Curtain wall unit hanging equipment and construction method thereof

A curtain wall unit and hoisting equipment technology, applied to walls, building components, buildings, etc., can solve the problems of low curtain wall hoisting efficiency, high construction cost, and high accident rate, so as to reduce construction cost and accident rate, save labor, The effect of reducing construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

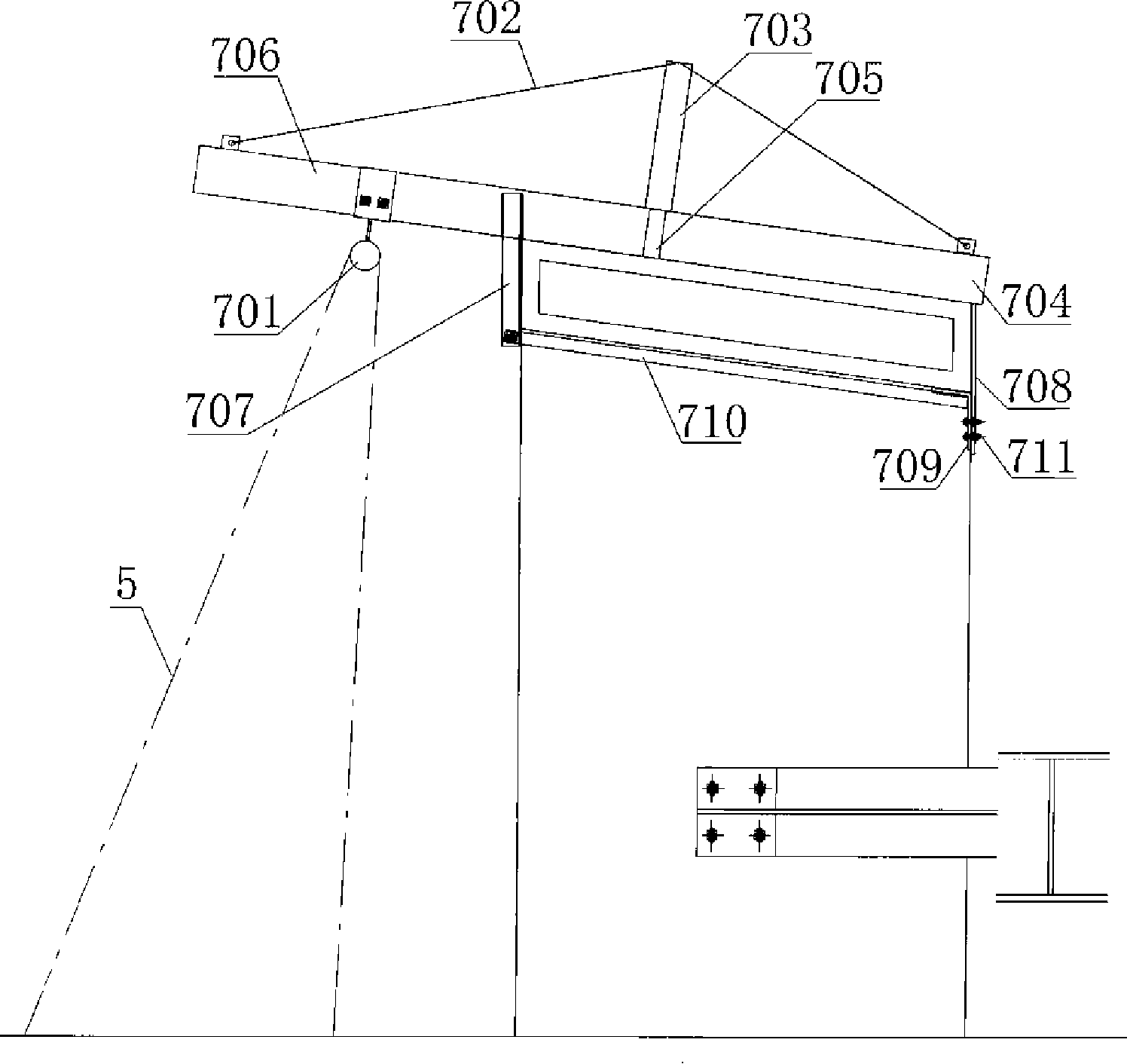

[0034] The embodiment of this curtain wall unit hoisting equipment sees Figure 1-4 As shown, it includes 1-2 winches fixed on the ground 2, 1-2 hoisting frames and 1-2 wire ropes fixed on the top of the wall 3, one end of the wire rope 5 is connected with the hoist drum 603, and the other end The fixed pulley 701 bypassing the hoisting frame is connected to the top of the curtain wall unit 1 and then connected to the manual hoist 9 .

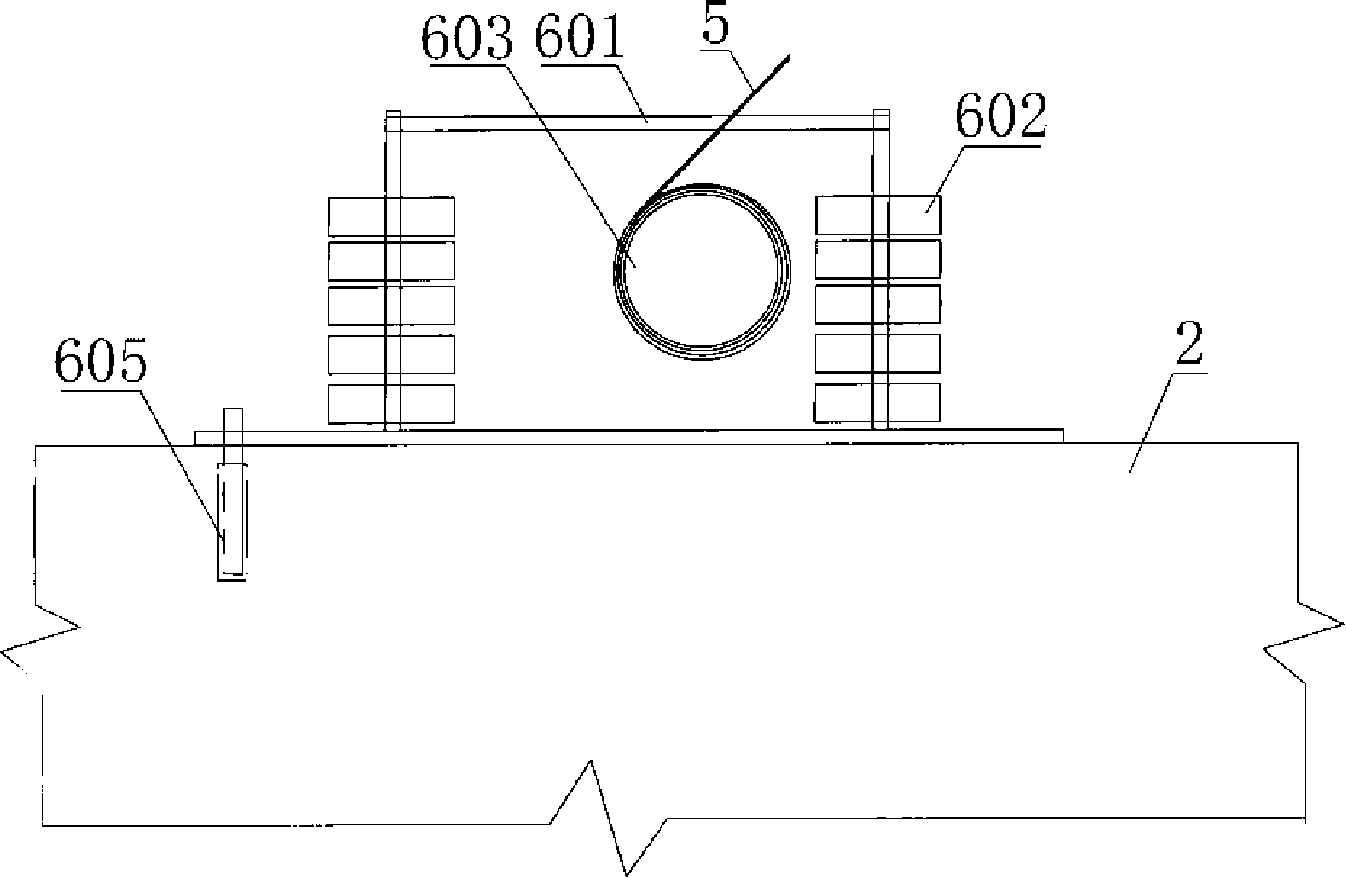

[0035] Hoist embodiment one see figure 1 The hoist 6 includes a hoist bracket 601, a hoist counterweight 602, a hoist drum 603, and a hoist fixture. The hoist fixture may be two M12 expansion bolts 605 that the hoist 6 connects to the concrete floor 2.

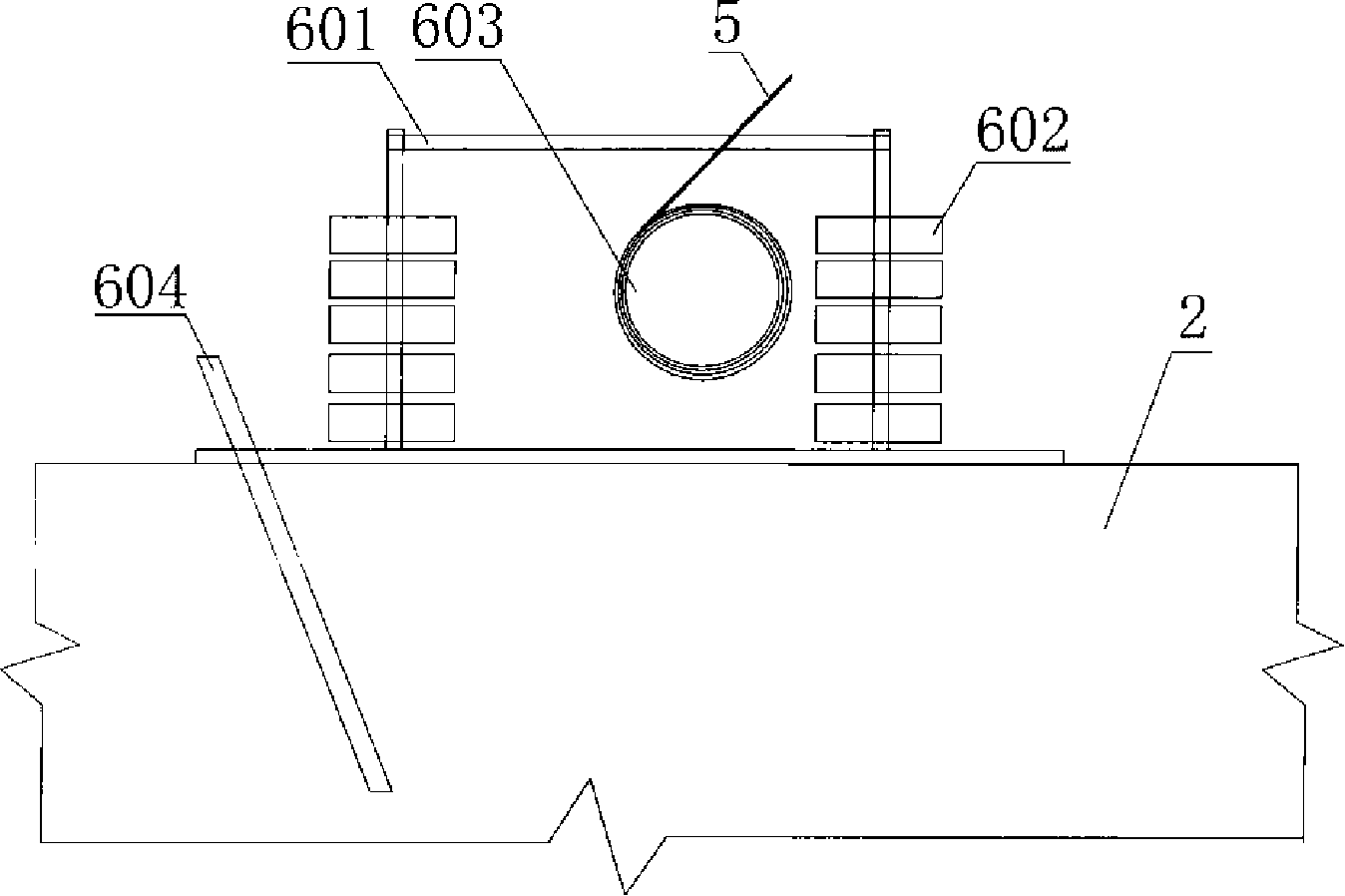

[0036] Hoist embodiment two see figure 2 , the above-mentioned hoist fixture can be 4 steel pipes or thick steel bars 604 that hoist 6 connects to the earthy ground 2, and the depth of implantation is 400mm, and the hoist is tied on the steel pipe or thick steel bar to prevent the hoist from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com