Covering type composite vacuum electroosmosis, method for forced ramming reinforcing foundation and device thereof

A covered and electroosmotic technology, which is applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of not being able to prevent rainwater recharge, high vacuum attenuation of vacuum system, and being easily disturbed by weather factors, etc., to solve the problem of weather Interference of factors, easy construction and operation, and the effect of widening the selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

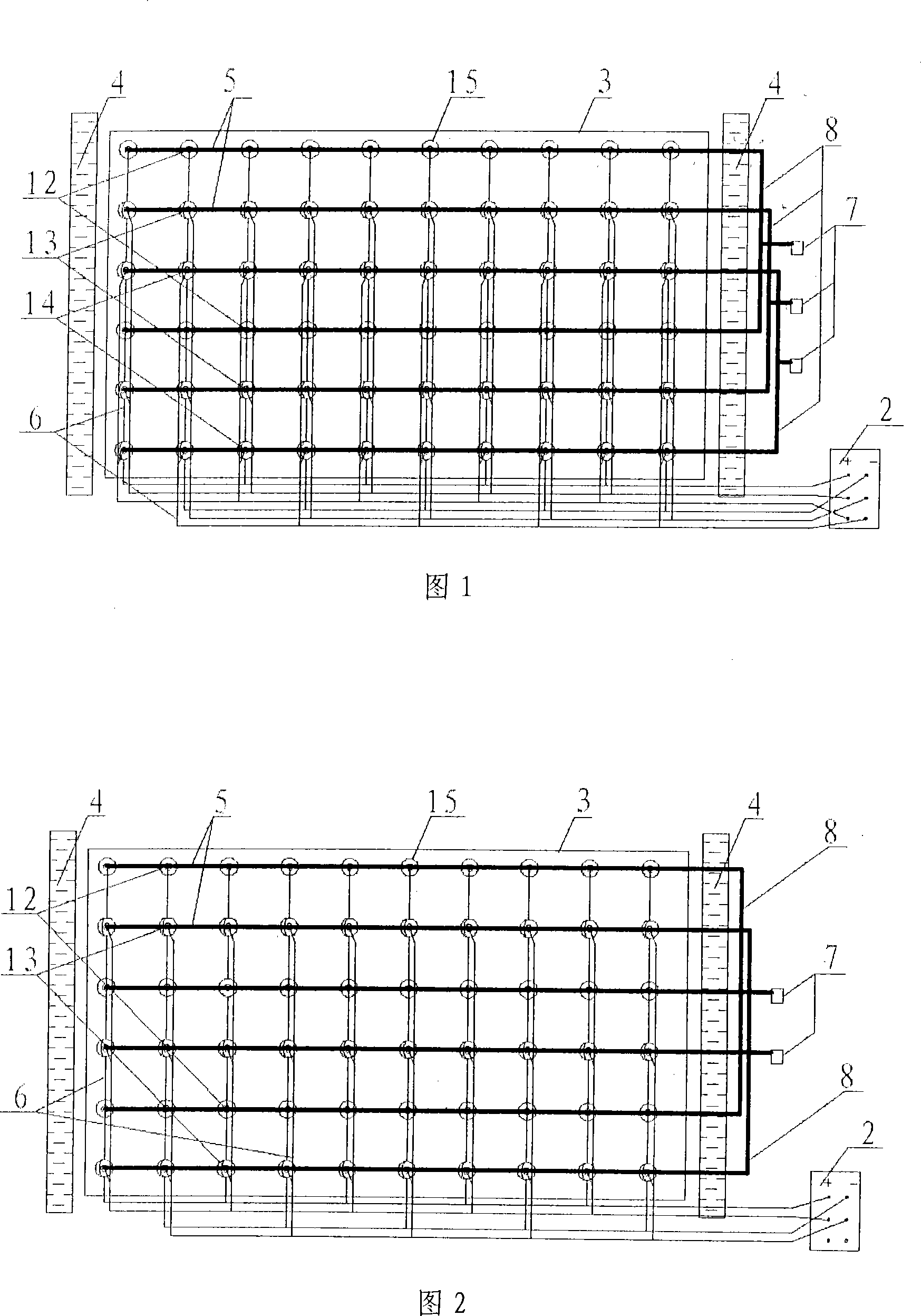

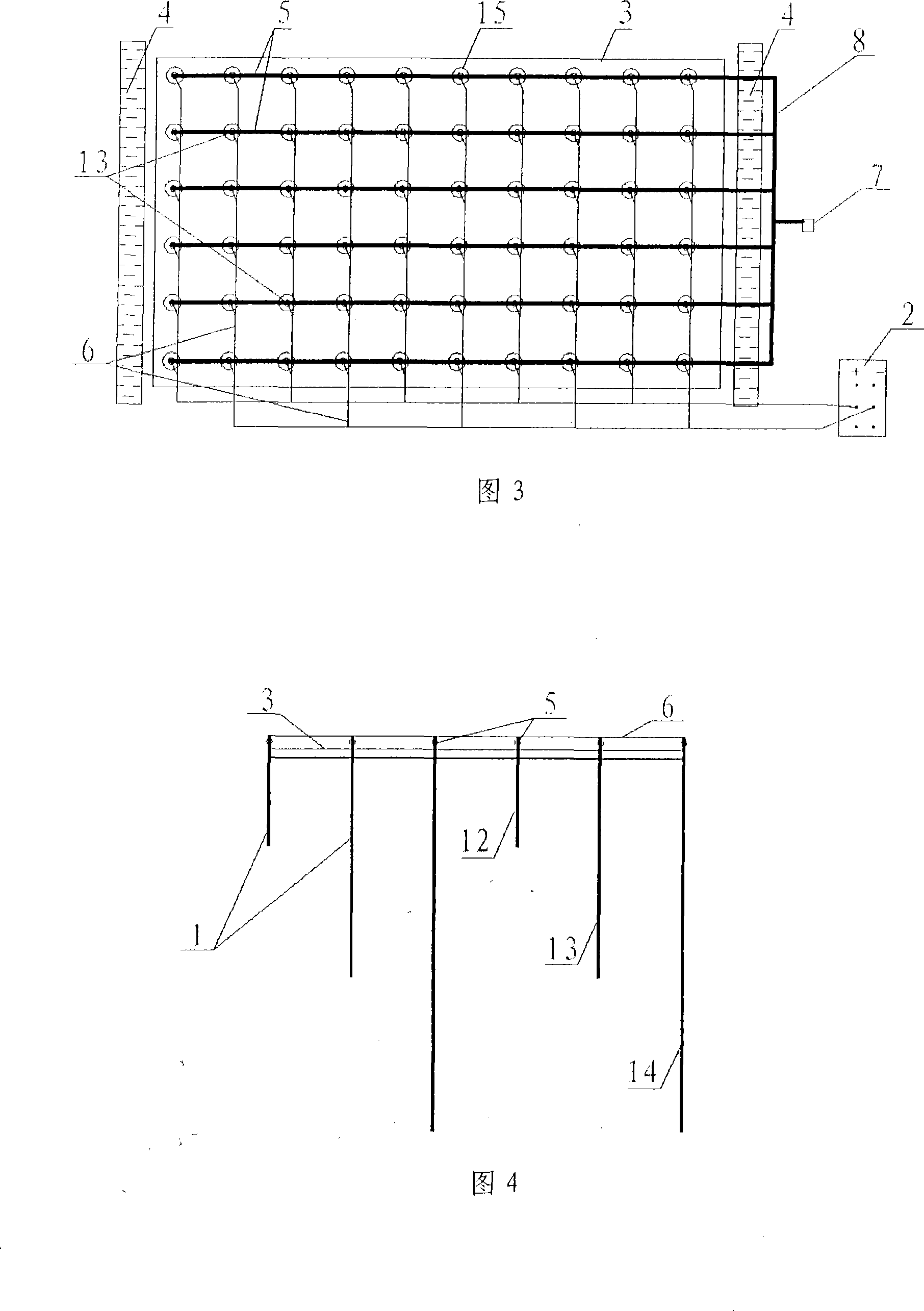

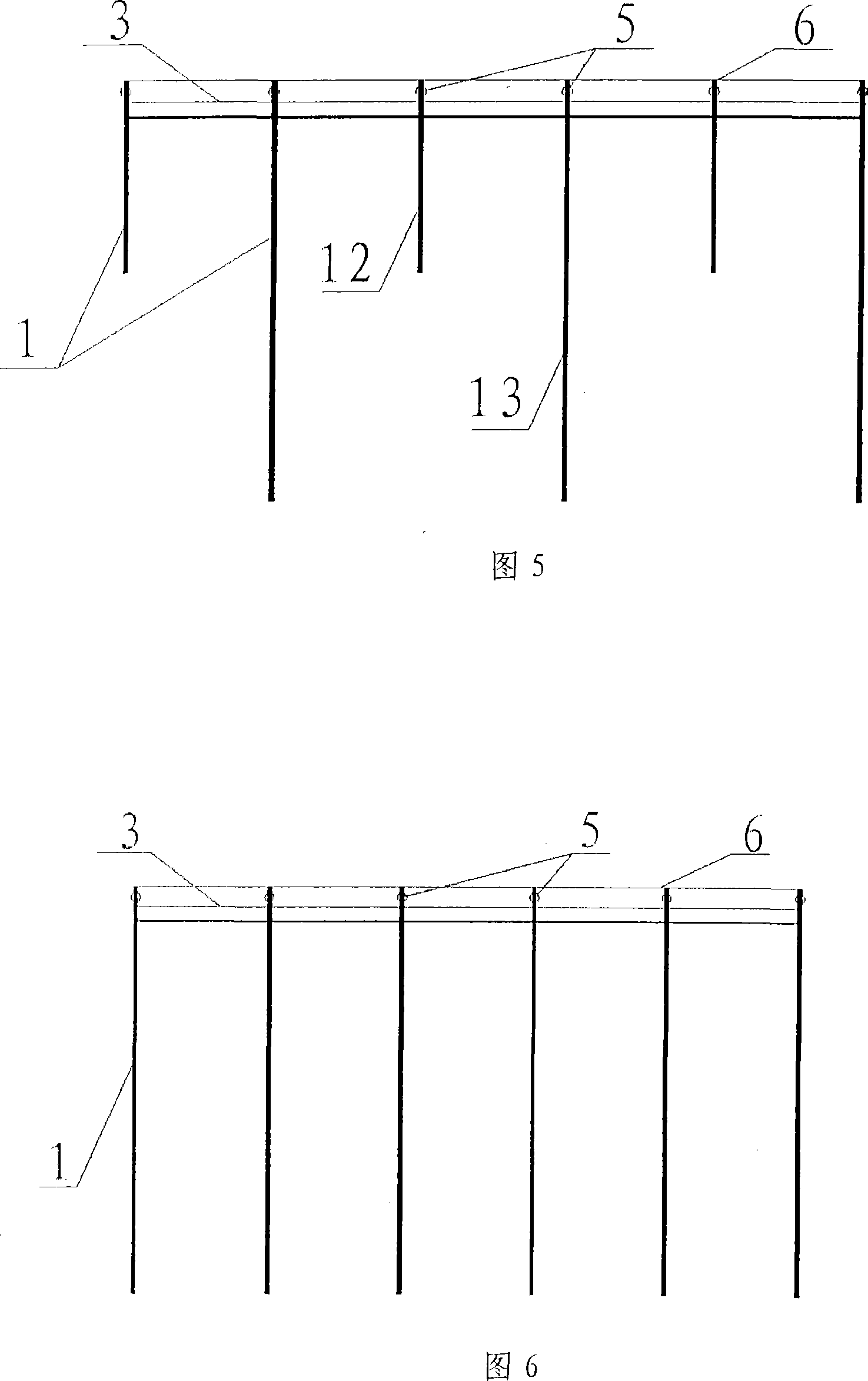

[0069] Embodiment 1: See accompanying drawing 1, accompanying drawing 4, accompanying drawing 7, accompanying drawing 8, and accompanying drawing 9 shown,

[0070] At a test site in Zhejiang, the treatment depth is required to be 11m

[0071] 1. Roughly level the site after entering the site, remove sharp objects, and carry out the construction and lofting of the composite pipe position on the flat surface according to the mesh distribution of the mesh cap eyelet film. The mesh spacing is set to 0.5 meters.

[0072] 2. Carry out detailed exploration of small screw drilling in the test area, and drill to a depth of not less than 11 meters below the surface. Due to the small area of the test area, 25m×25m grid holes are used for small screw drilling detailed exploration, and well prepared Record. Find out the embedment depth and thickness of various soil layers in the test area, so as to know the soil properties, soil water content, permeability coefficient and endowment stat...

Embodiment 2

[0087] Embodiment two: see accompanying drawing 2, accompanying drawing 5, accompanying drawing 7, accompanying drawing 9, accompanying drawing 10 and accompanying drawing 11 shown,

[0088] Same as Example 1, in a test site in Zhejiang, the treatment depth is required to be 7m

[0089] 1. After entering the site, the site should be roughly leveled, sharp objects should be removed, and the position of the composite pipe should be set out on the flat surface. The distance between the composite pipes should be set at 0.5 meters.

[0090] 2. Carry out detailed exploration of small screw drilling in the test area, and drill to a depth of not less than 7 meters below the surface. Due to the small area of the test area, 25m×25m grid holes are used for small screw drilling detailed exploration, and well prepared Record. Find out the embedment depth and thickness of various soil layers in the test area, so as to know the soil properties, soil water content, permeability coefficient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com