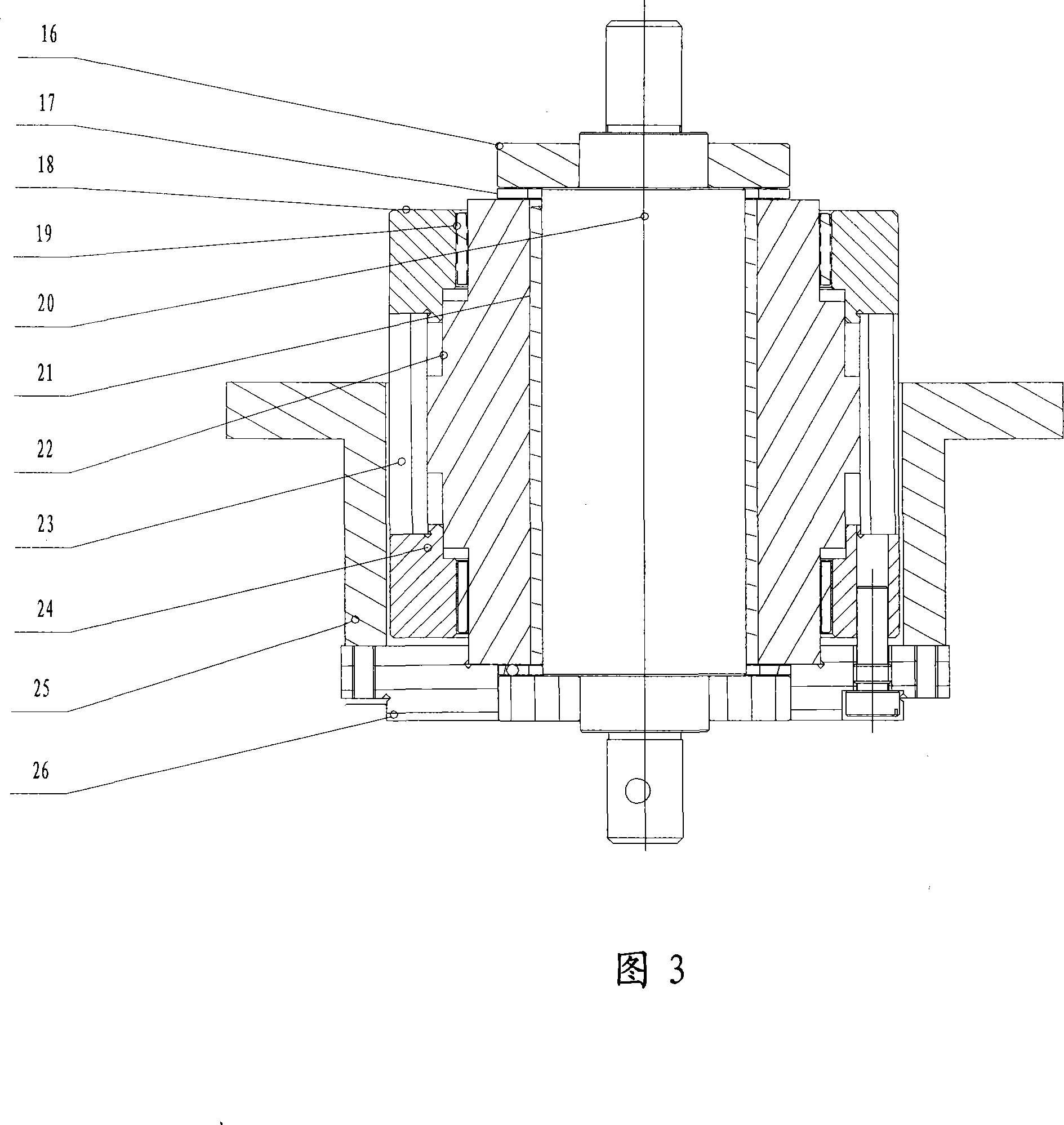

[0034]As shown in Figure 1: the synchronous motor (14) of the present invention drives the rotation of the measuring spindle and the loading cylinder device (10) through the fork coupling (12), and then drives the rotation of the measuring mandrel (8), and the measured bearing (4 )'s inner ring rotates at the same speed. The upper pressure sleeve (3) and the lower pressure sleeve (9) are rigidly connected with the outer ring of the tested bearing (4), and there is a certain axial clearance with the outer ring of the tested bearing (4) to facilitate axial To measure the clearance, the computer controls the measuring spindle and the upper cylinder liner (18) in the loading device (10) to move up and down through the solenoid valve to provide upper and lower loads for the tested bearing (4); move and adjust the sensor adjustment frame (6) , the lateral inductance sensor (7) measuring head acts on the center of the lower end face of the outer ring of the tested bearing (4), observ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com