Method of soldering and cutting as well as connecting by ultrasound wave

An ultrasonic, welding and cutting technology, used in sewing tools, household components, household appliances, etc., can solve the problems of thick interface bulges, rough and unequal connection positions, and achieve high-grade and excellent quality, beautiful and exquisite appearance. Comfortable to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

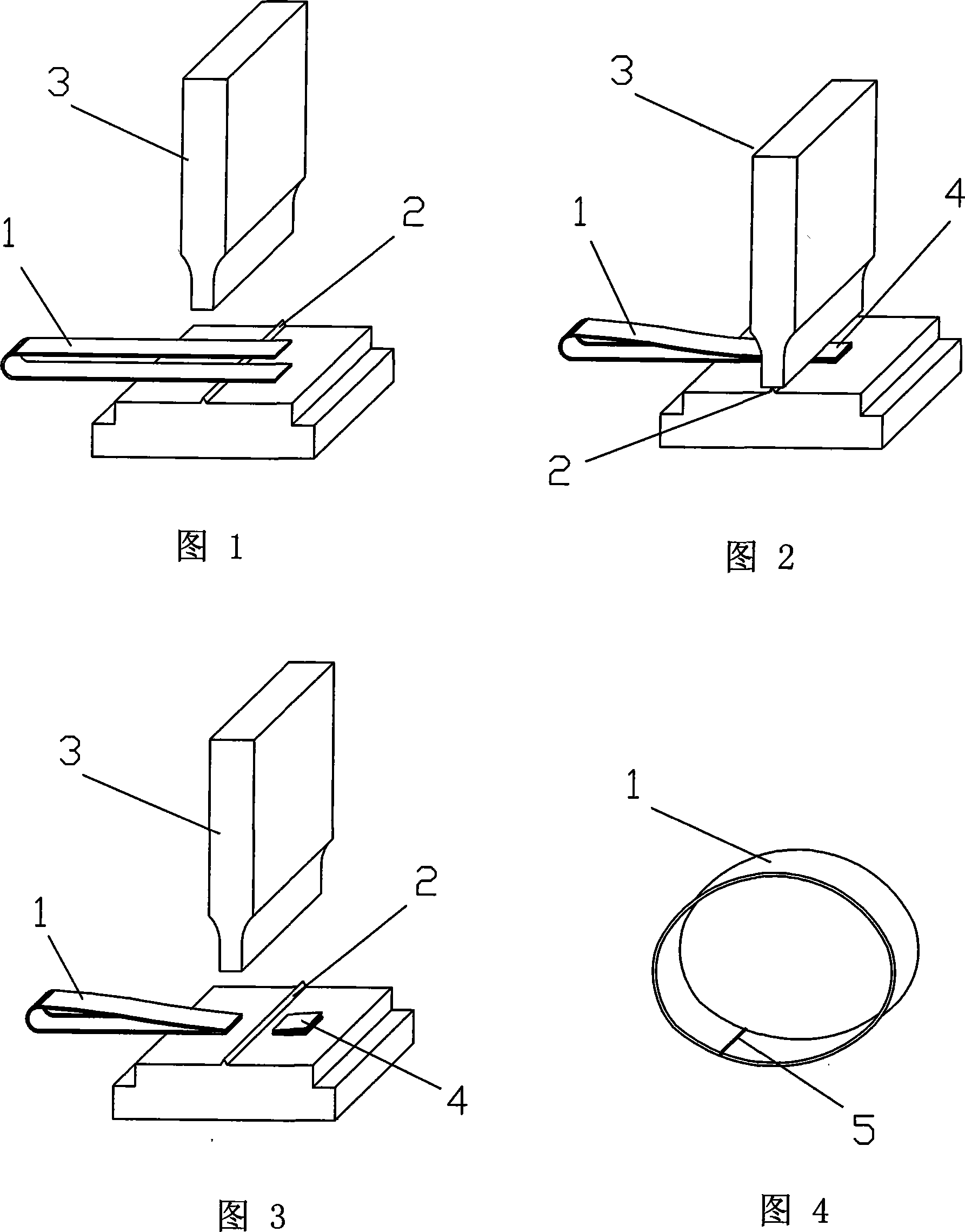

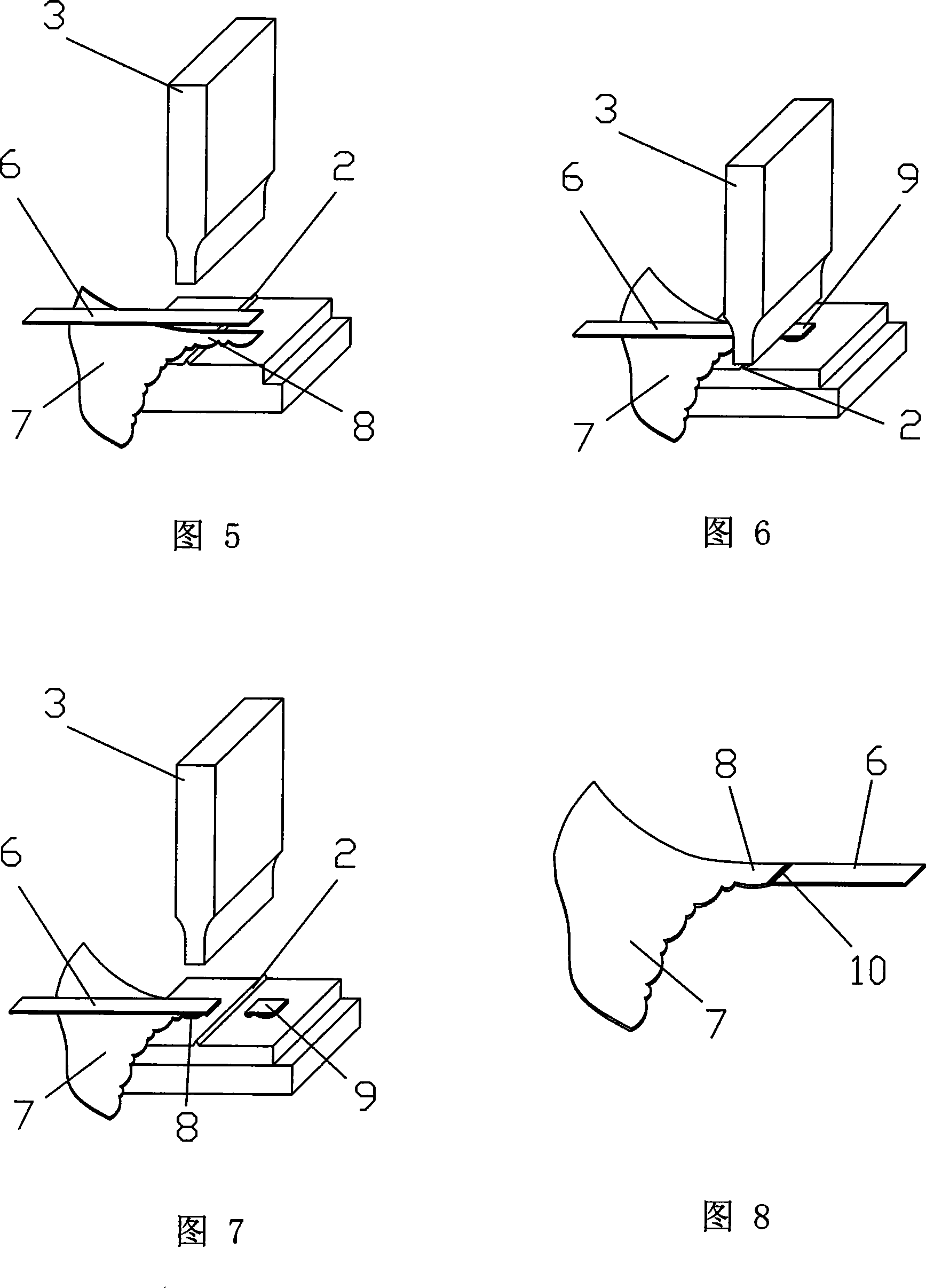

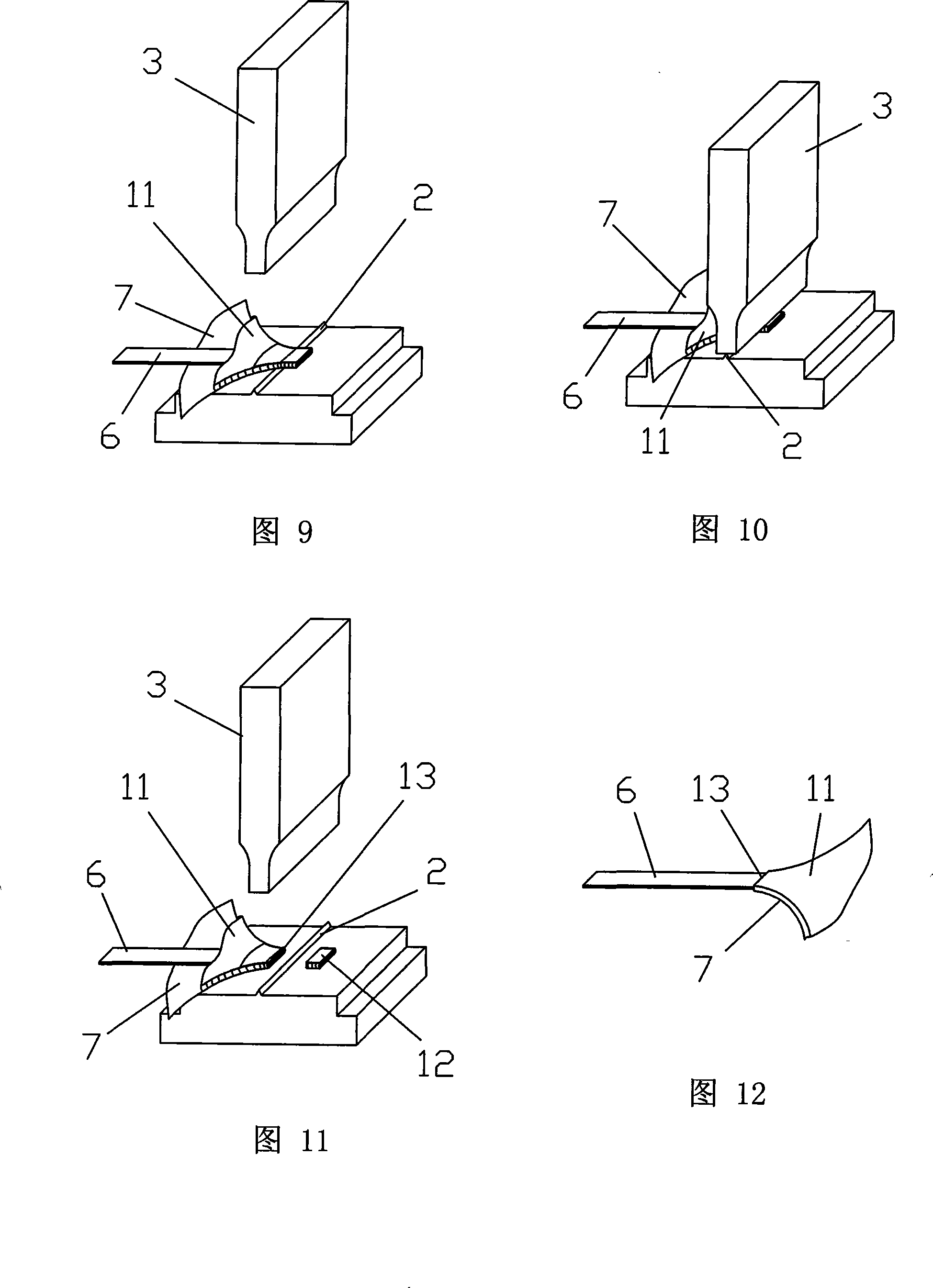

[0023] Fig. 1 to Fig. 4 have shown the technology that first embodiment of the present invention one underwear waist elastic band two ends join, the method for ultrasonic welding and cutting connection of the present invention, comprises the following steps:

[0024] Turn on the ultrasonic welding and cutting machine to emit ultrasonic waves, fold a wide elastic band made of natural fiber and artificial fiber blended fabric in half, make the two ends overlap and level, and put the level head on an ultrasonic welding and cutting machine On the edge 2 of the lower die of the machine (as shown in Figure 1).

[0025] Finally, the knife edge 3 of the upper mold of the ultrasonic welding and cutting machine is pressed down, and the heat generated by the ultrasonic waves emitted on the knife edge of the ultrasonic welding and cutting machine at the contact part with the wide elastic band 1 is used to weld the overlapping ends of the wide elastic band 1 and cut off Excess material hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com