Method for processing high quality tea and its key working procedure special purpose equipment

A processing method and high-quality technology, applied in the field of key special processing equipment, tea processing, tea mechanical processing, can solve the problem of reducing content and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The high-quality tea processing method of the present embodiment comprises the following steps:

[0022] 1) Microwave de-enzyming——send fresh tea leaves from the feeding port of the microwave de-enzyming machine into the de-enzyming machine for de-enzyming, keeping the temperature at 85°C for 2.5 minutes;

[0023] 2) Urgent——The tea leaves after being greened by the microwave greening machine are immediately cooled to a temperature of 4°C by the quenching machine for 60 seconds, and the holding time is 1 minute;

[0024] 3) Flattening - the tea leaves after being quenched by the quenching machine are flattened and shaped by the flattening machine, and the temperature is kept at 60°C for 2 minutes;

[0025] 4) Drying—the tea leaves formed by the flattening machine are dried and dehydrated by the dryer, and the temperature is kept at 55° C. for 55 minutes.

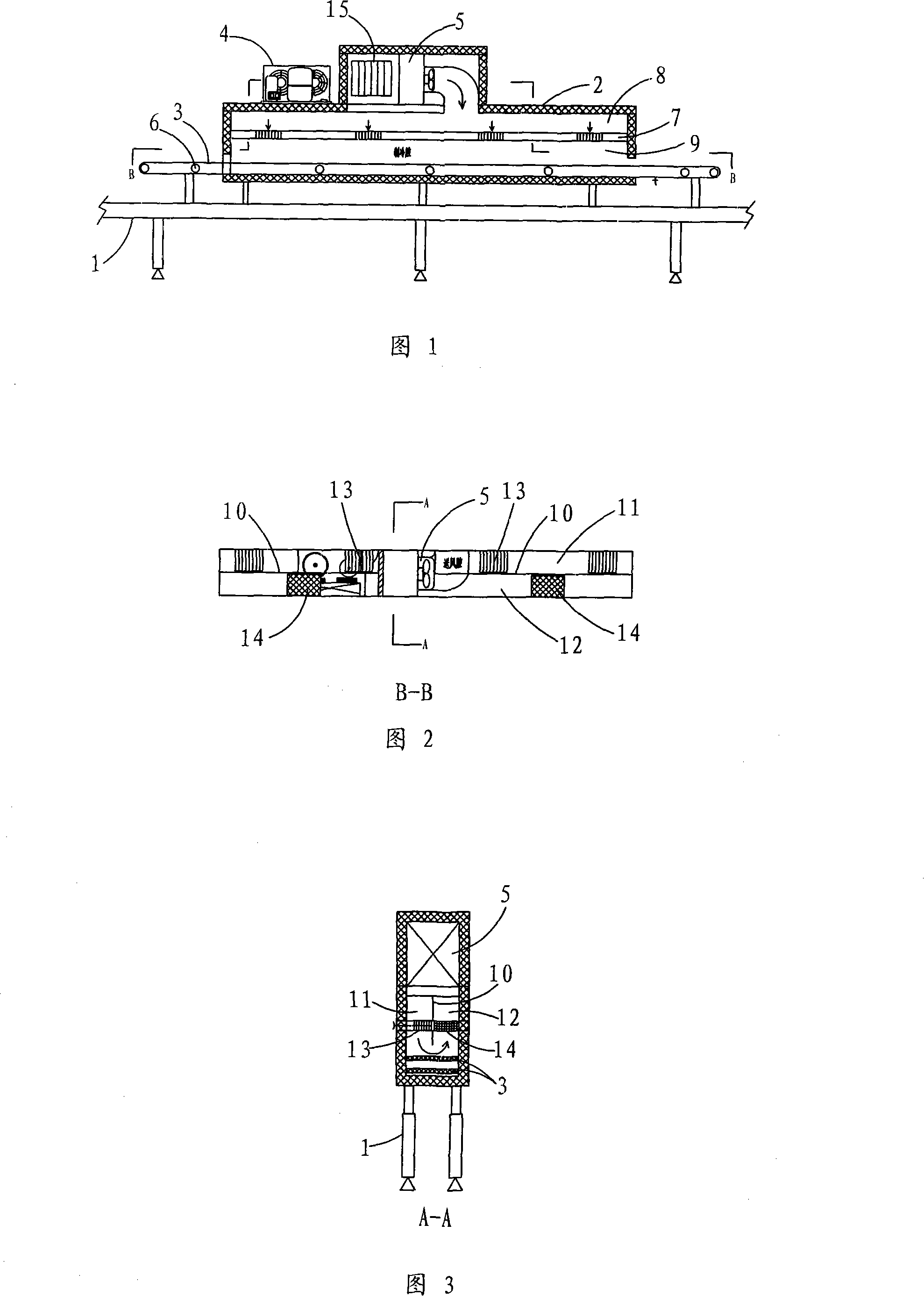

[0026] The special equipment for the key process of this embodiment is a quenching machine. As shown in Figure 1, ...

Embodiment 2

[0033] The high-quality tea processing method of the present embodiment is basically the same as embodiment one, the difference is:

[0034] 1) The finishing temperature of the step is kept at 95° C., and the time is kept for 2 minutes;

[0035]2) The rapid cooling time of the step is 80 seconds, the temperature is kept at 10° C., and the time is kept for 1.5 minutes;

[0036] In the 3rd) step, the flattening machine is replaced by a rafting machine, the temperature is kept at 70° C., and the time is kept for 30 minutes;

[0037] Step 4) The drying temperature in the step is kept at 60° C., and the drying time is kept for 40 minutes.

[0038] Specifically, when using the special equipment for the key process of this embodiment-the quenching machine to machine the tea leaves, the inlet end of the refrigeration chamber 2 and the outlet end of the microwave greening machine can be closed and connected to each other, and then the conveyor belt The outlet end of 3 is connected wi...

Embodiment 3

[0040] The high-quality tea processing method of the present embodiment is basically the same as embodiment one, the difference is:

[0041] 1) The finishing temperature of the step is kept at 105° C., and the time is kept for 1.2 minutes;

[0042] 2) The rapid cooling time of the step is 65 seconds, the temperature is kept at 17° C., and the time is kept for 2.5 minutes;

[0043] In the 3rd) step, the flattening machine is replaced by a kneading machine, and the temperature during kneading is kept at 65° C., and the time is kept for 35 minutes;

[0044] Step 4) The drying temperature in the step is kept at 70° C. for 30 minutes.

[0045] Specifically, when using the special equipment for the key process of this embodiment-the quenching machine to machine the tea leaves, the inlet end of the refrigeration chamber 2 and the outlet end of the microwave greening machine can be closed and connected to each other, and then the conveyor belt The outlet end of 3 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com