Trace heating for oil well viscosity,coagulation reduction and dewaxing

A technology of heat tracing and viscosity reduction, which is used in cleaning appliances, wellbore/well components, isolation devices, etc., can solve the problems of reducing the space for economic benefits, increasing the cost of crude oil production, and yet to see a successful solution. Achieve the effect of improved technical level, low construction cost and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail by means of embodiments in conjunction with the accompanying drawings.

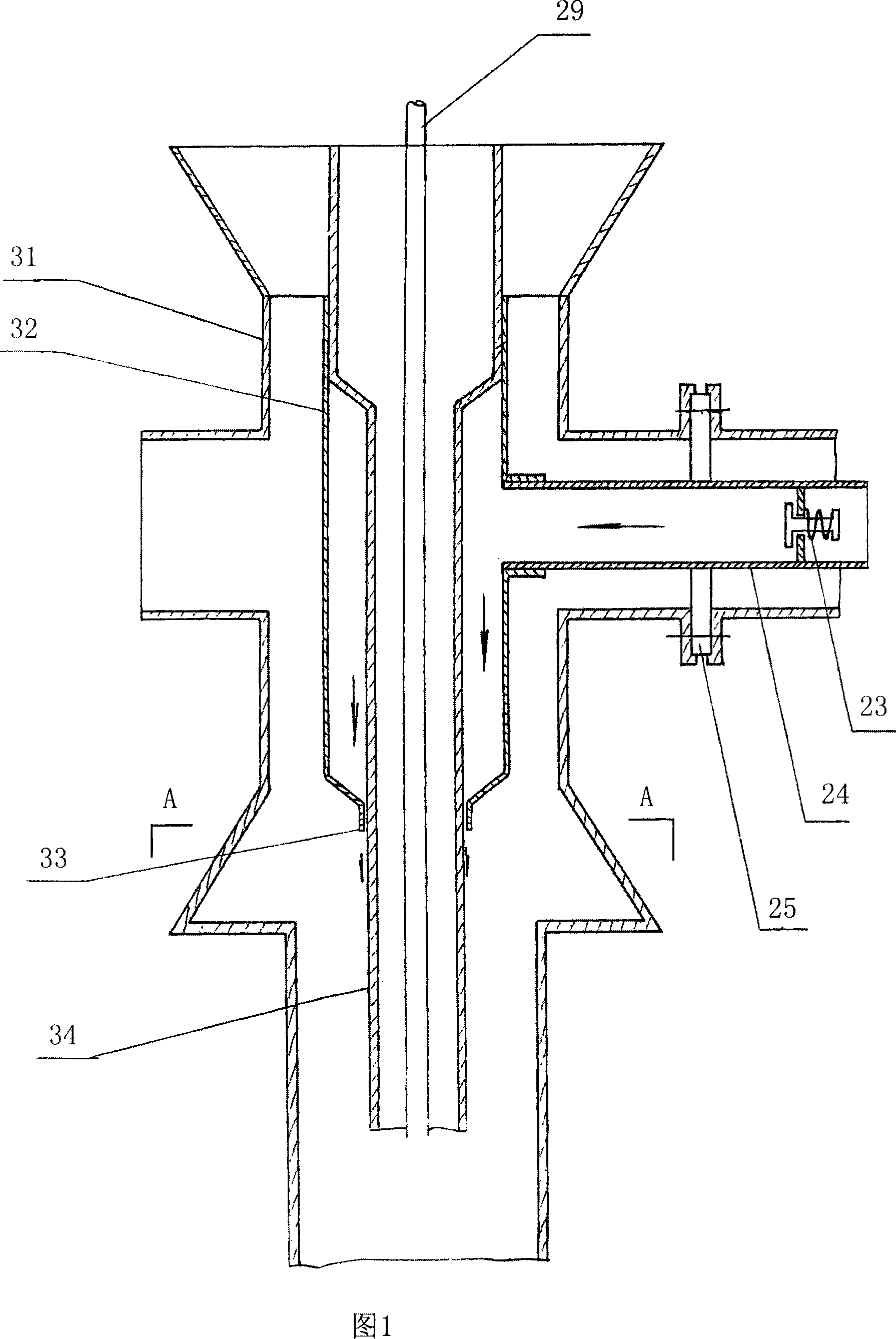

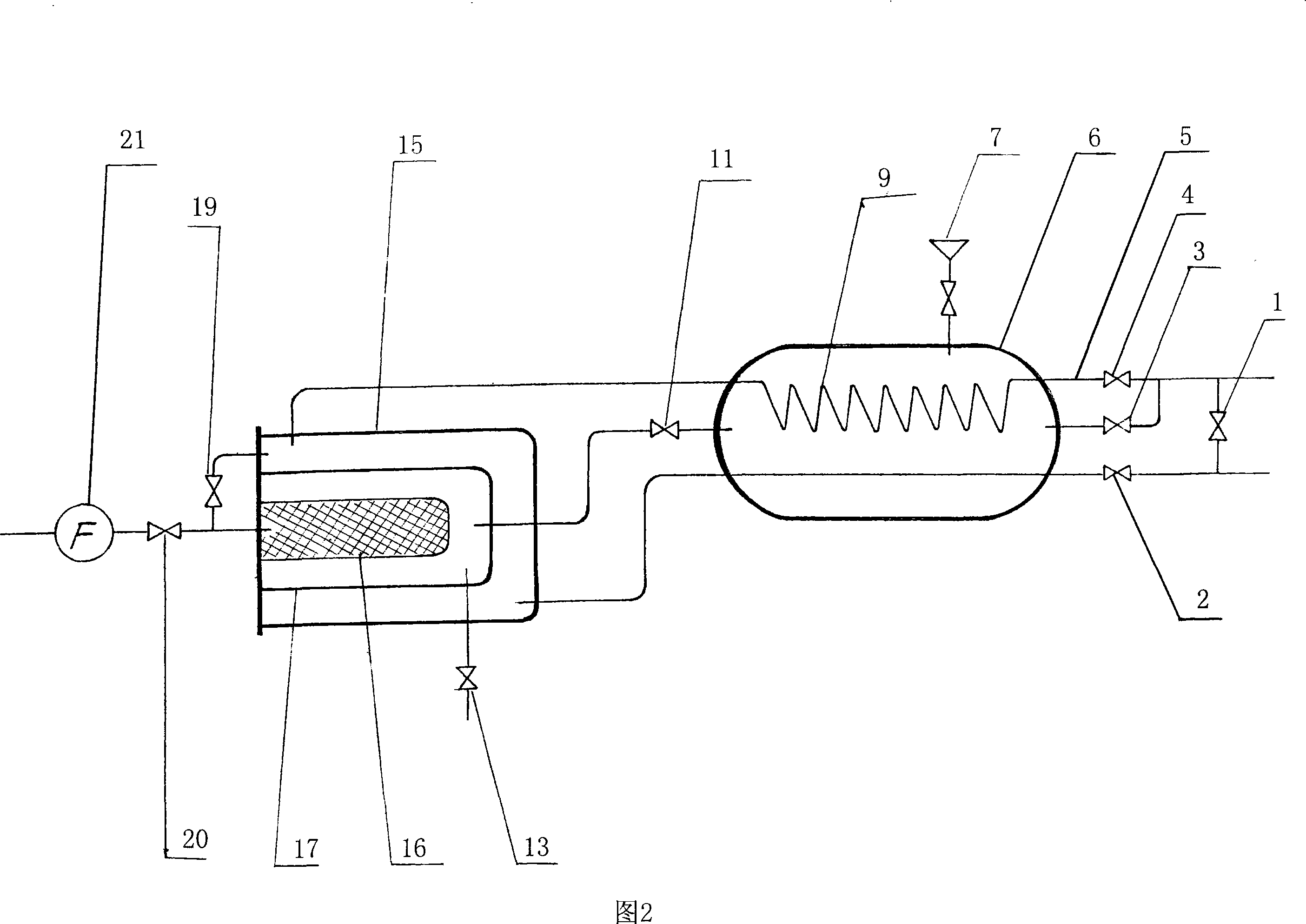

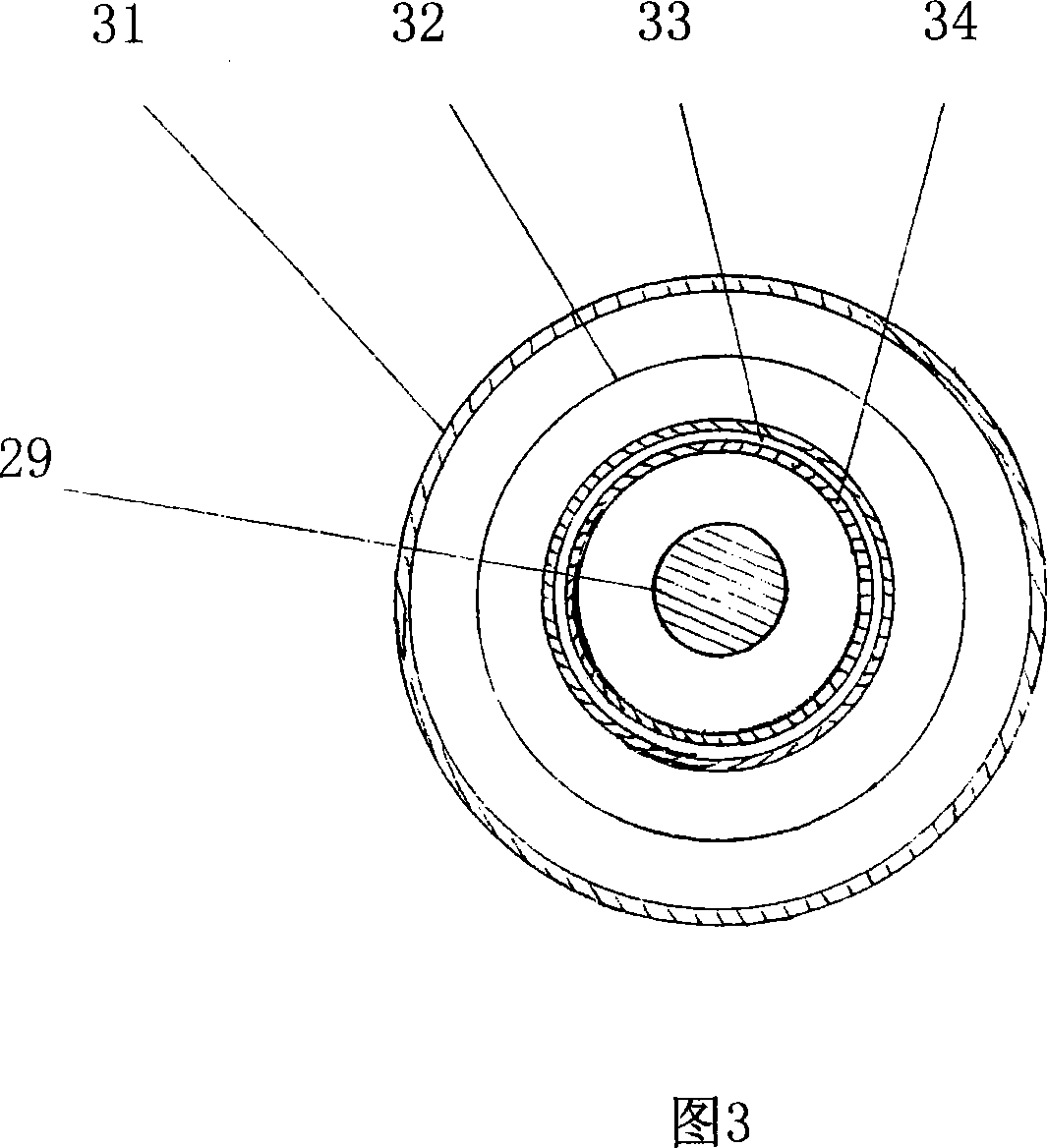

[0019] As shown in Figure 1, the lower end of the buffer 32 penetrates into the main cavity of the large cross 31 and is installed on the upper part of the oil pipe 34, the upper inner wall of the buffer 32 is tightly combined with the upper outer wall of the oil pipe 34 to prevent water from crossing, and the lower end of the water outlet 33 There is a gap between the oil pipe 34 and the outer diameter of the oil pipe 34, and one side is provided with a pipe interface connected to one end of the hot water inlet pipe 24, and the other end of the hot water inlet pipe 24 is provided with a check valve 23, and passes through the flowmeter 21 , the flow control valve 20, the filter 16, the water supply valve 11, the water tank 6 and the water supply valve 3 are connected to the pipeline of the hot water circulation system of the well station, as shown in Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com