Transparent heat insulating dope and preparation method thereof

A heat-insulating coating, transparent technology, applied in fire-resistant coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problem of processing metal-coated heat-reflecting glass and heat-reflecting film with high, low visible light transmittance, high process conditions, etc. Problems, to achieve the effect of simple and easy preparation and construction process, transparent and uniform appearance of the coating film, and high visible light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

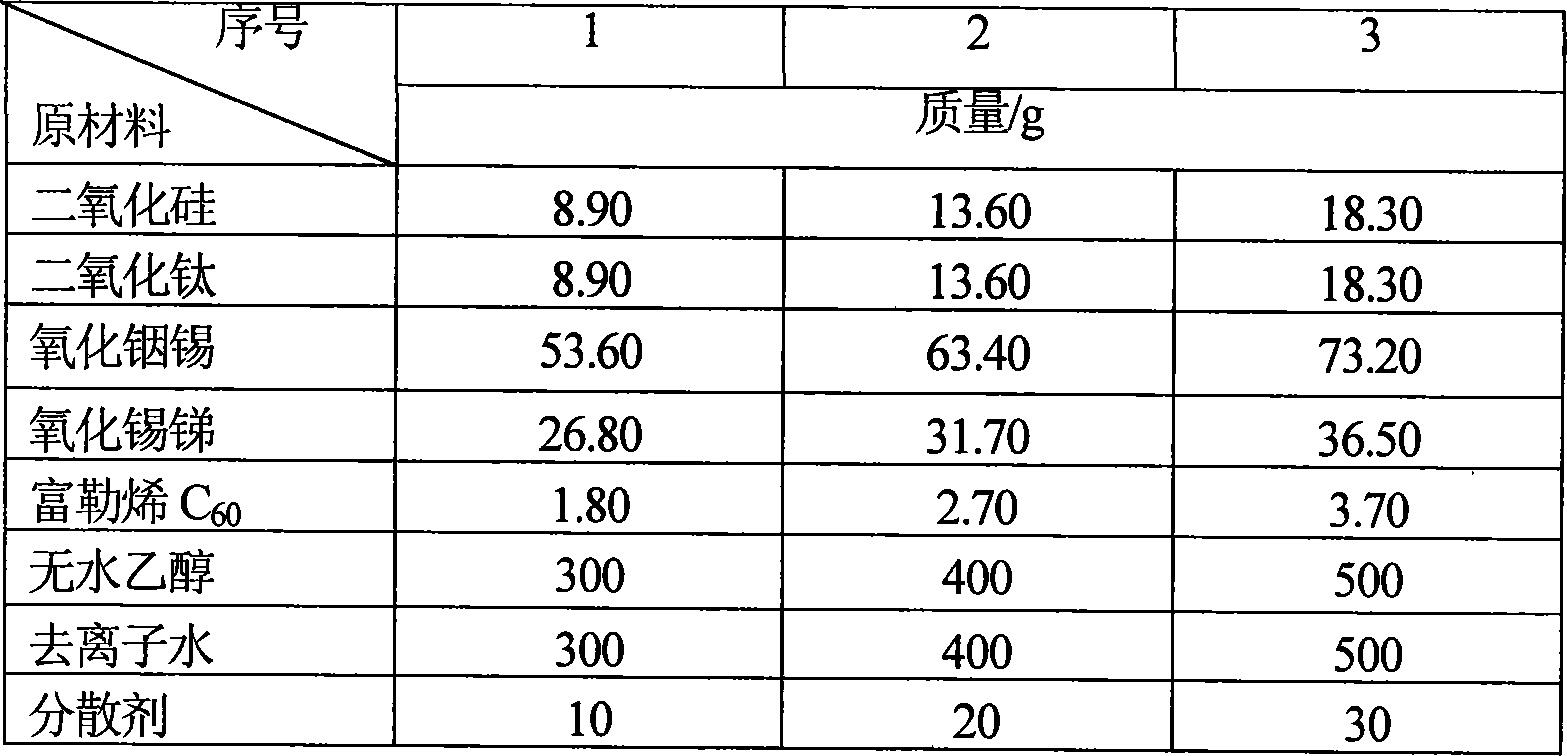

[0047] Embodiment 1: In a new high-grade office building, the product of the present invention is used to coat the glass on the exterior wall. The formula (total weight in 100 kg) is: 40 kg of aqueous polyurethane dispersion (solid content 30%), nano powder slurry (serial number 1 formula, adjusting pH to 6.5, homogenizing on a high-speed homogenizer for 30 min, using Ultrasonic dispersion 20 times) 15 kg, TD-441 0.02 kg, DF-5680.04 kg, ethylene glycol monobutyl ether 0.1 kg, water 44.84 kg, adjust the pH value to 6.5, and stir for 20 minutes to obtain a transparent heat-insulating coating. Before construction, use special cleaners and tools to thoroughly clean the window glass, pour the mixed main paint of heat insulation paint into the coating tank, use a special applicator to evenly dip the heat insulation paint in the tank, and apply it evenly on the existing Treated glass surface. The coating is a one-component room temperature curing type, which is surface dry in 1 hour...

Embodiment 2

[0048] Embodiment 2: In a new villa area, in order to improve the heat insulation effect, the product of the present invention is used to coat the outer wall with glass. The formula (total weight in 100 kg) is: 45 kg of aqueous PU dispersion (solid content 32.5%), nano powder dispersion slurry (No. , using ultrasonic dispersion 25 times) 20 kg, TD-4410.04 kg, DF-568 0.06 kg, ethylene glycol monobutyl ether 0.3 kg, water 34.6 kg, adjust the pH value to 7, and stir for 25 minutes to obtain a transparent heat-insulating coating. Before construction, use special cleaners and tools to thoroughly clean the window glass, pour the mixed main paint of heat insulation paint into the coating tank, use a special applicator to evenly dip the heat insulation paint in the tank, and apply it evenly on the existing Treated glass surface. The coating is a one-component room temperature curing type, which is surface dry in 1 hour and hard dry in 8 hours. For coated glass, do not scrub for two ...

Embodiment 3

[0049]Embodiment 3: In a shopping mall, in order to improve the heat insulation and light transmission effect of the shopping mall, the product of the present invention is used to coat the glass for the outer wall. The formula (total weight in 100 kg) is: 50 kg of aqueous PU dispersion (solid content 35%), nano-powder dispersion slurry (serial number 3 formula, adjust the pH value to 7.5, after homogenizing on a high-speed homogenizer for 60 minutes) , using ultrasonic dispersion 30 times) 25 kg, TD-441 0.06 kg, DF-568 0.08 kg, dipropylene glycol butyl ether 0.5 kg, water 24.36 kg, adjust the pH value to 7.5, and stir for 30 minutes to obtain a transparent heat-insulating coating. Before construction, use special cleaners and tools to thoroughly clean the window glass, pour the mixed main paint of heat insulation paint into the coating tank, use a special applicator to evenly dip the heat insulation paint in the tank, and apply it evenly on the existing Treated glass surface. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com