Brake control device for elevator

A brake control and elevator technology, which is applied in hoisting devices, transportation and packaging, elevators, etc., can solve the problem of not using two windings to continuously control the winding current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0137] Embodiments of the present invention will be described below with reference to the drawings.

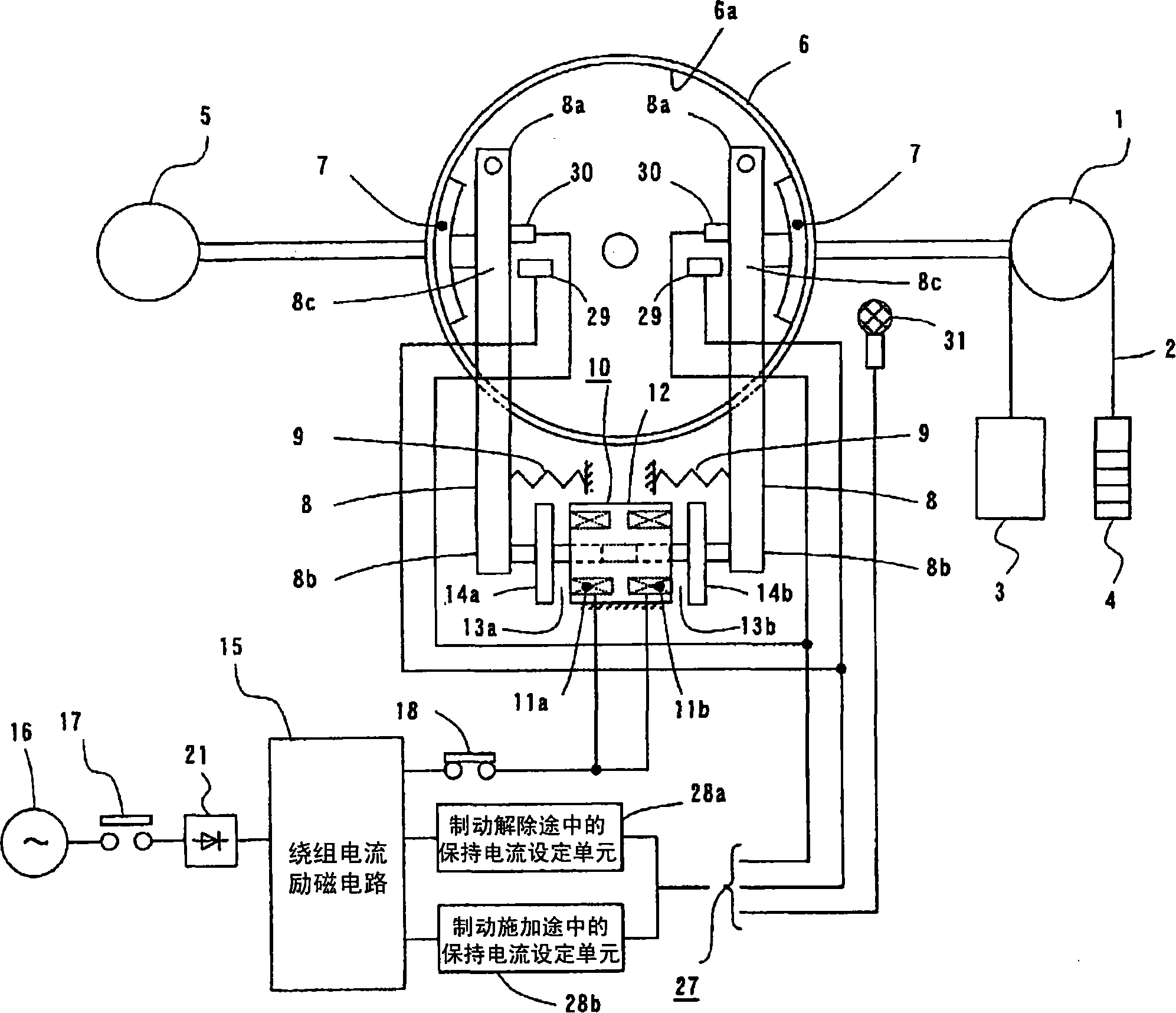

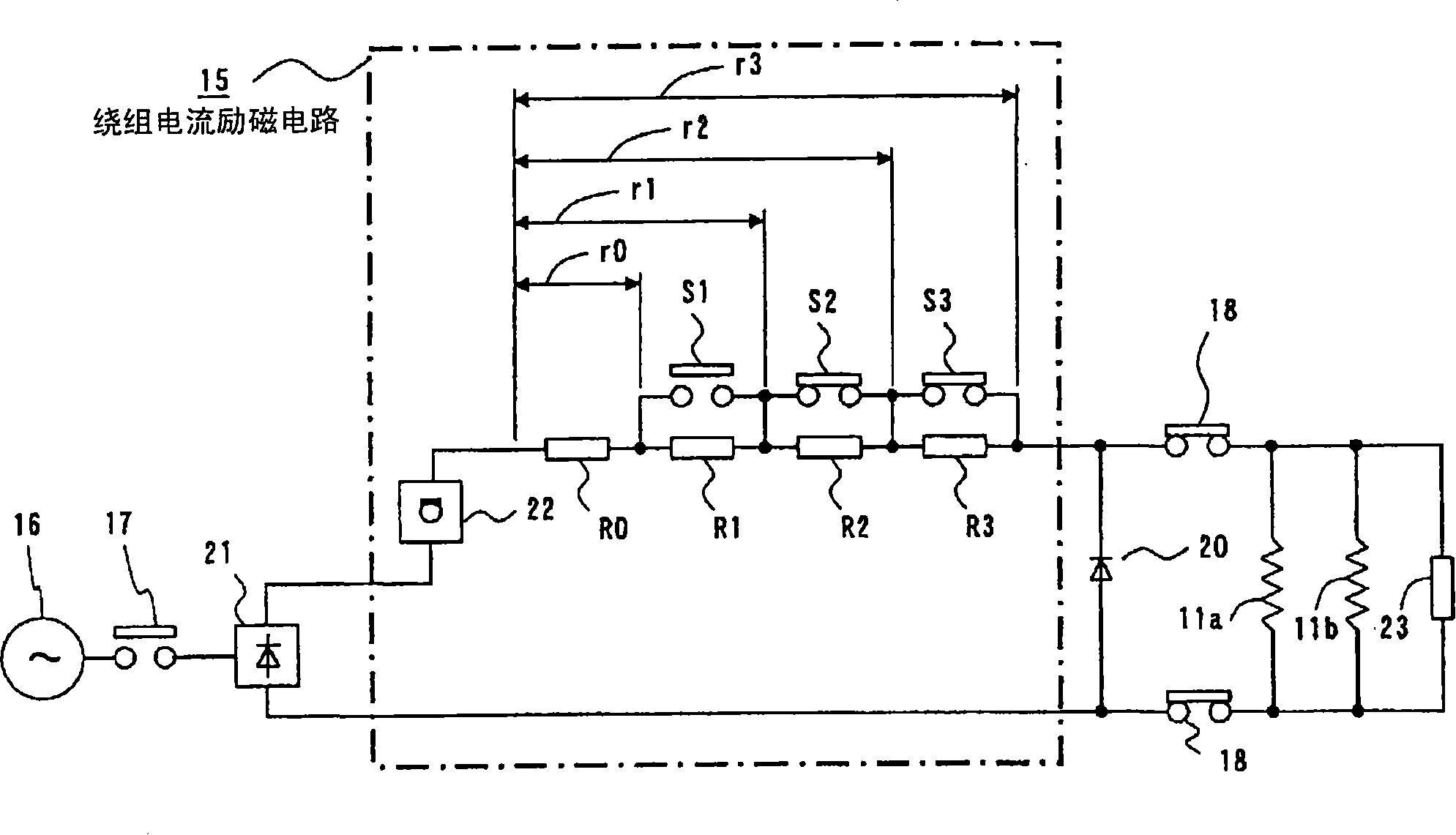

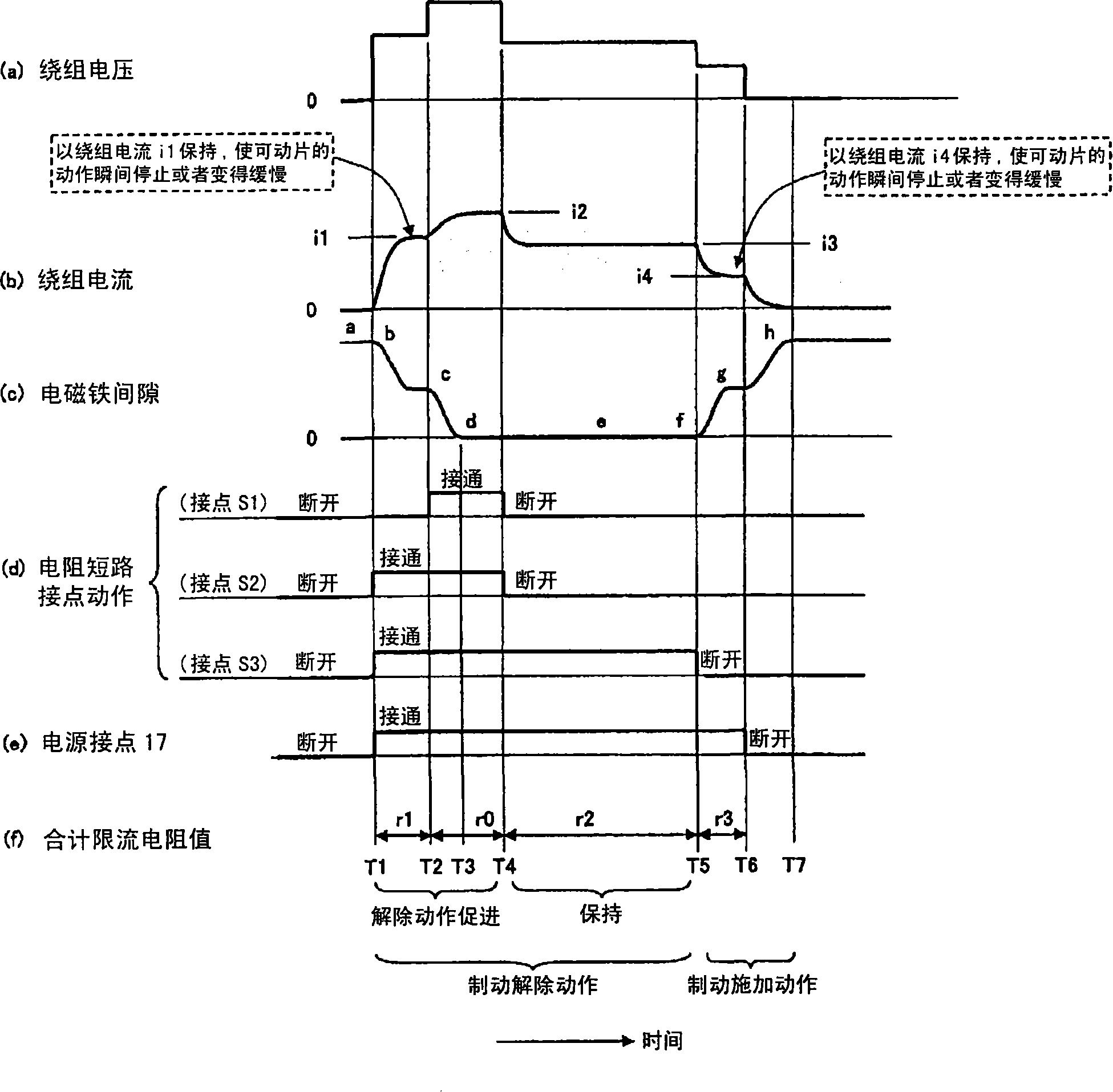

[0138] Figure 1 to Figure 4 One embodiment of the brake control device for elevators according to the present invention is shown. figure 1 It is the overall structure diagram of the brake control device for elevators, figure 2 Yes figure 1 The excitation circuit of the electromagnetic winding, image 3 is a timing chart showing the brake operation, Figure 4 Indicates the relationship between the winding current and the electromagnet gap, especially the image 3 The holding position of the winding current when the brake is released and when the brake is applied. Figure 5 to Figure 7 It is an illustration diagram of the winding voltage and current pattern when the brake is released or when the brake is applied.

[0139] exist figure 1 Among them, 1 represents the sheave of the hoisting machine, and the elevator car 3 is suspended on one side of the main rope 2 woun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com