Finishing machine image positioning control system and control method thereof

A control system and image positioning technology, applied in the direction of comprehensive factory control, electrical program control, use feedback control, etc., can solve the problems of shortening the service life of related components, reducing the production safety factor, frequent start-up of finishing machines, etc., and achieve improvement type and range, enabling serialization and automation, compact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

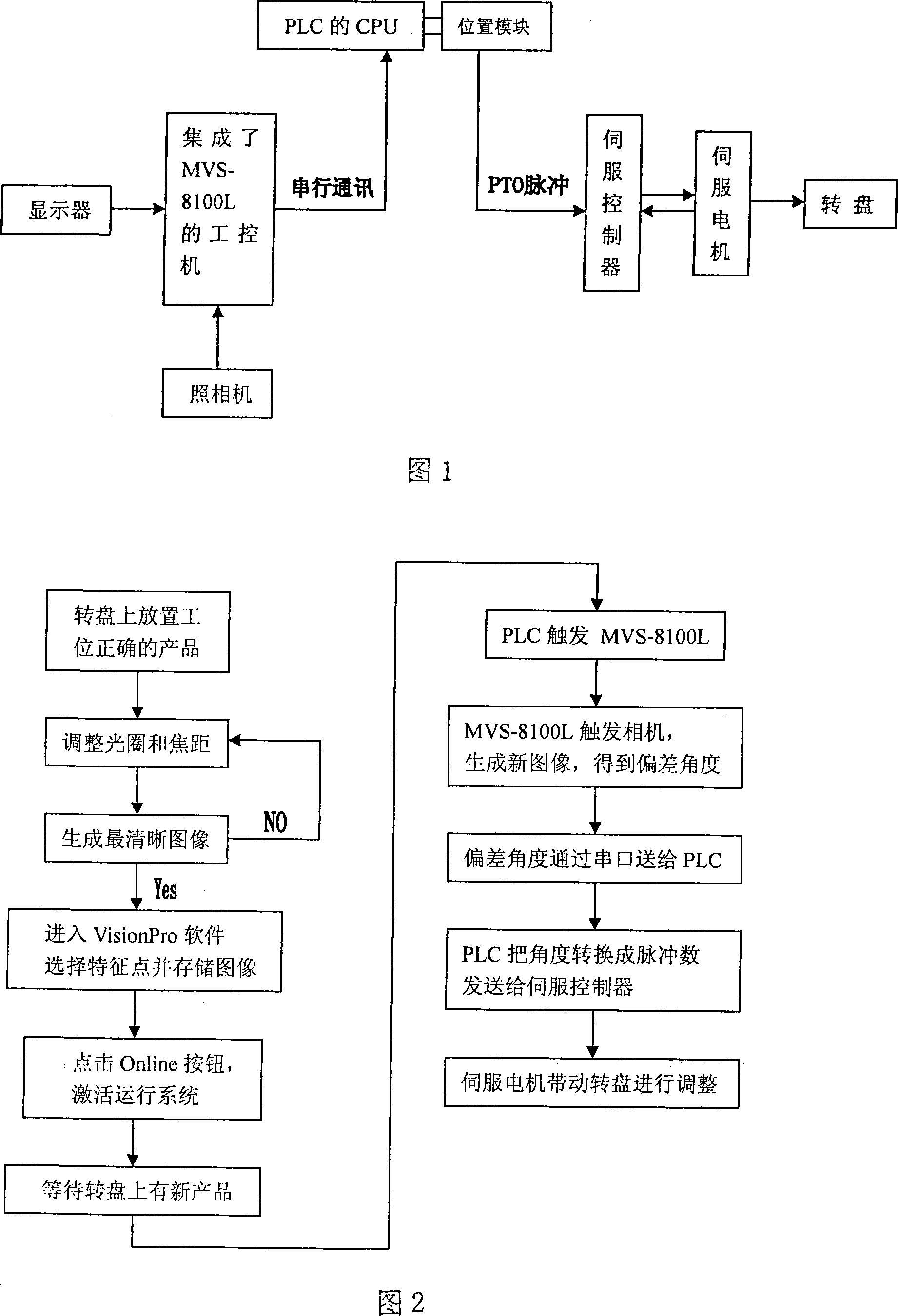

[0019] Referring to accompanying drawings 1-3, the finishing machine image positioning control system is mainly composed of a finishing machine image mechanism, a programmable logic controller (PLC), a servo drive device and a feeding mechanism. The image mechanism of the finishing machine adopts the integrated system of Cognex, the programmable logic controller (PLC) adopts Siemens S7-200, and the servo drive device adopts the Delta (ASDA) series.

[0020] The image mechanism of the finishing machine adopts the integrated system of Cognex, which is mainly composed of image processing integrated board chip MVS-8100L, industrial computer, camera, backlight and display; the image processing integrated board chip MVS -8100L is the core of the image mechanism of the finishing machine. It is inserted into the industrial computer through the PCI card slot. The industrial computer adopts ADLINK, the display is a 17-inch Philips LCD monitor, and the camera adopts Sony XC-ST50 with a pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com