Conductive asphalt concrete resistance test method

A technology for conducting asphalt and resistance testing, applied in the field of material science and engineering, can solve the problems of inability to continue to use testing methods, limited popularization and application, good engineering simulation, etc., and achieves the effect of consistent compactness, good simulation, and simple electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A resistance testing method of conductive asphalt concrete, it comprises the steps:

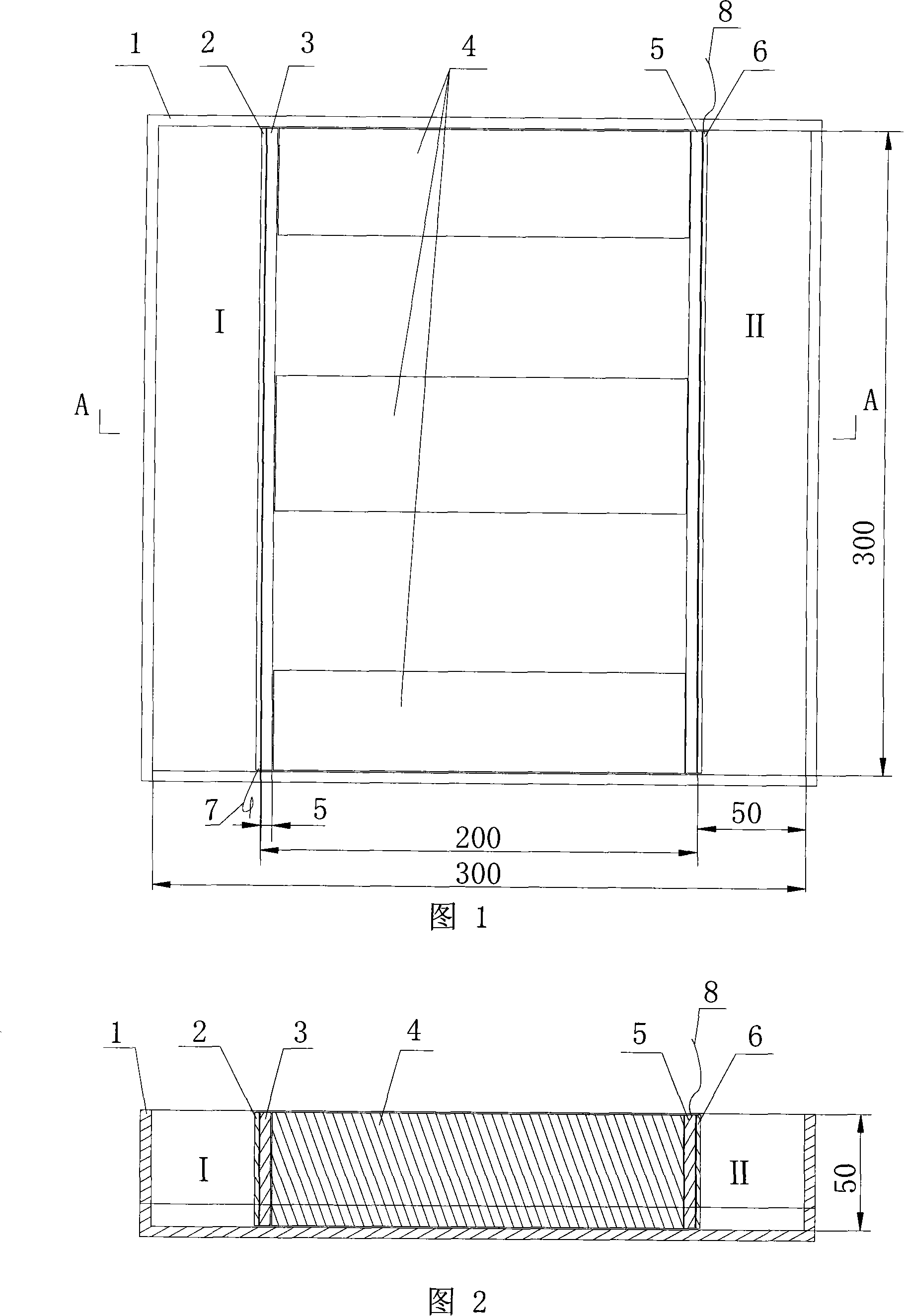

[0024] 1) Preparation of the test device: as shown in Fig. 1 and Fig. 2, the test mold 1, the first electrode 2, the first steel partition 3, the support block 4, the second steel partition 5, and the second electrode 6 , the first lead wire 7, the second lead wire 8, and the resistance measuring instrument (such as a multimeter) constitute a test device; the first electrode 2, the first steel partition plate 3, the support block 4, the second steel partition plate 5, the second The electrodes 6 are put into the cavity of the test mold 1 respectively, and the support block 4 is located between the first steel separator 3 and the second steel separator 5, and is respectively connected to the right side of the first steel separator 3, The left side of the second steel partition 5 is in contact, the front side, rear side and bottom side of the first steel partition 3 are in contact with t...

Embodiment 2

[0035] A resistance testing method of conductive asphalt concrete, it comprises the steps:

[0036] 1) Preparation of the test device: by the test mold 1, the first electrode 2, the first steel partition 3, the support block 4, the second steel partition 5, the second electrode 6, the first wire 7, the second wire 8. A resistance measuring instrument (such as a multimeter) constitutes a test device; put the first electrode 2, the first steel partition 3, the support block 4, the second steel partition 5, and the second electrode 6 into the test mold 1 respectively. In the cavity, the support block 4 is located between the first steel partition 3 and the second steel partition 5, and is connected to the right side of the first steel partition 3 and the left side of the second steel partition 5 respectively. The sides are in contact, the front side, rear side and bottom side of the first steel partition 3 are in contact with the test mold 1 respectively, and the front side, rear...

Embodiment 3

[0043] A resistance testing method of conductive asphalt concrete, it comprises the steps:

[0044] 1) Preparation of the test device: by the test mold 1, the first electrode 2, the first steel partition 3, the support block 4, the second steel partition 5, the second electrode 6, the first wire 7, the second wire 8. A resistance measuring instrument (such as a multimeter) constitutes a test device; put the first electrode 2, the first steel partition 3, the support block 4, the second steel partition 5, and the second electrode 6 into the test mold 1 respectively. In the cavity, the support block 4 is located between the first steel partition 3 and the second steel partition 5, and is connected to the right side of the first steel partition 3 and the left side of the second steel partition 5 respectively. The sides are in contact, the front side, rear side and bottom side of the first steel partition 3 are in contact with the test mold 1 respectively, and the front side, rear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com