Electrohydraulic excitation controlling valve

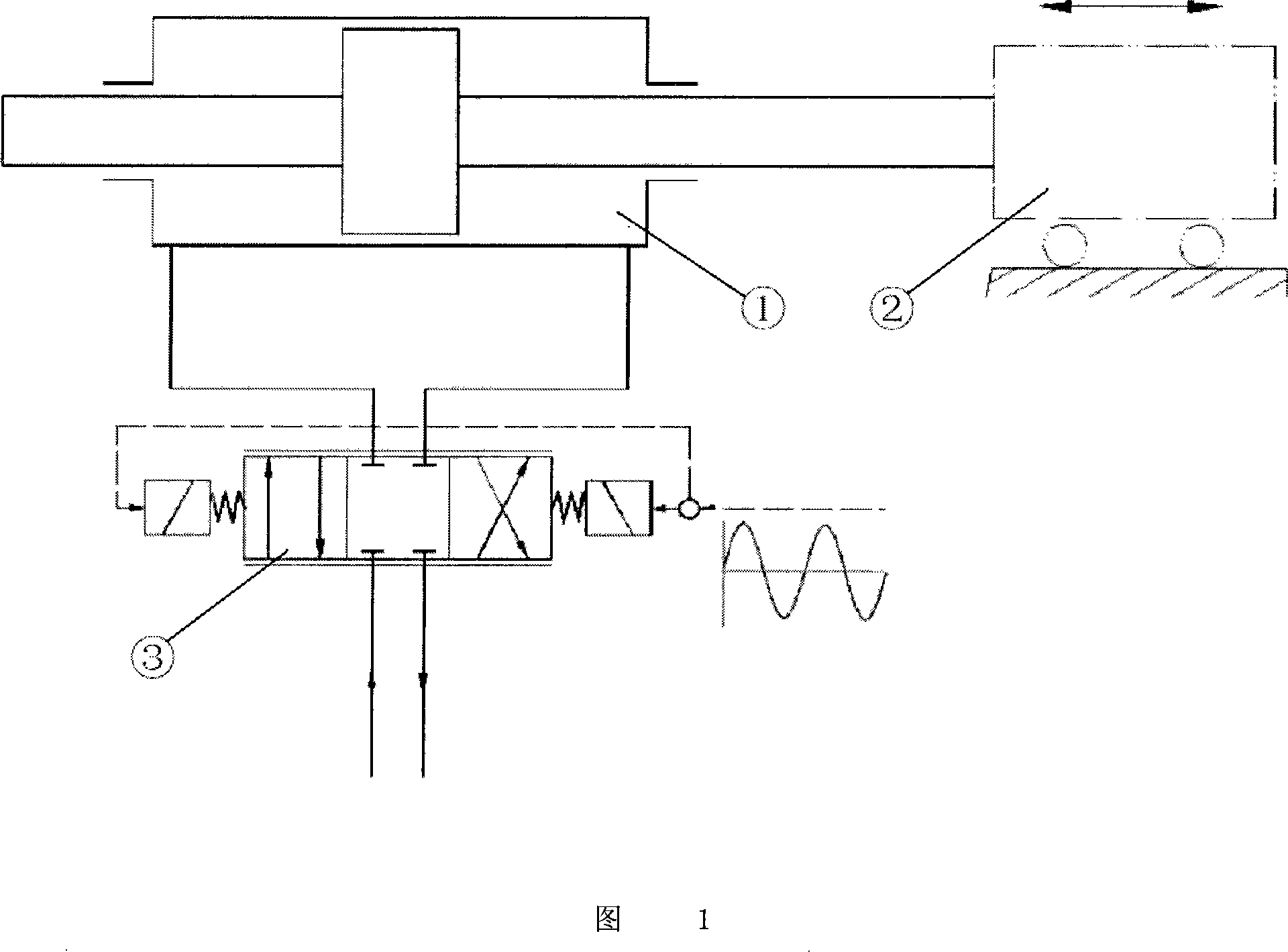

An electro-hydraulic vibration excitation and valve control technology, which is applied in vibration testing, measuring devices, fluid pressure actuating devices, etc., can solve the problem that the working frequency of the electro-hydraulic servo vibration table is difficult to be further increased, and achieve the effect of increasing the excitation frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

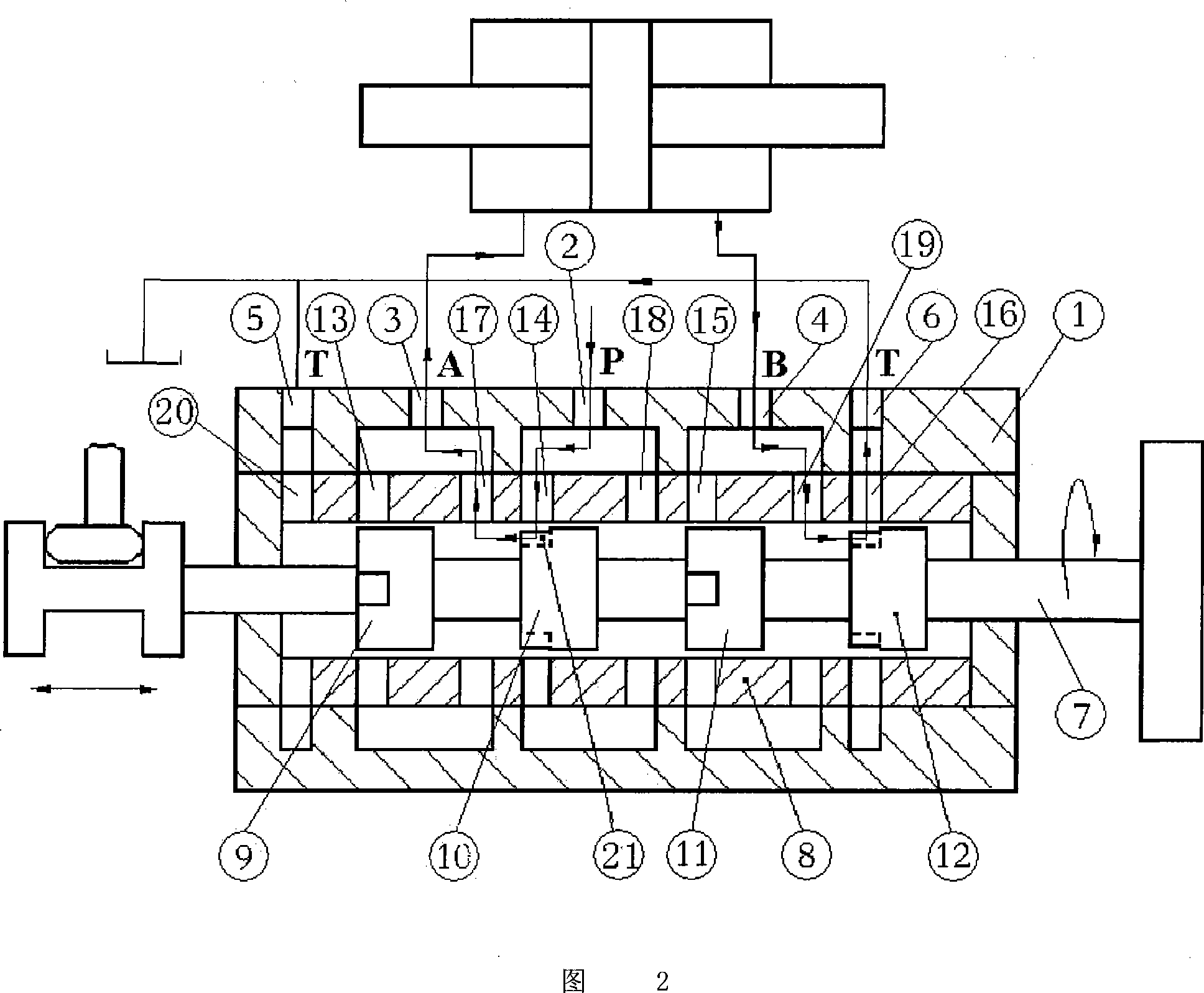

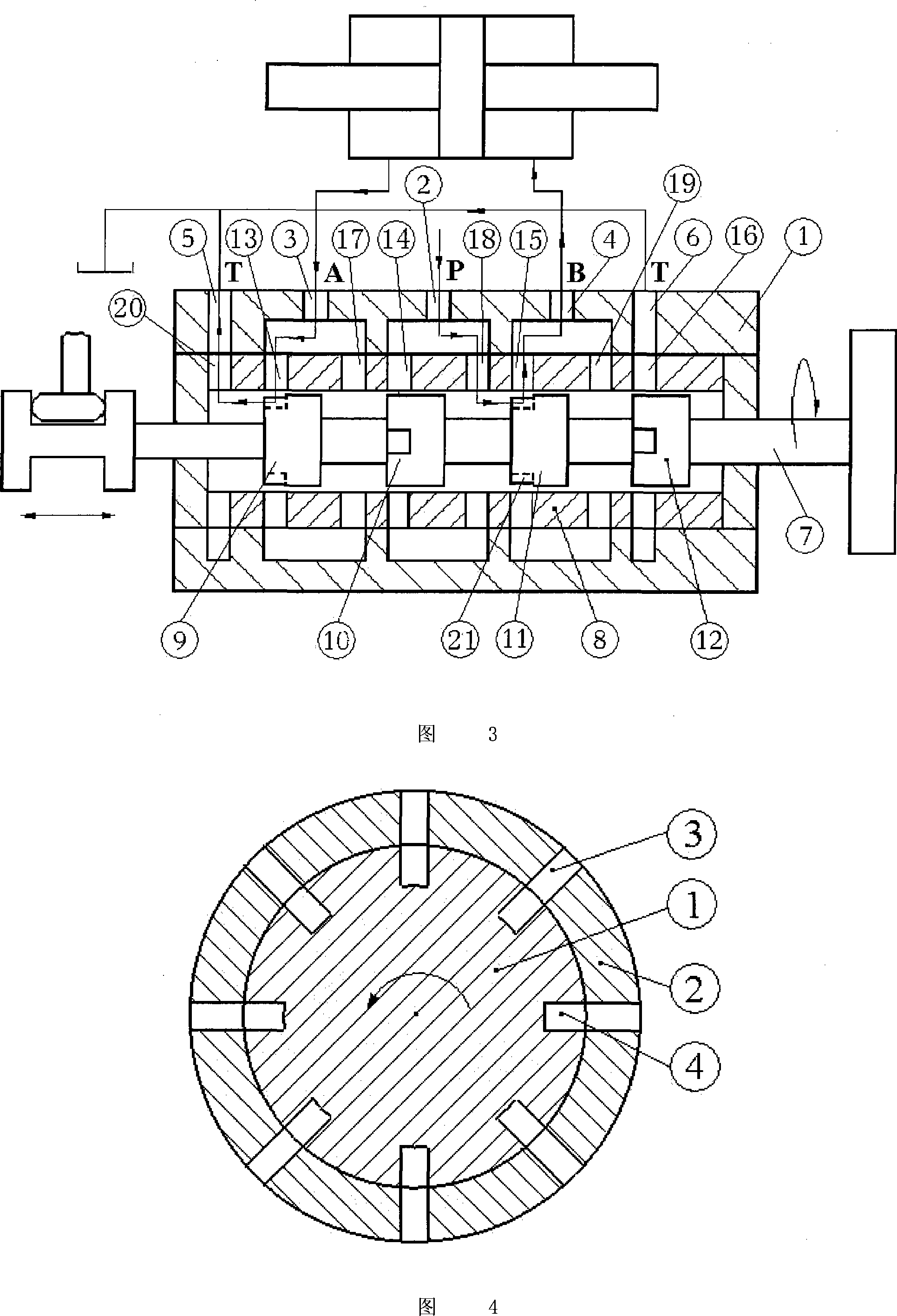

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] 2-7, an electro-hydraulic vibration control valve includes a valve body 1. The valve body 1 is provided with an oil inlet 2 communicating with a high-pressure oil tank 2 and a first oil inlet communicating with a hydraulic cylinder. 3. The second oil inlet and outlet 4, the first oil outlet 5 and the second oil outlet 6 connected to the oil return tank, the electro-hydraulic vibration control valve also includes a valve core 7 and a valve sleeve 8. The valve The sleeve is nested on the inner wall of the valve body, the valve core passes through the valve sleeve, and the valve core is connected with a first servo motor for driving the valve core to rotate and a second servo motor for driving the valve core to move axially; At least four shoulders are equally spaced on the valve core, including a first shoulder 9, a second shoulder 10, a third shoulder 11, and a fourt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com