Neodymium-iron-boron cylindrical form permanent magnetic material with longitudinal through-hole molding method and special moulds

A technology of permanent magnet materials and longitudinal through holes, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of long production cycle, high drilling cost, product performance stability and unsatisfactory product quality, and achieve Reduce tool consumption cost and labor cost, improve stability and product quality, ideal effect of stability and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

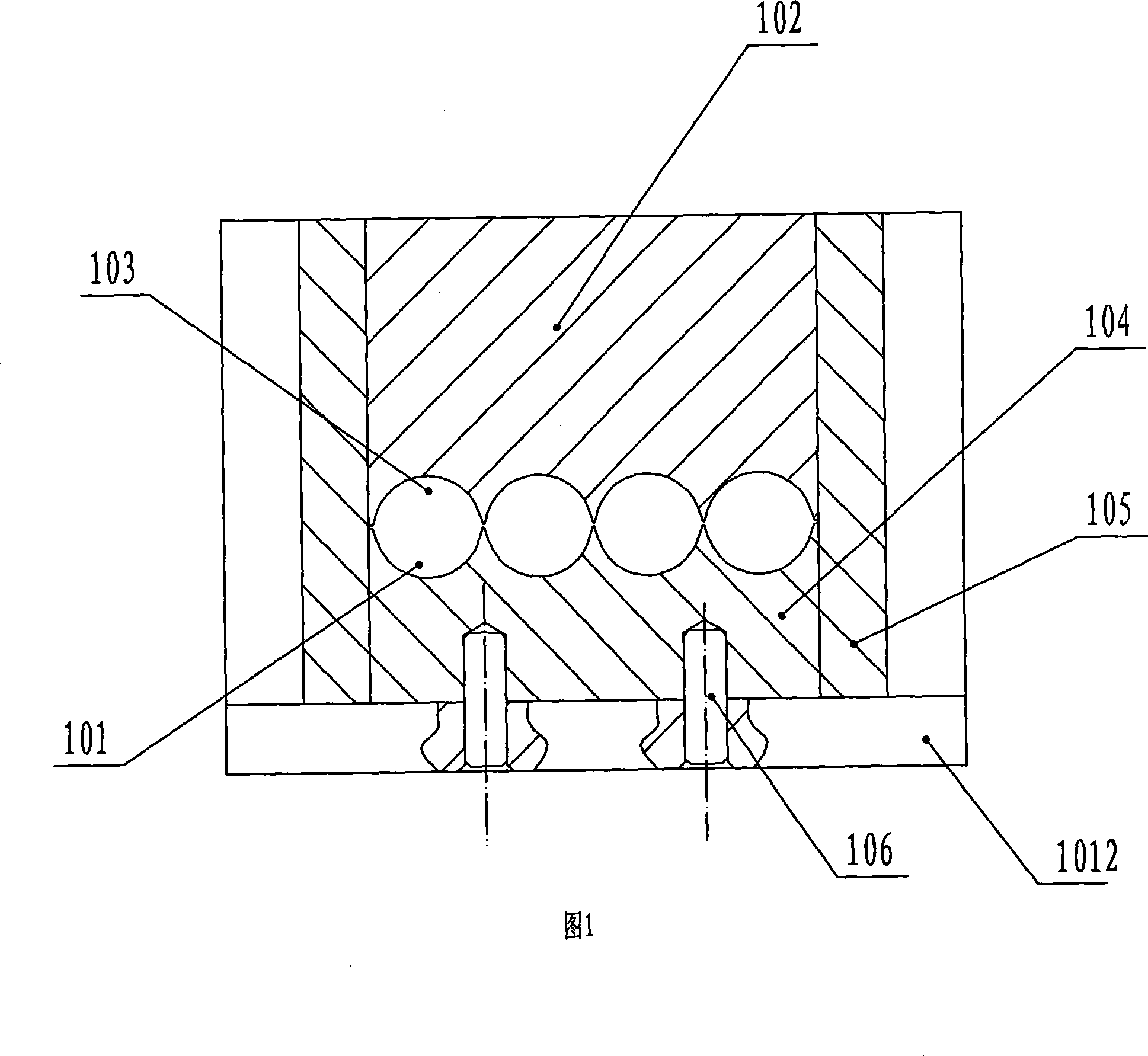

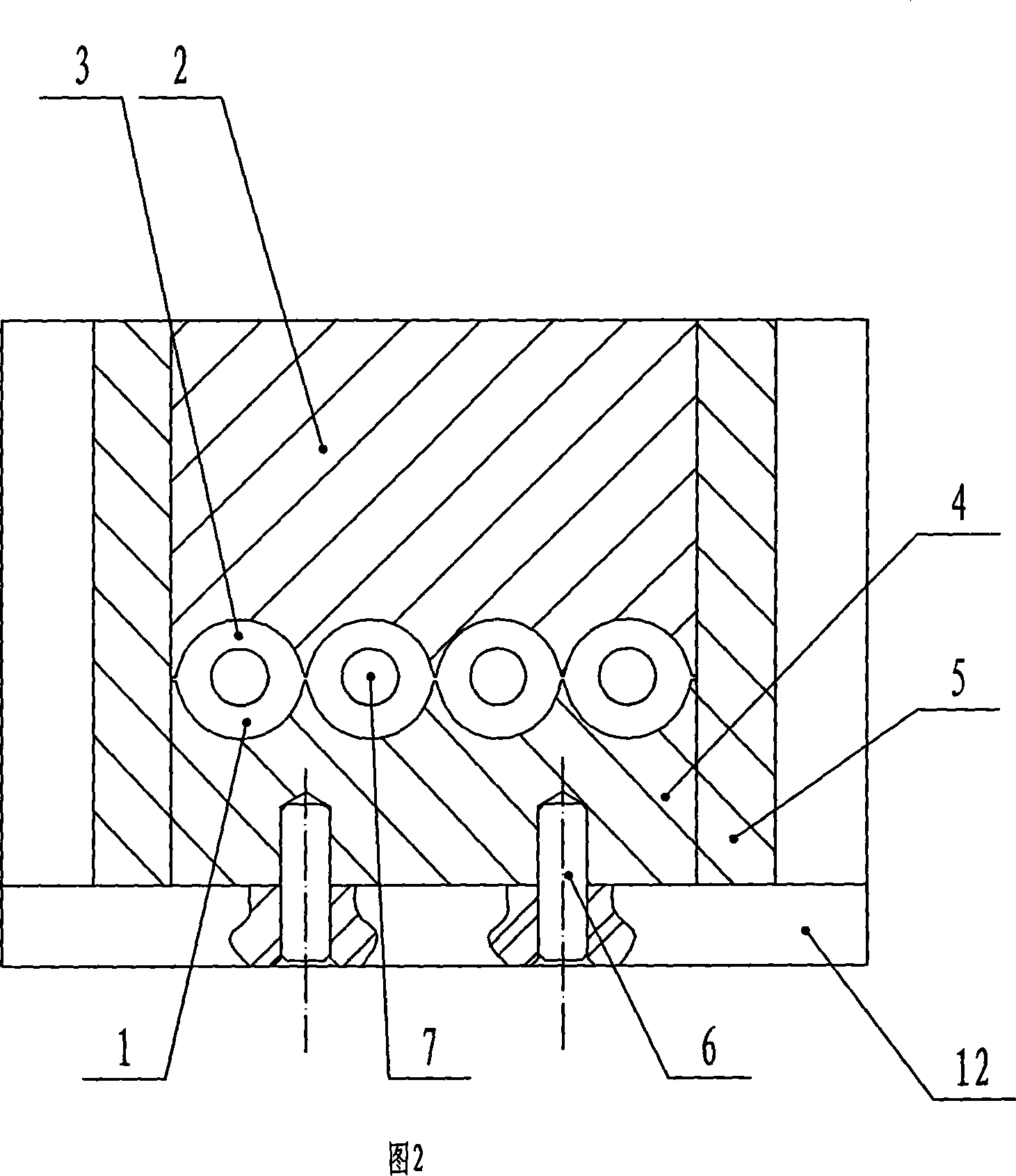

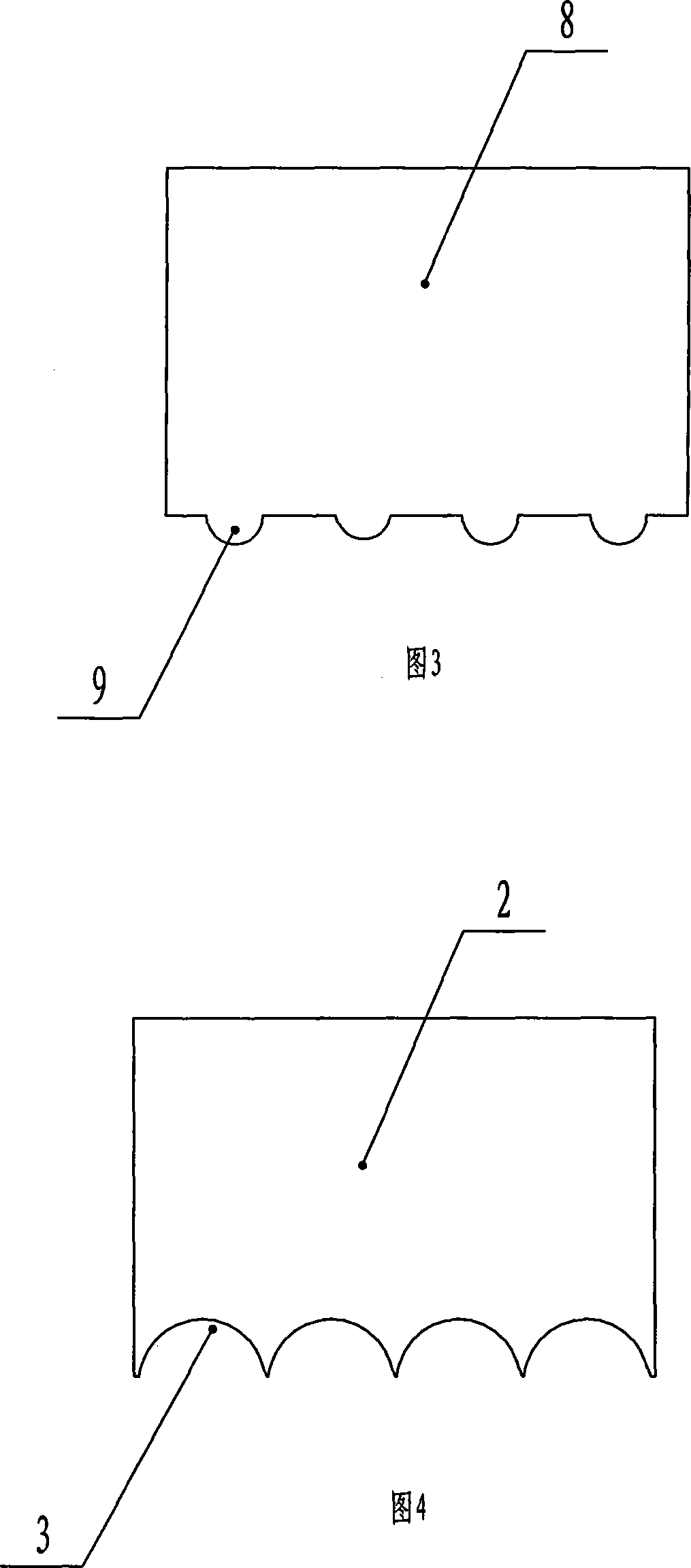

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0037]The manufacturing method of the NdFeB cylindrical permanent magnet material with the longitudinal through hole of the present invention is different except that the key step of obtaining the longitudinal through hole is different, that is, except that the forming step is different and the longitudinal drilling step of the drilling machine has been cancelled, the rest of the manufacturing process The steps are the same as the existing technology: raw material batching→vacuum smelting into alloy ingots→crushing and grinding machine to make fine particles→jet milling into powders with required fineness→forming on magnetic field forming press (the differences are detailed below) →Vacuum packaging→Store in a vacuum container after isostatic pressing→Sintering in a vacuum sintering furnace→Surface smoothness treatment→Cutting into shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com