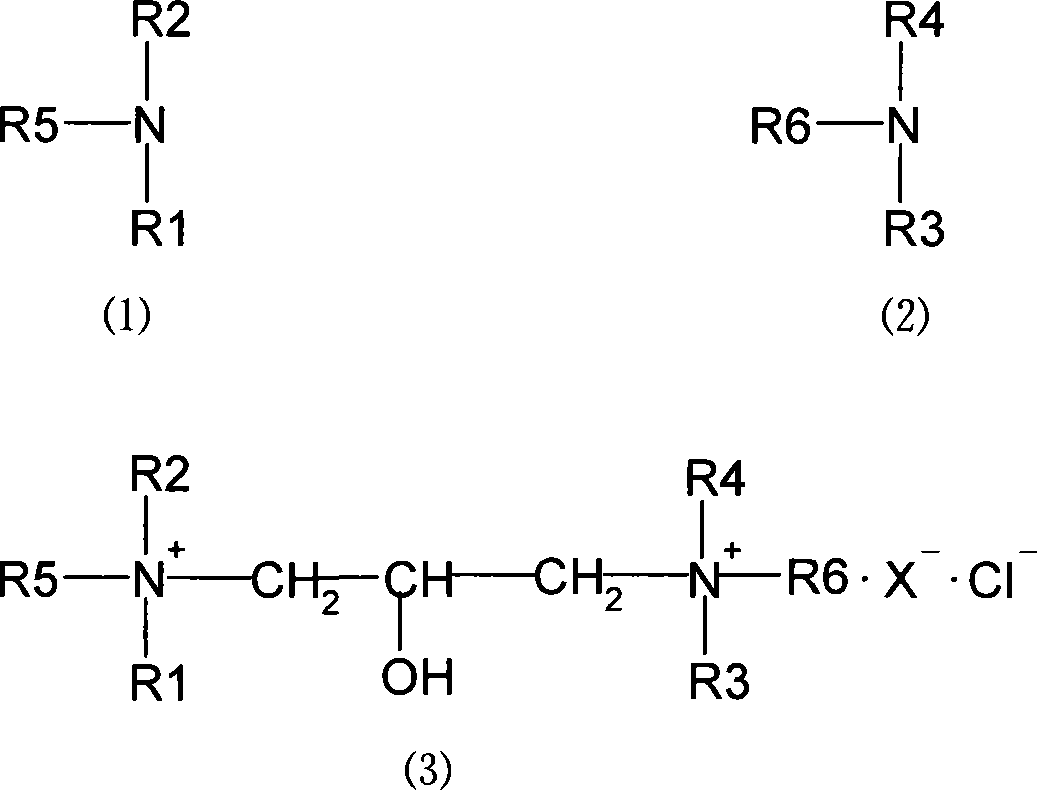

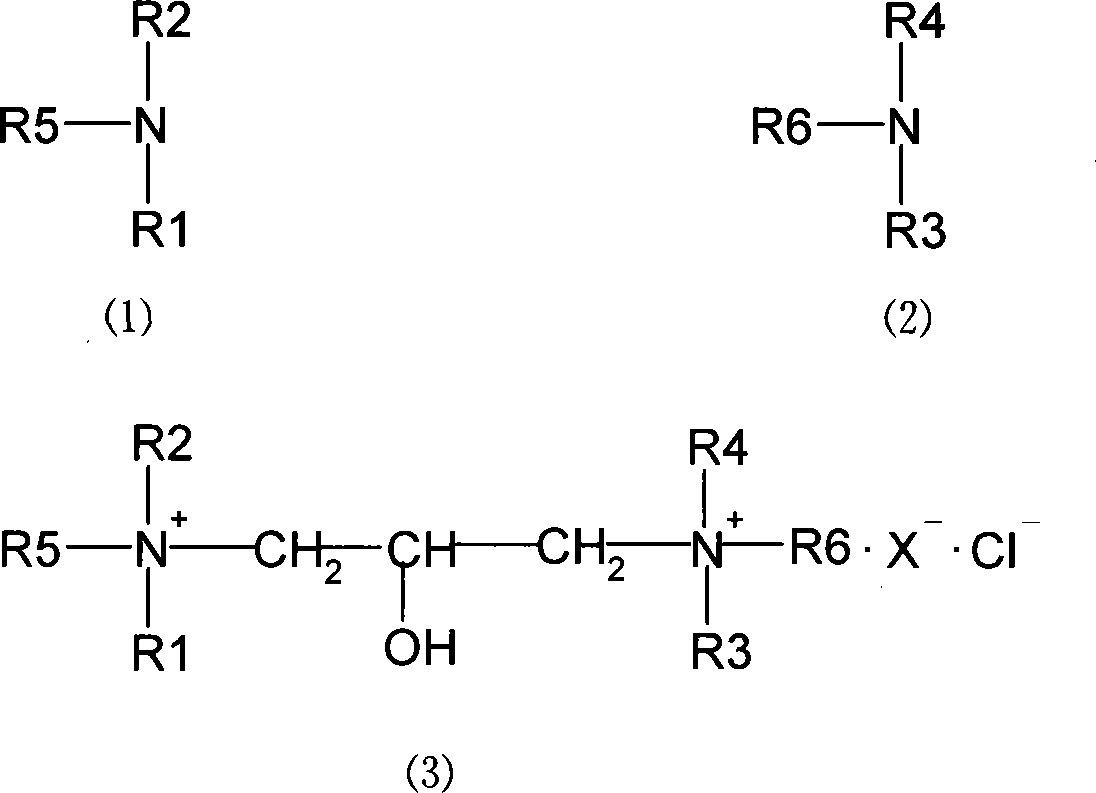

Method for preparing hydroxypropyl diquaternary ammonium salt

A technology of diquaternary ammonium salt and hydroxypropyl, which is applied in the field of preparation of surfactant——hydroxypropyl diquaternary ammonium salt, which can solve problems such as inability to produce, high production cost, cumbersome operation, etc., and achieve easy operation and waste-free Few, Versatile Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Add 203g of dodecyl dimethyl tertiary amine and 80g of ethanol into a 500ml reactor, start stirring and reflux, replace with nitrogen three times, add 84.4g of 20% hydrochloric acid dropwise, control the dropping temperature not greater than 60°C, and finish the dropping Then heat up to 50°C, start adding 46.26g of epichlorohydrin dropwise, cool with a water bath, control the temperature of the material to not exceed 60°C, keep the temperature at 50-85°C for 1 hour after dropping, and slowly raise the temperature to reflux (80-90°C) , constant temperature for 8 hours, lower the temperature to below 60°C and add 30g of ethanol, cool to below 40°C and discharge the material for analysis. Obtained 433.7g light yellow transparent liquid, measured quaternary ammonium compound active matter content 59.5%, free amine 0.7%, calculated yield 98.5%.

[0016] Take 500 g of the above light yellow liquid, add 150 g of acetone while stirring, filter to remove the solvent, and dry to ...

Embodiment 2

[0018] Add 101.5g of dodecyl dimethyl tertiary amine and 80g of ethanol into a 500ml reactor, start stirring and reflux, replace with nitrogen three times, drop in 84.4g of 20% hydrochloric acid, control the dropping temperature not more than 60°C, drop After the completion, the temperature was raised to 50°C, and 46.26g of epichlorohydrin was added dropwise, cooled in a water bath, and the temperature of the material was controlled not to exceed 60°C. Dialkyl dimethyl tertiary amine, slowly heat up to reflux (80-90°C), keep the temperature constant for 8 hours, cool down to below 60°C, add 30g of ethanol, cool down to below 40°C, and discharge for analysis. 455.0 g of light yellow transparent liquid was obtained, the content of quaternary ammonium compound active matter was 56.02%, the free amine was 0.83%, and the calculated yield was 98.1%.

Embodiment 3

[0020] Add 229.39g of tetradecyl dimethyl tertiary amine and 80g of isopropanol into a 500ml reactor, start stirring and reflux, replace with nitrogen three times, add 88g of 20% hydrochloric acid dropwise, and control the dropping temperature not to exceed 60°C. After dropping, the temperature was raised to 50°C, and 46.26g of epichlorohydrin was added dropwise, cooled in a water bath, and the temperature of the material was controlled not to exceed 60°C. ℃), keep the temperature for 12 hours, cool down to below 60°C and add 20g of ethanol, cool down to below 40°C and discharge for analysis. A light yellow transparent liquid was obtained, the content of the active substance of the quaternary ammonium compound was measured to be 56.7%, the free amine was 0.88%, and the calculated yield was 96.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com