Blow molding forming bottle with handle and manufacturing device for the same

A technology of blow molding and manufacturing devices, which is applied to container handles, bottles, and other household appliances, etc., and can solve the problems of troublesome removal of the support plate 108 and the easy removal of the handle 104

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

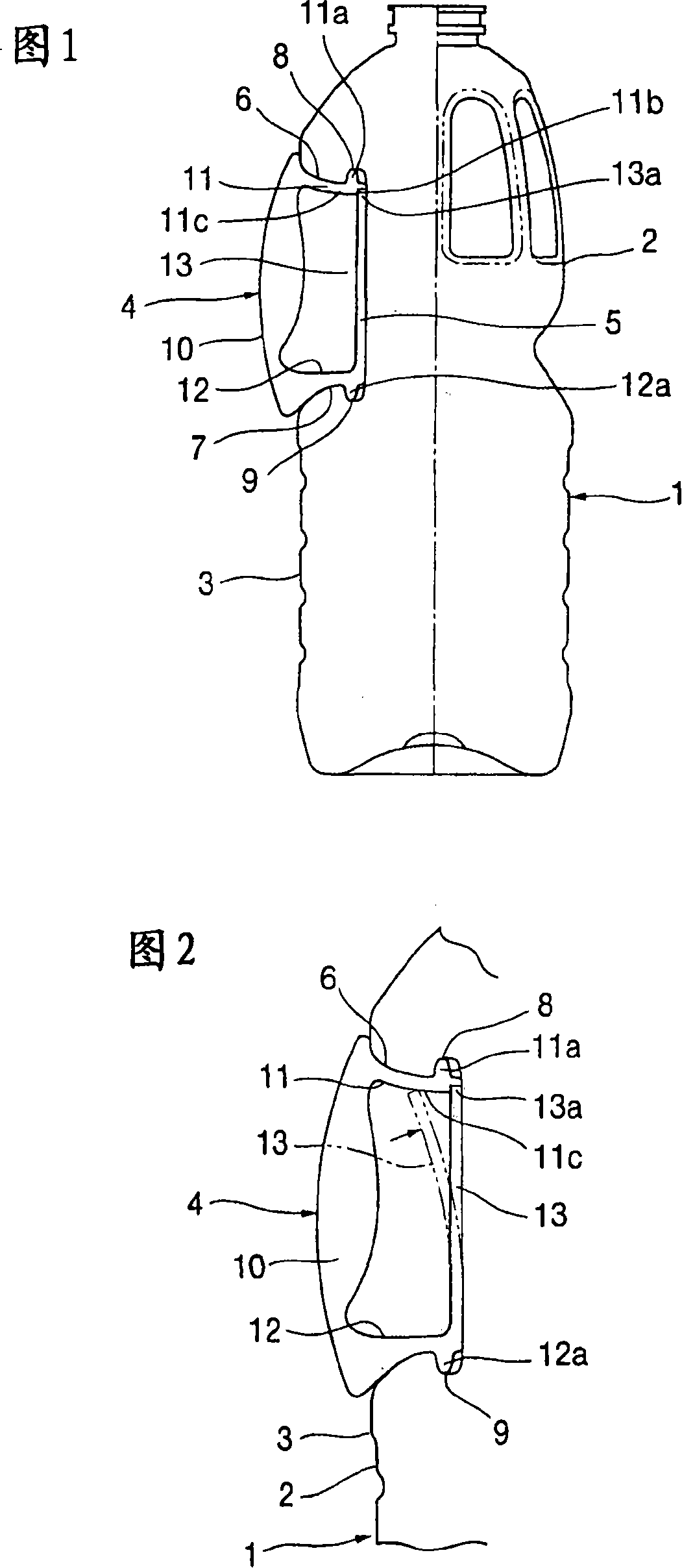

[0038] The present embodiment 1 is a bottle with a handle corresponding to the invention of technical scheme 1. The bottle 1 is a bottle made of polyester resin formed by blow molding, and a handle 4 made of the same polyester is attached to the surface of the trunk portion 3 of the bottle body 2 later.

[0039] The bottle 1 with handle 4 is described in more detail below. In order to install the handle on the surface of the body part 3 of the bottle body 2, a part of the circumference is cut off to form the handle mounting part 5 at a position recessed from the circumference. The opposite positions form bottom-side recesses 8, 9 consisting of pits of predetermined depth and shape.

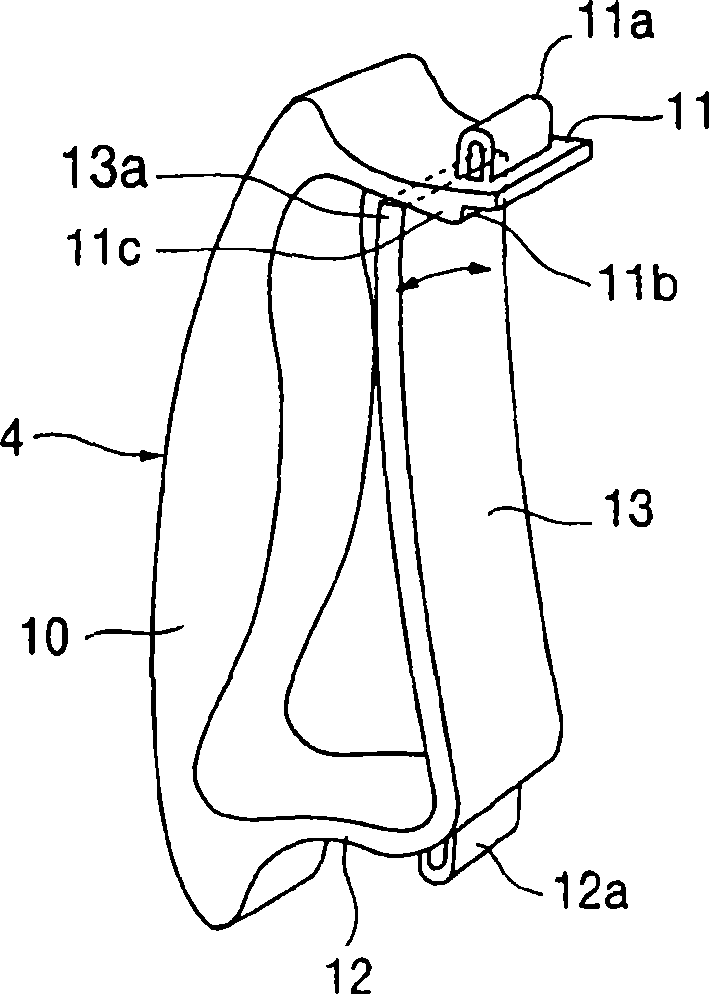

[0040] In handlebar 4 as image 3 As shown, the handle portion 10, the upper arm 11 and the lower arm 12 protruding from the handle portion 10 in the horizontal direction, and the upper and lower bottom side recesses 8, 9 respectively formed on the outside of the front ends of the upper and lower...

Embodiment 2

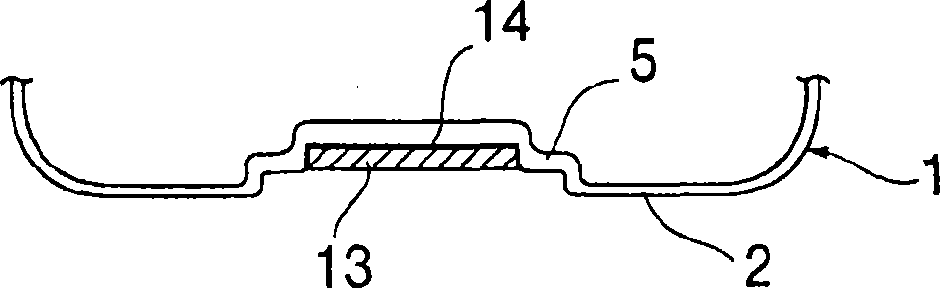

[0044]This embodiment 2 corresponds to the invention described in technical solution 2, such as Figure 4 As shown, on the front of the mounting part 5 corresponding to the support plate 13, a recess 14 is formed to accommodate the support plate 13, and the support plate 13 is accommodated in the recess 14, thereby preventing the support plate 13 from shaking to the left and right and causing the support Power is unstable.

Embodiment 3

[0046] This embodiment 3 corresponds to the invention described in technical solution 3, on the slope 11c formed under the upper arm 11 of the handle 4 as Figure 5 The guide rib 15 is formed as shown, and the upper end portion 13a of the support plate 13 is formed with the notch portion 13b engaged with the guide rib 15, as shown by the arrow from the position of the dashed line 1 in FIG. When the support plate 13 is pressed in by joining 11b, the upper end portion 13a of the support plate 13 is guided without swinging left and right, and the support plate 13 can be joined to a predetermined position in a correct posture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com