Rapid pressure filter

A filter press, fast technology, applied in filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of increased weight and manufacturing cost of the whole machine, poor uniformity of the filter chamber feeding, unreasonable force on the rack, etc. , to shorten the unloading time, improve the speed and efficiency of the pulling plate, and shorten the filtration time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

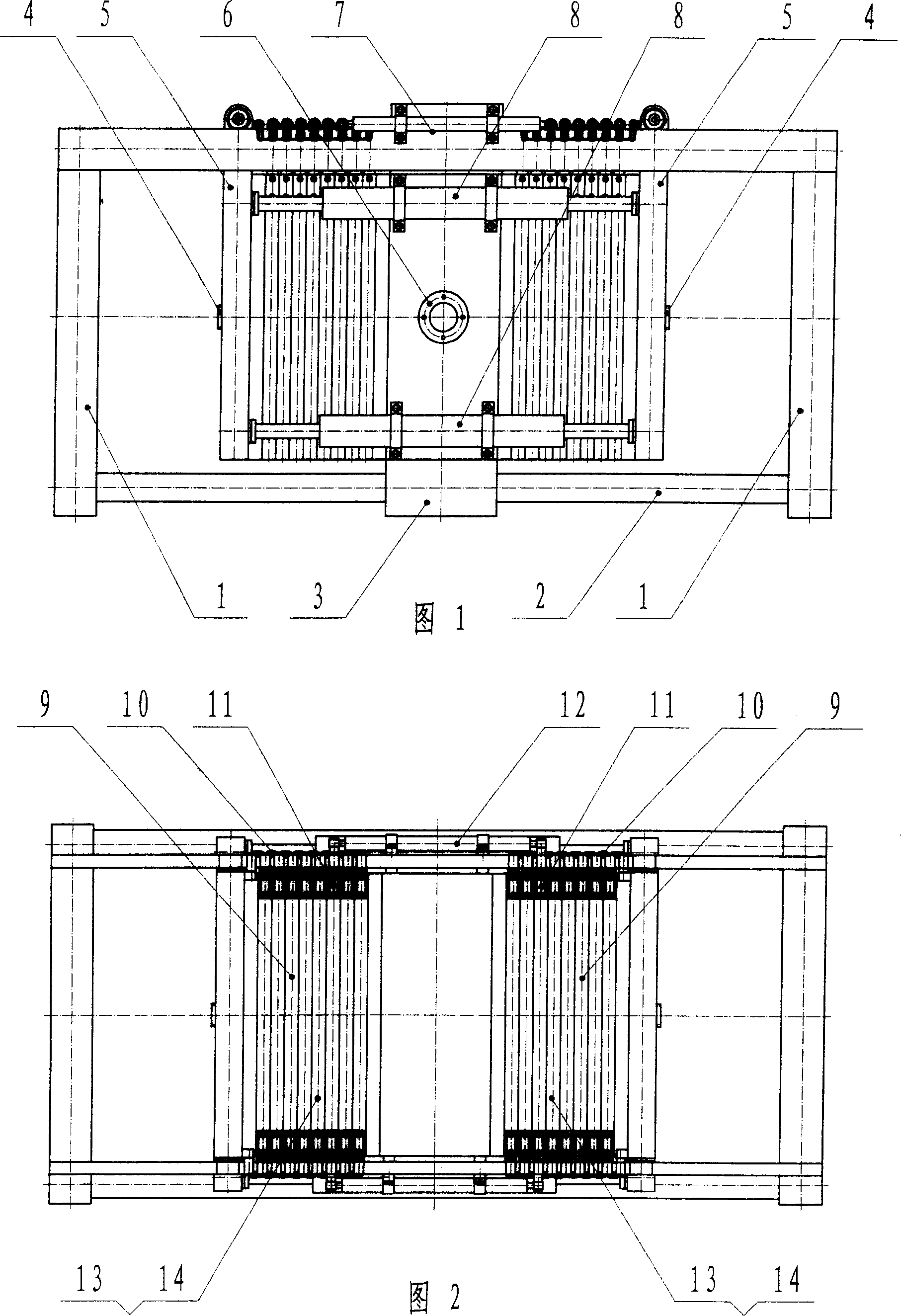

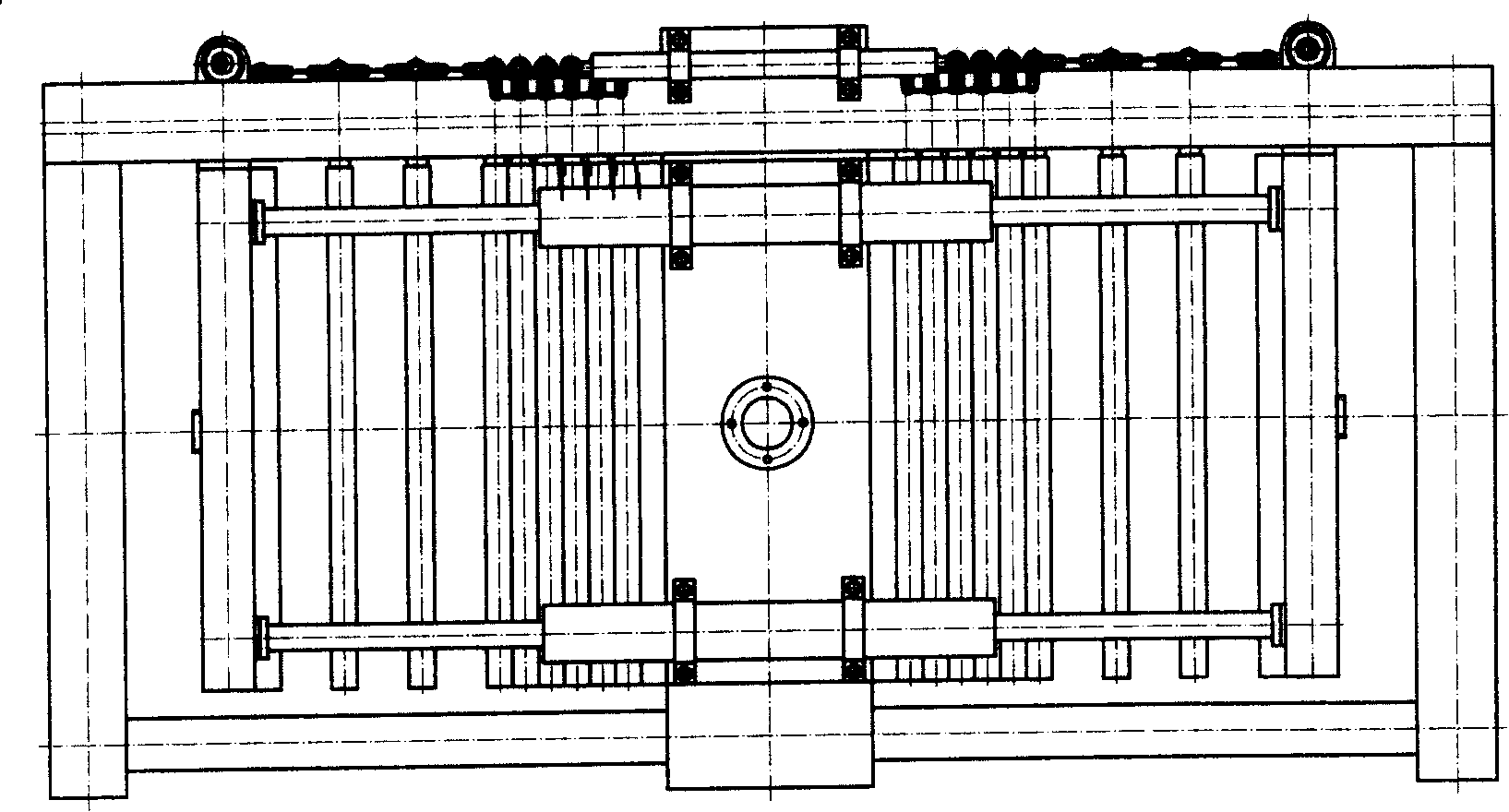

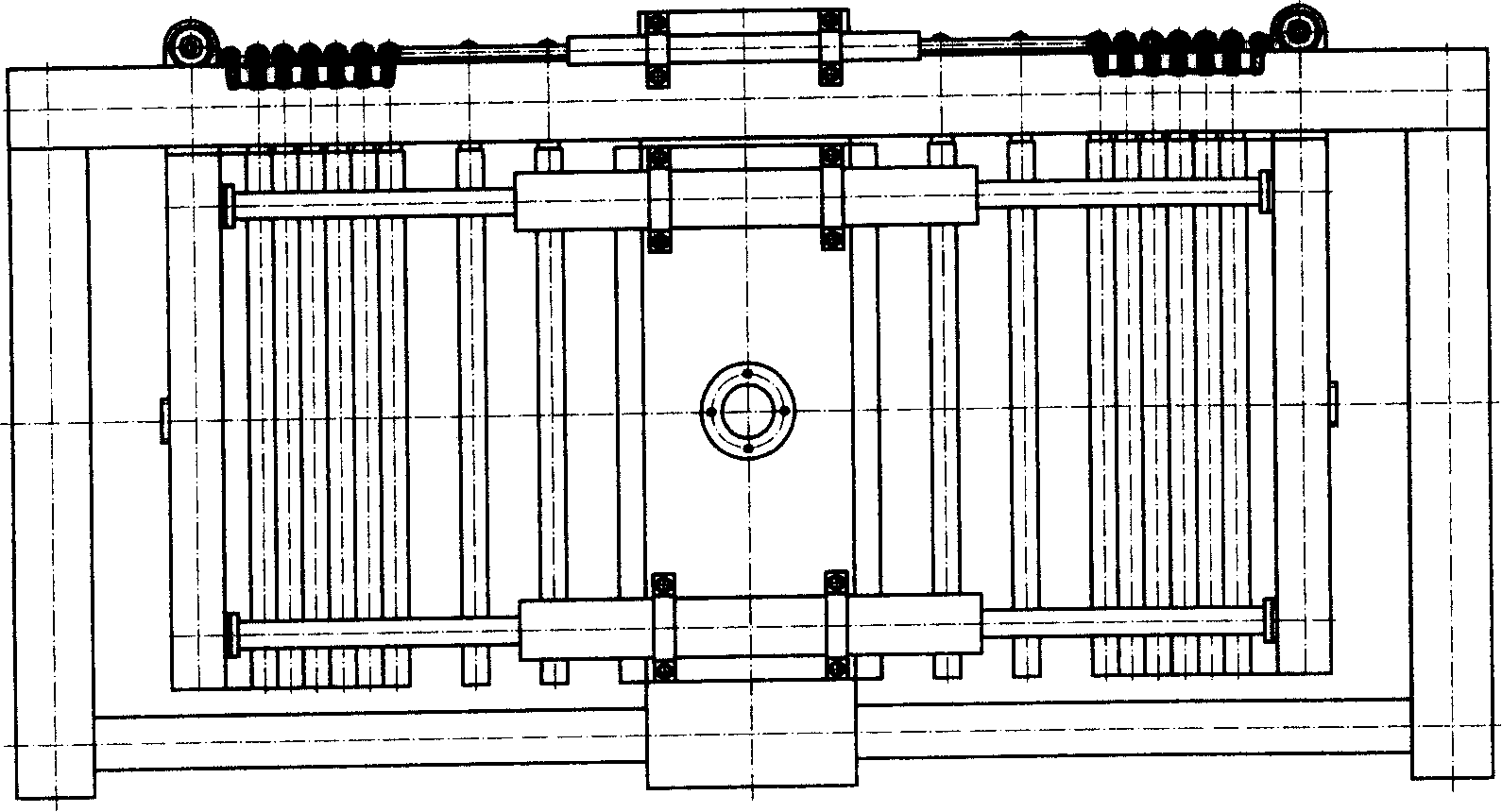

[0017] In Fig. 1, the present invention comprises frame, two filter units, two pressing plates 5, tensioning device and pull plate device, and frame is a frame structure frame symmetrical with frame middle plate 3, and frame The filter unit and the pressing plate 5 are arranged symmetrically in turn on both sides of the middle plate 3. The tensioning device and the pulling plate device are installed in the middle of the frame. The compression plates 5 at both ends of the filter unit on both sides of the plate 3 are hinged, and the filter unit is compressed by a tensioning method that simultaneously symmetrically tightens the compression plates 5 at both ends. The double piston rod discharge hydraulic cylinder in the plate pulling device is a double pull A compact and fast filter press, which includes a frame, two filter units, two compression plates 4, a tensioning device and a plate pulling device, the piston rods at both ends are respectively connected to the filter plates 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com