Air cylinder type injection valve

An injection valve and cylinder type technology, applied in the field of injection valves, can solve problems such as switch failure, waste of rolling oil, and failure of gas valves to work normally, and achieve easy maintenance, lower requirements for gas source pressure, and prevent oil and gas channeling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

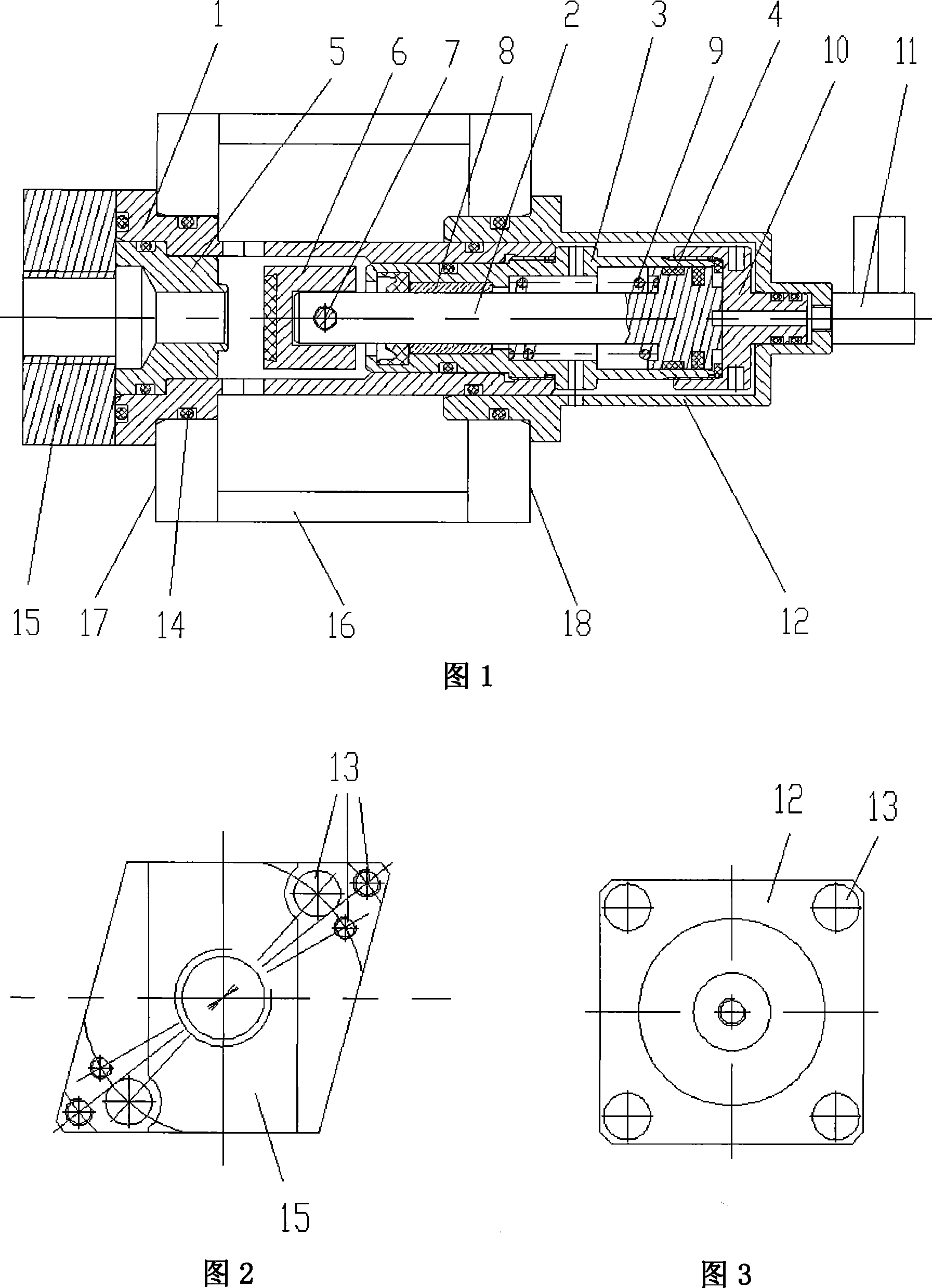

[0023] As shown in Figures 1, 2 and 3, the present invention discloses a cylinder-type injection valve, which is attached to the injection beam 16 and installed. The entire injection valve consists of a valve seat 1, a valve core 2, a cylinder block 3, a guide belt 4, and a valve head. Seat 5, valve head 6, cylindrical pin 7, copper sleeve 8, spring 9, cylinder head 10, valve seat 12, nozzle seat 15 and some sealing rings 14 etc. composition. The valve seat 1 and the valve head seat 5 are fixedly connected to each other, the valve core 2 and the valve head 6 can move relative to the valve head seat 5, the valve core 2 is slidingly arranged inside the cylinder block 3, and the cylinder head 10 is fixed on the cylinder block 3 one end.

[0024] The nozzle seat 15 and the valve seat 1 are fixedly connected by screws 13 and then fixed to the front end 17 of the injection beam 16 together. The valve seat 1 passes through the injection beam 16 and extends into the inside of the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com