Secondary lithium ionic cell and preparation method of cathode pole piece thereof

A lithium-ion battery and negative pole piece technology, which is applied in secondary batteries, electrode manufacturing, active material electrodes, etc., can solve problems such as uneven distribution of coatings, protection of the inner layer, and lack of contact resistance on the surface of the negative pole piece.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

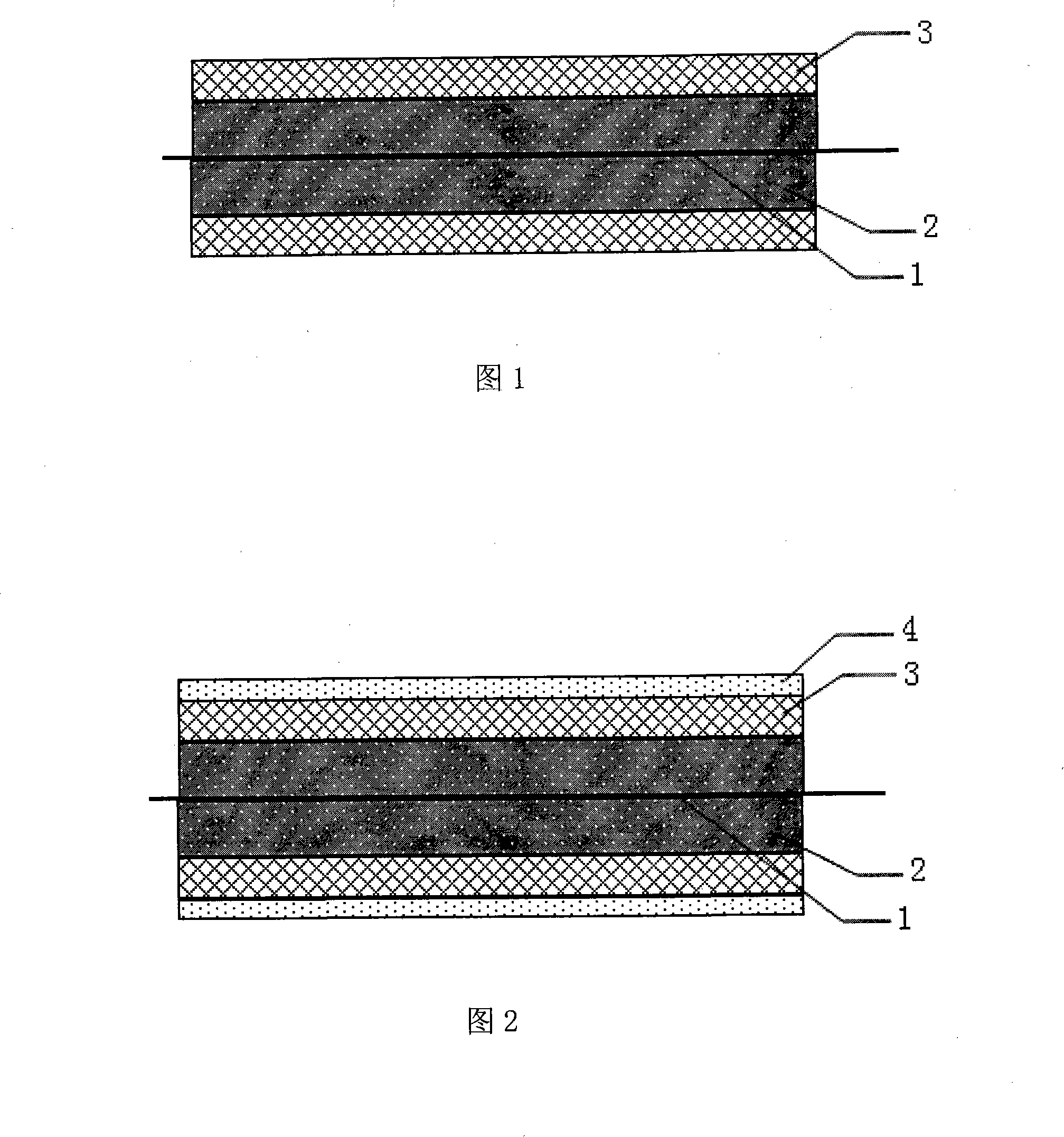

[0016] Referring to Fig. 1, artificial graphite FSNC, conductive carbon Super-P, carboxymethyl cellulose sodium CMC (a kind of thickener), styrene-butadiene rubber SBR (a kind of thickener), according to the ratio A that is 94.5:1.5 : 1.5: 2.5 mixed with deionized water and stirred evenly to obtain negative electrode coating slurry a, during the stirring process, the viscosity was adjusted by deionized water, and then the slurry a was coated on both sides of the negative electrode current collector (copper foil) 1, Form the first diaphragm layer 2 (i.e. the inner diaphragm layer), and after simple cold pressing, a kind of mesophase carbon microsphere graphite MCMB, aluminum oxide Al 2 o 3 , carboxymethyl cellulose sodium CMC (a kind of thickener), styrene-butadiene rubber SBR (a kind of thickener), according to proportion B namely 90.5: 5.5: 1.5: 2.5 is mixed with deionized water and stirred evenly to obtain negative electrode Slurry b was coated and the viscosity was adjuste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com