Automatic cycle energy-saving boiling case

A technology of automatic circulation and cooking box, applied in the field of cooking box, can solve the problems of unstable product quality, waste of raw material energy, long production cycle, etc., to overcome pollution and waste of raw material energy, ensure product quality and taste, and improve multi-purpose sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

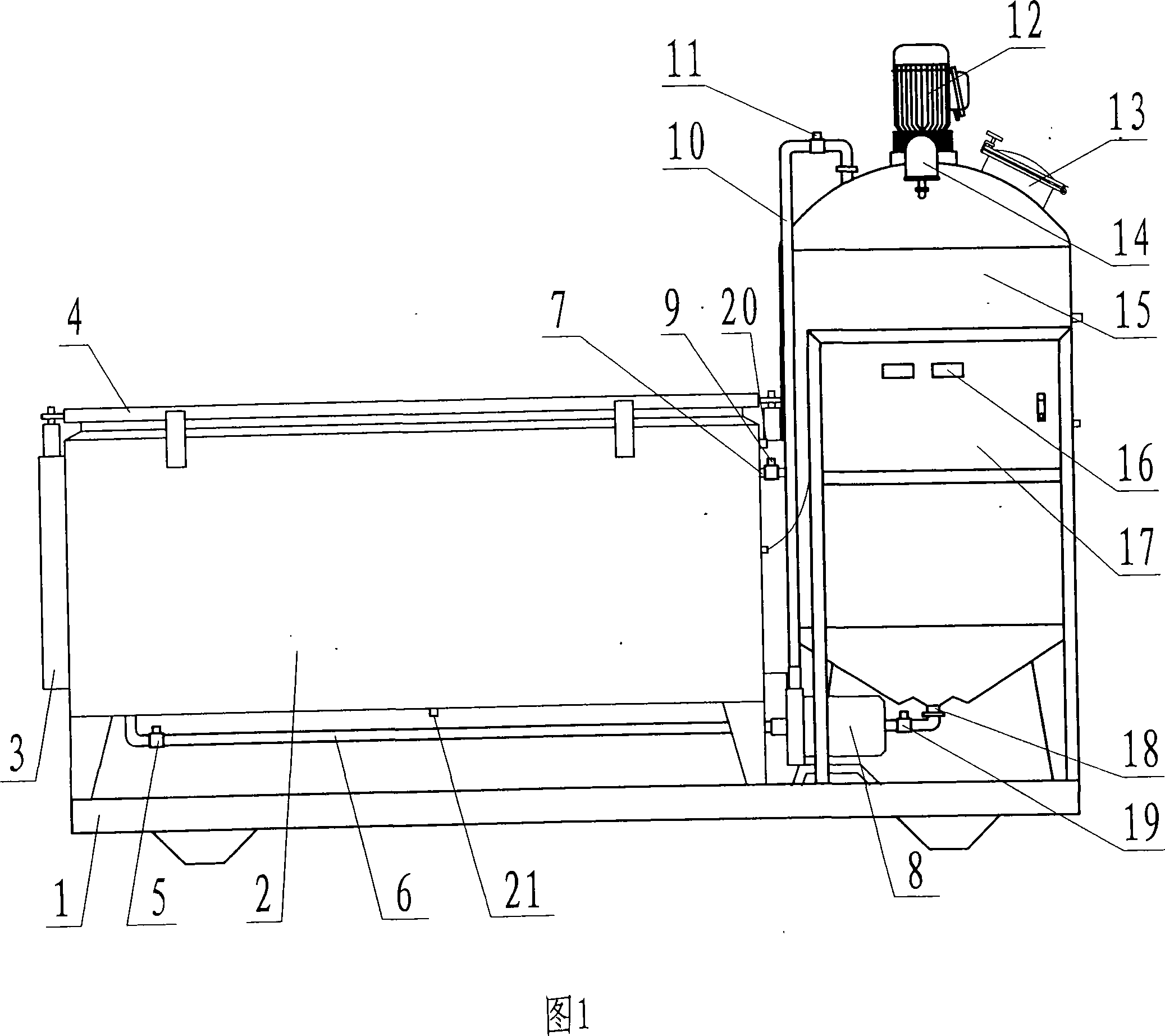

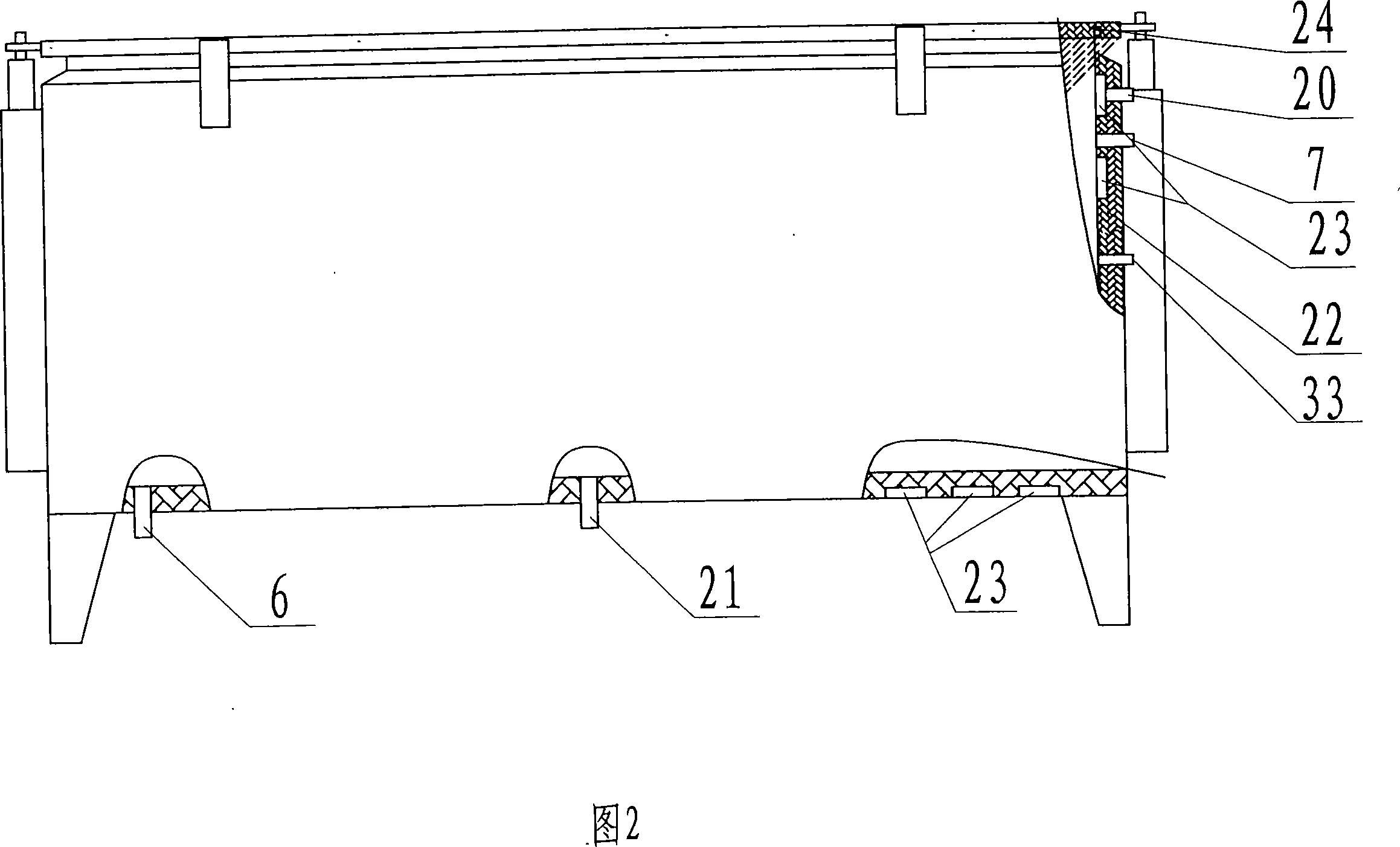

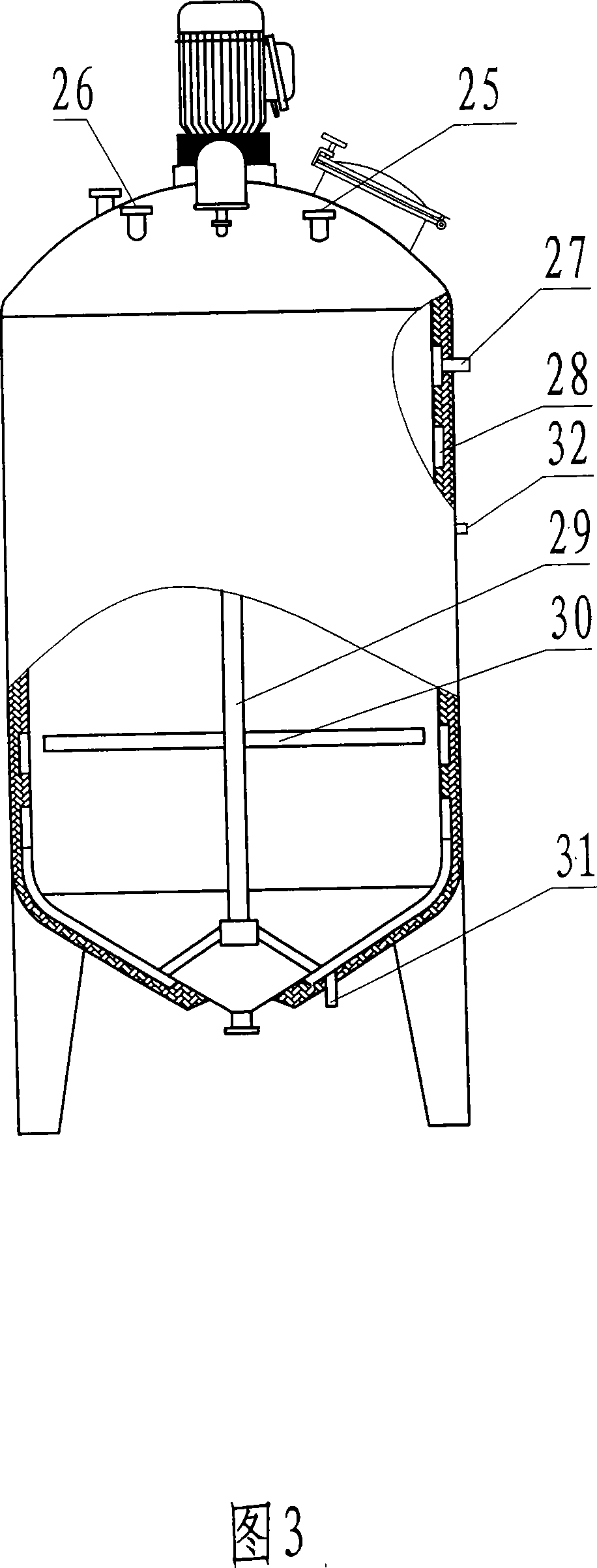

[0012] The present invention is described below in conjunction with accompanying drawing:

[0013] The PLC of the present invention is provided with computer software for the entire cooking and marinating process, and the panel of the electric control cabinet 17 is provided with a touch screen, through which the control process can be set and modified. After the marinade raw material is injected into the raw material tank through the raw material inlet 25 provided on the soup stock preparation tank body 15, the PLC controls the stirring motor 12 through the electric control cabinet 17 to drive the stirring shaft 29 and the stirring blade 30 in the pot to fully mix the stock raw material. After stirring, the PLC controls the circulation pump 8 to start working, and the electromagnetic valves 9 and 19 are opened, and the stirred soup enters the box 2 through the soup input pipe to cook and halogenate the bean products in it, and at the same time, the PLC controls the steam to con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com