End accessory structure of combined insulator and manufacturing method thereof

A composite insulator and insulator technology, applied in insulators, suspension/strain insulators, electrical components, etc., can solve the problems of potential safety hazards, poor quality stability, easy to loose, brittle cracks, etc., to improve insulation reliability, reduce Weight, effect for a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

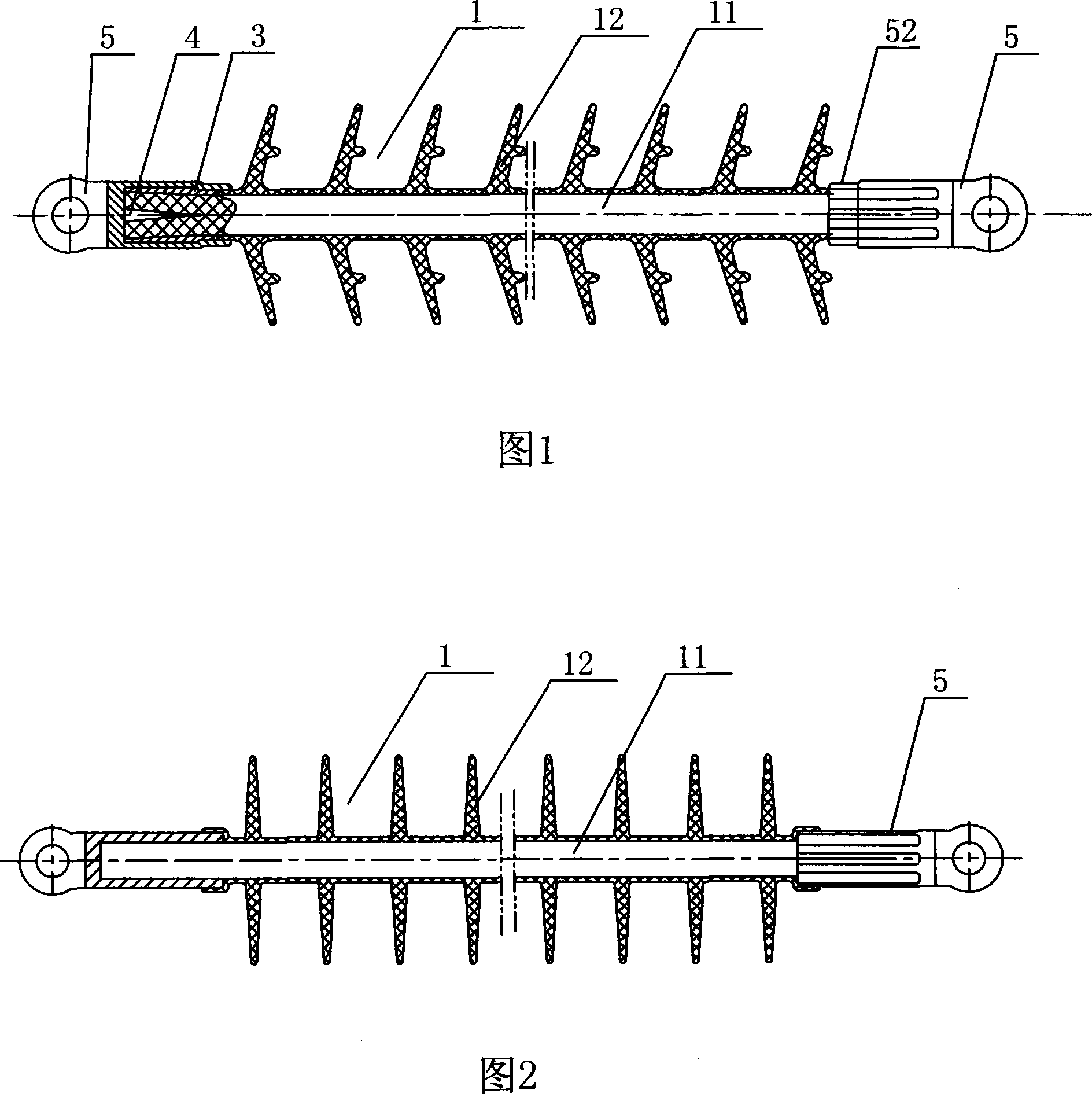

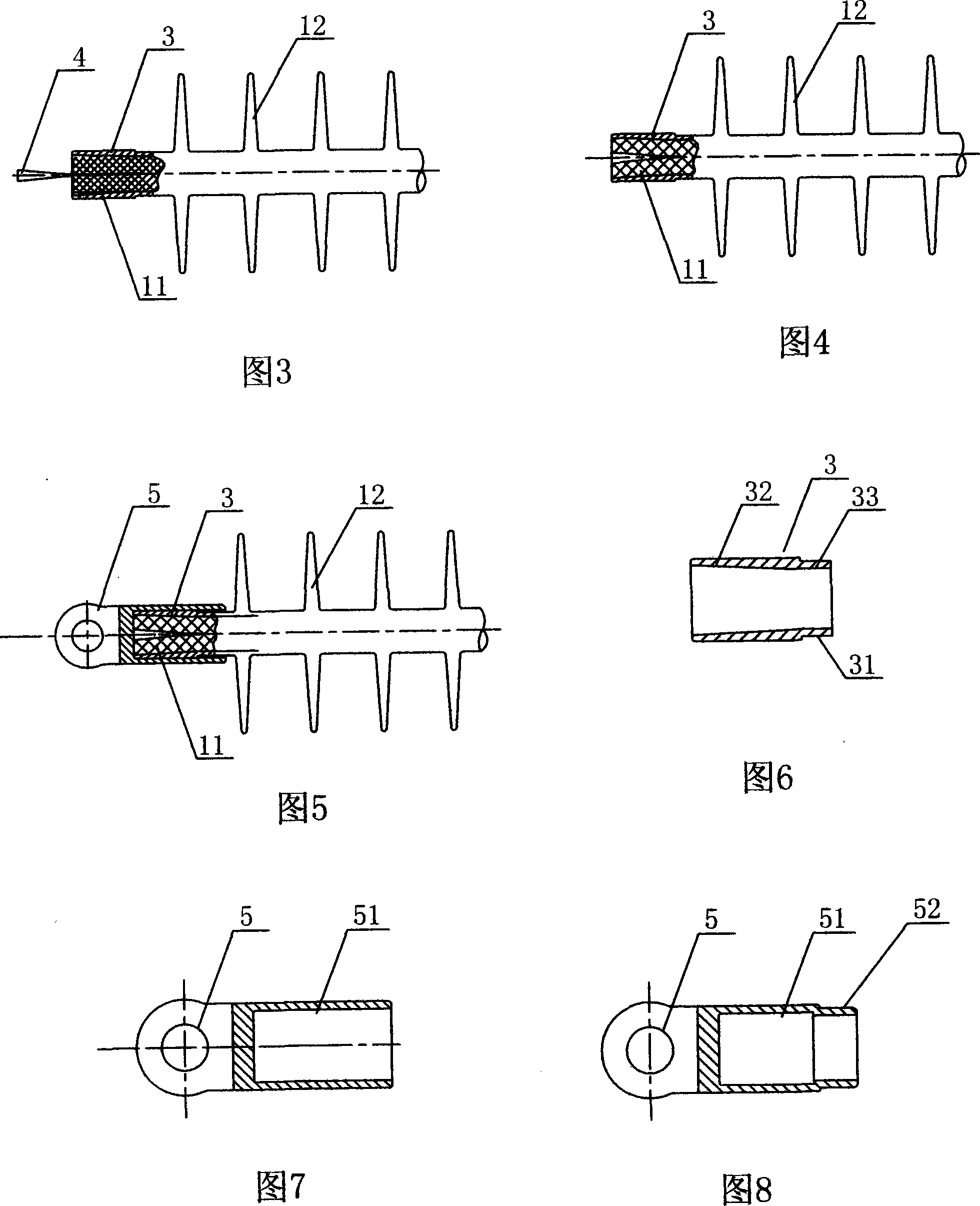

[0025] As shown in Figure 2, it is a traditional insulator end attachment structure.

[0026] As shown in Figure 1, the composite insulator includes a mandrel 11 and a shed shed 12, and the end attachment structure of the composite insulator includes an expansion cone 4, a cone sleeve 3, and a connection accessory 5, wherein: the expansion cone 4 is inserted into the mandrel On the inner surface of both ends of 11 , the taper sleeve 3 is sleeved on the end of the mandrel 11 , and the connecting accessory 5 is sleeved at the interface between the taper sleeve 3 and the umbrella skirt sleeve 12 .

[0027] As shown in Figure 3, the expansion cone 4 includes two parts, one part is a guide cylinder with the diameter of the small hole provided at the end of the mandrel 11, and the other part is a cone whose diameter gradually increases, and the size of the cone is based on Request settings.

[0028] As shown in FIG. 6 , a stop step 31 is provided on the outer circle of the cone sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com