Bottom rising device of knitting horizontal machine

A technology of flat knitting machine and bottom plate is applied in the directions of knitting, weft knitting, textile and paper making, etc. It can solve the problems such as affecting the overall knitting effect of the garment piece, reducing the overall work efficiency, and greatly affecting the product quality, etc. efficiency and work efficiency, simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

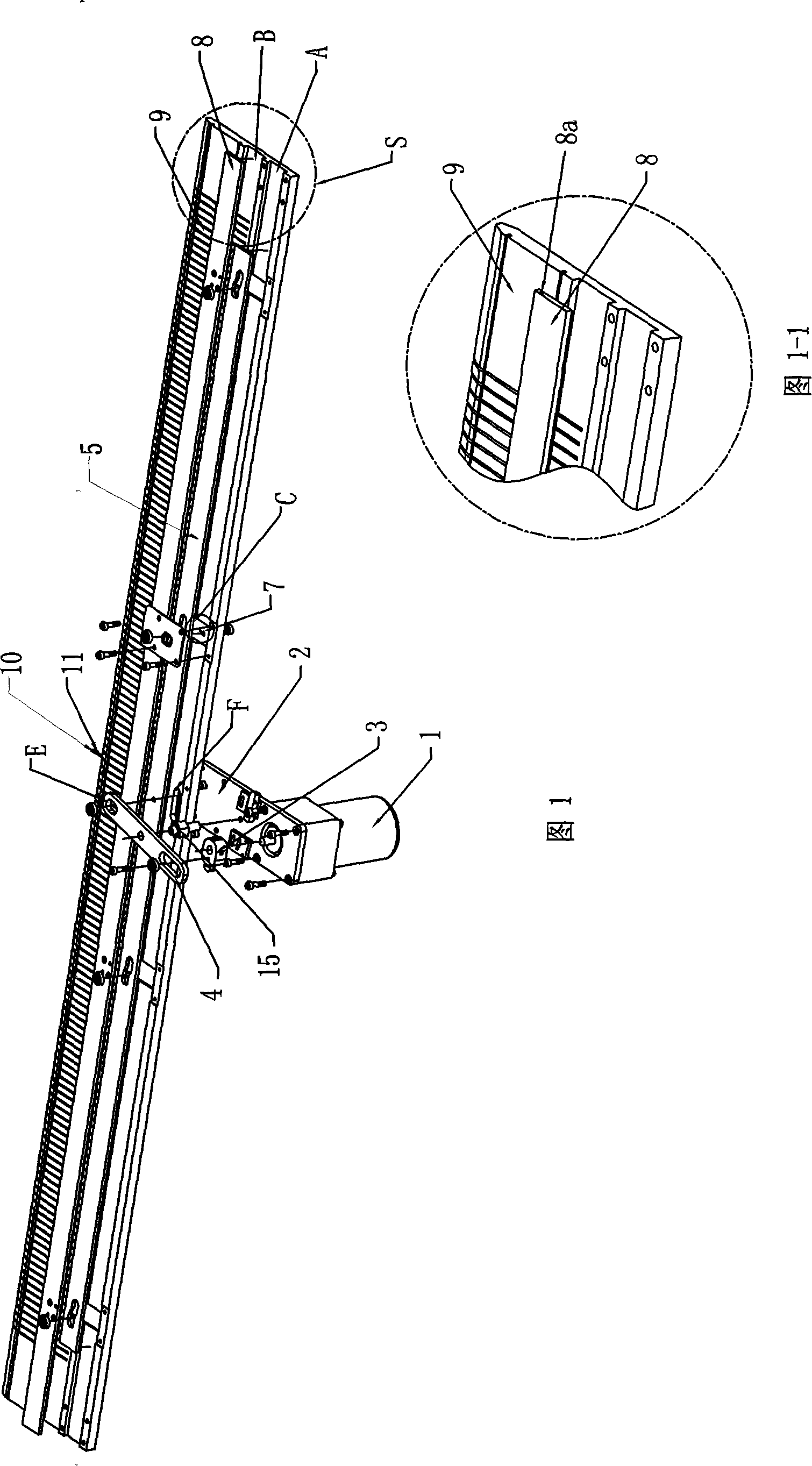

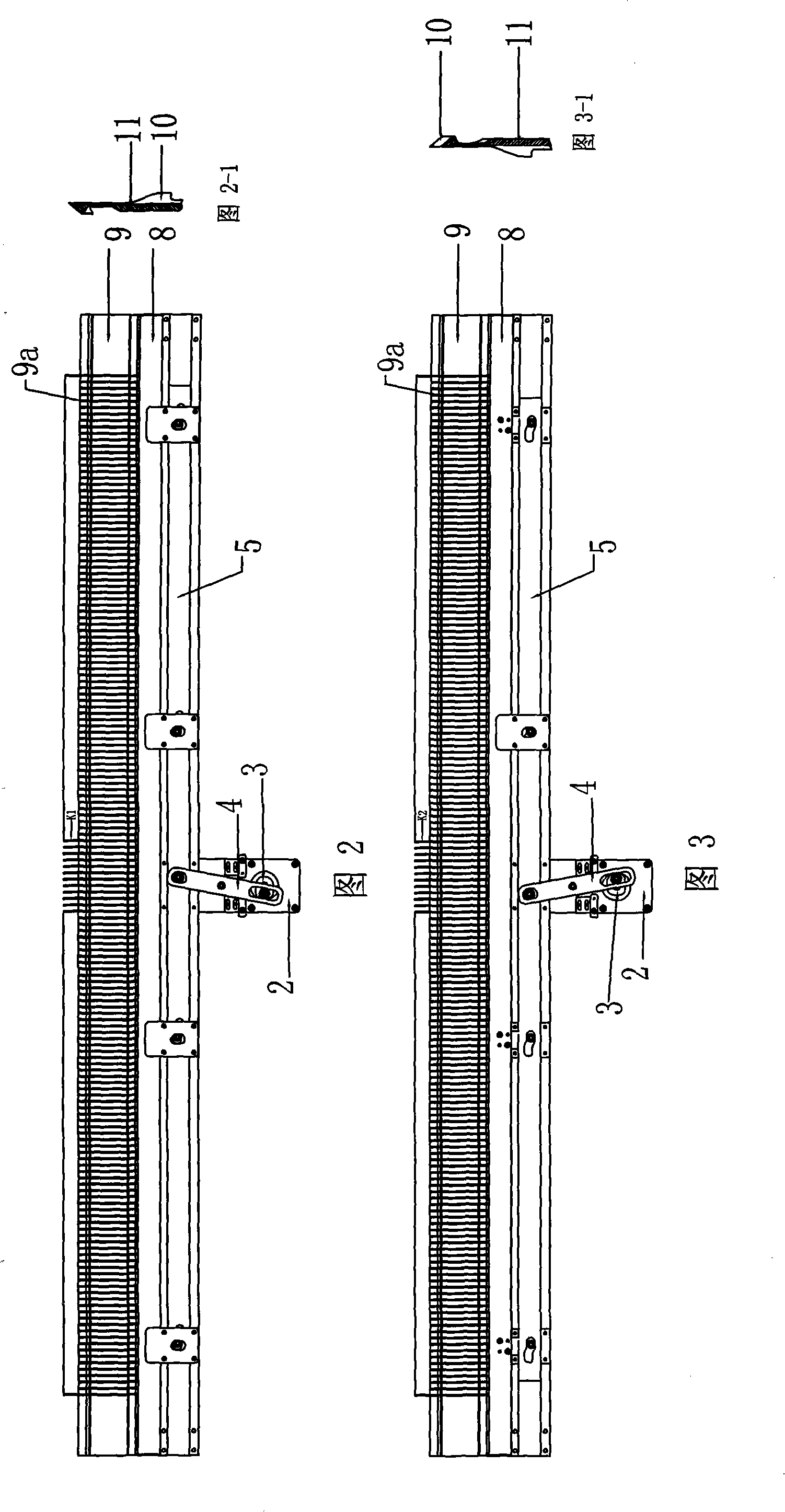

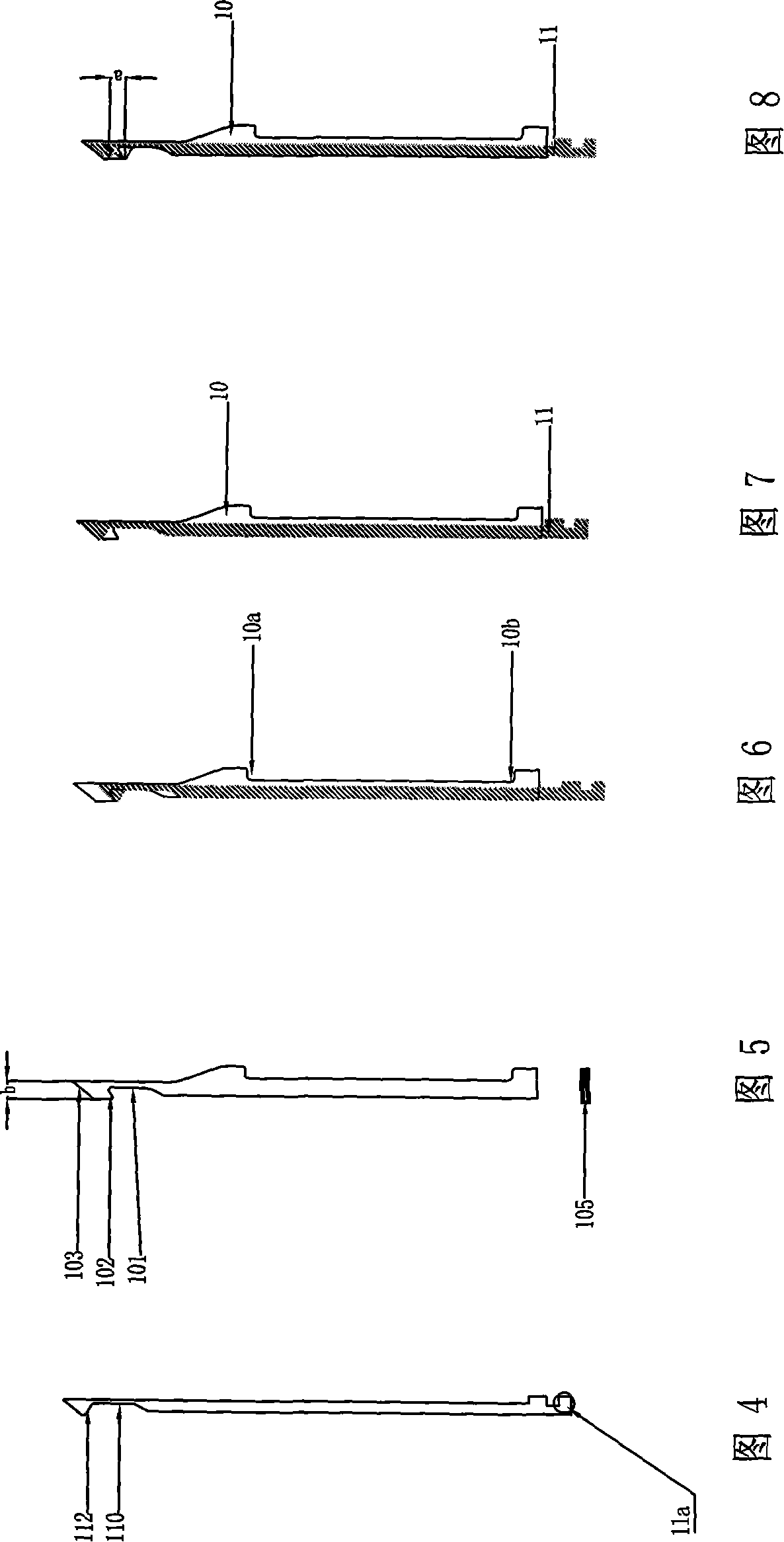

[0029] As shown in the figure, the lifting device of a flat knitting machine is composed of a lifting plate, a needle and a transmission part, and the lifting plate part is mainly composed of a swing rod motor 1, a swing rod cam 3, a swing rod 4, a connecting rod 5, a connecting plate 7, The control board 8, the lifting needle plate 9, the crochet needle 10, the yarn withdrawal rod 11, etc. are composed of the swing rod motor 1 in the bottom lifting device installed on the swing rod motor seat 2, as shown in Figure 2 is the front of the bottom lifting device, the motor seat 2 is fixedly installed on the back side of the bottom lifting needle plate 9. A swing cam 3 is installed on the shaft at one end of the swing rod motor 1. The cam 3 is slidably connected with the swing rod 4 through a bearing. When the swing rod motor 1 is running, the swing rod 4 is The shaft 15 is the movement of the axis. Similarly, there is a built-in bearing in the oblong hole E at one end of the pendul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com