Stack type metal-oxide-metal capacitor structure

A metal capacitor and oxide technology, applied in capacitors, electric solid devices, circuits, etc., can solve the problem of occupying semiconductor area and volume, and achieve the effect of large capacitance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

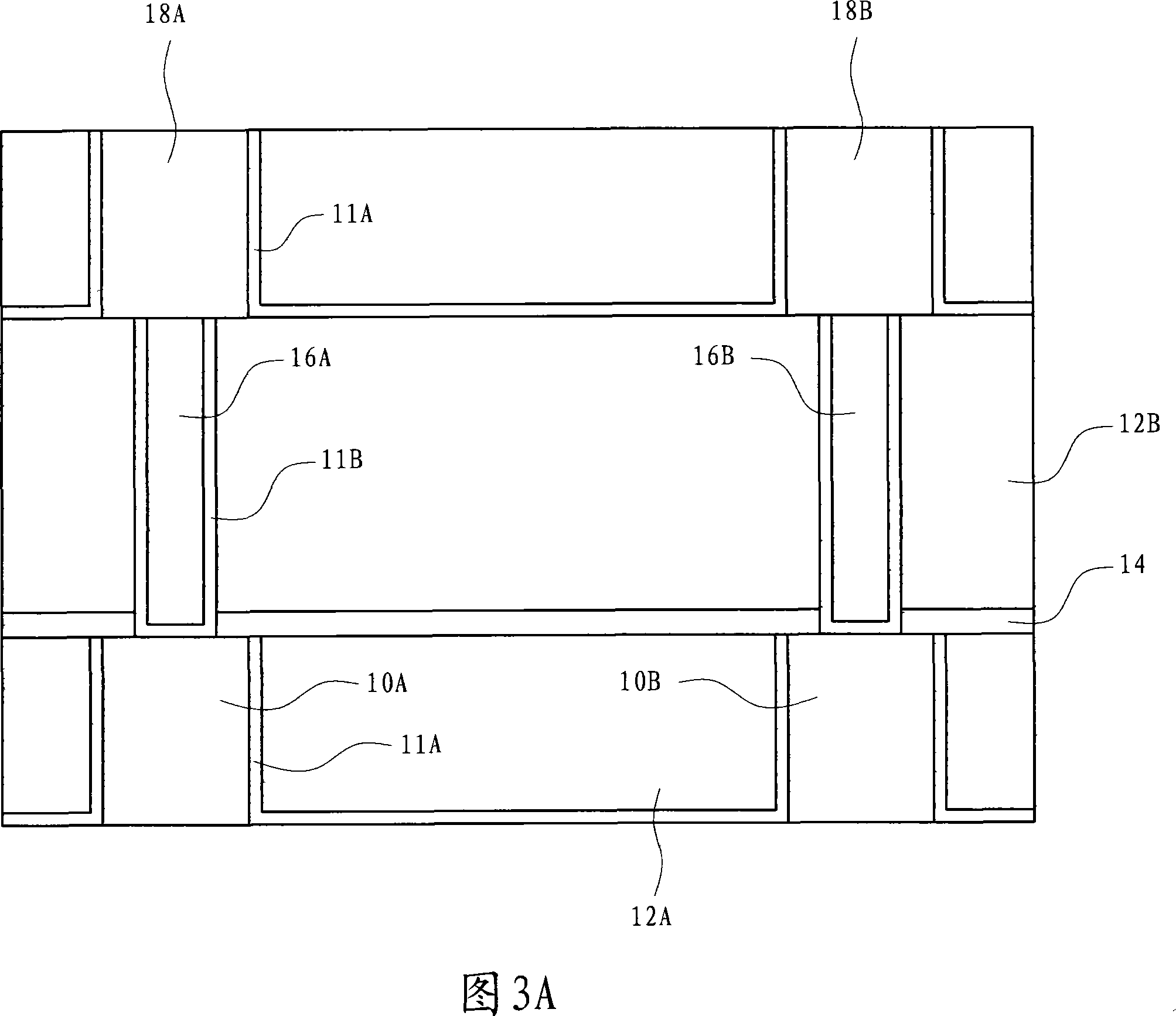

[0048] In order to further explain the technical means and effects that the present invention takes to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, Features and their functions are described in detail below.

[0049] While the metal-oxide-metal capacitor structures and methods of fabrication of the present invention are described with reference to exemplary damascene structures, it will be appreciated that these damascene structures can be fabricated using conventional single or dual damascene processes.

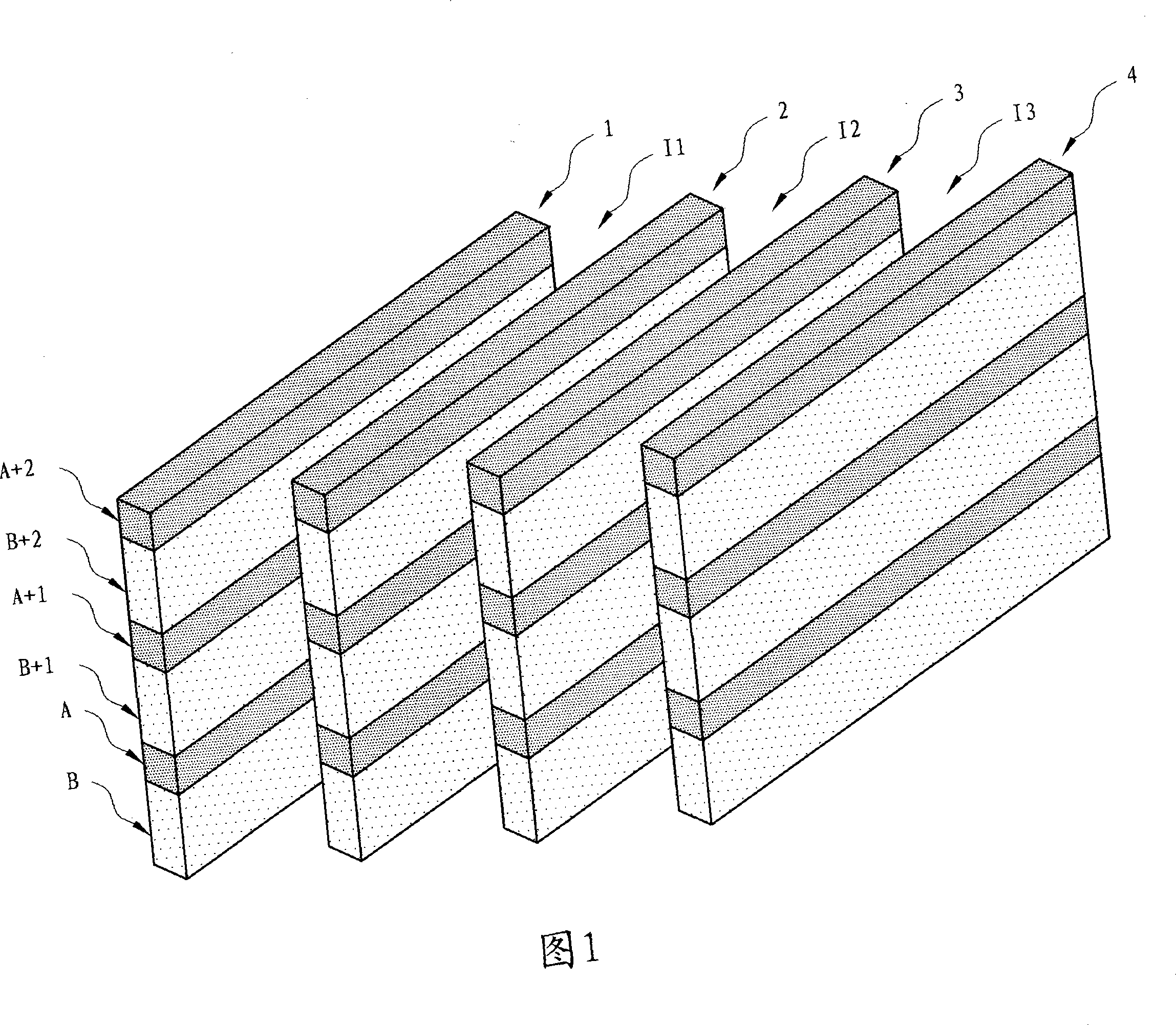

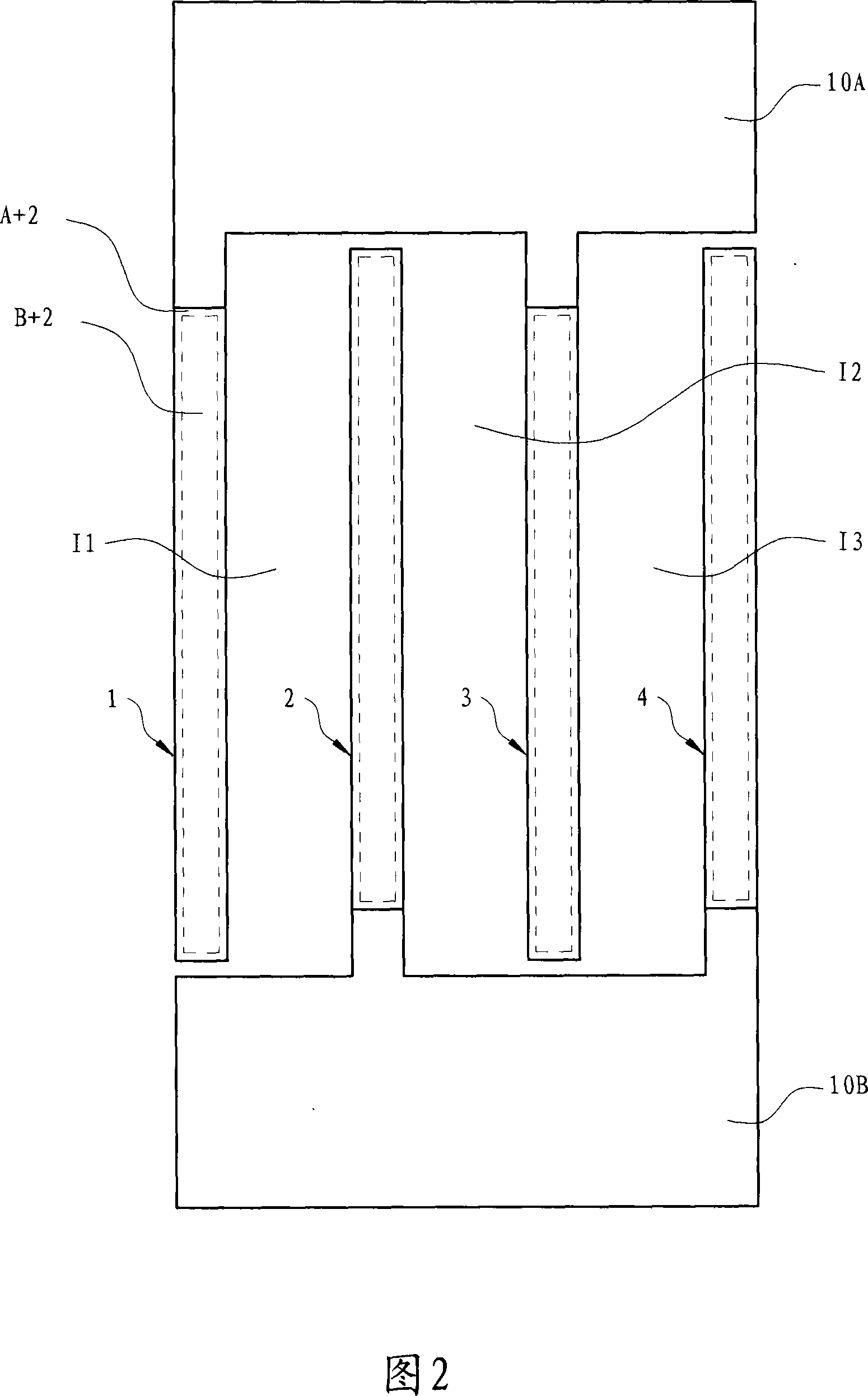

[0050] Please refer to FIG. 1 , which shows a perspective view of an exemplary stacked metallization structure, which only shows the metal part, so as to more properly illustrate the metal-oxide-metal capacitor structure of the present invention. It will be appreciated that one or more capacitor dielectric materials, such as dielectric materials I1, I2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com