Heat-proof polychloroethylene transparent adhesive tape

A technology of polyvinyl chloride and transparent adhesive tape, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of multiple processing and manufacturing procedures, high equipment costs, waste solvent environmental protection, etc., to avoid waste solvent environmental protection problems, The effect of production speed and environmental protection, simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

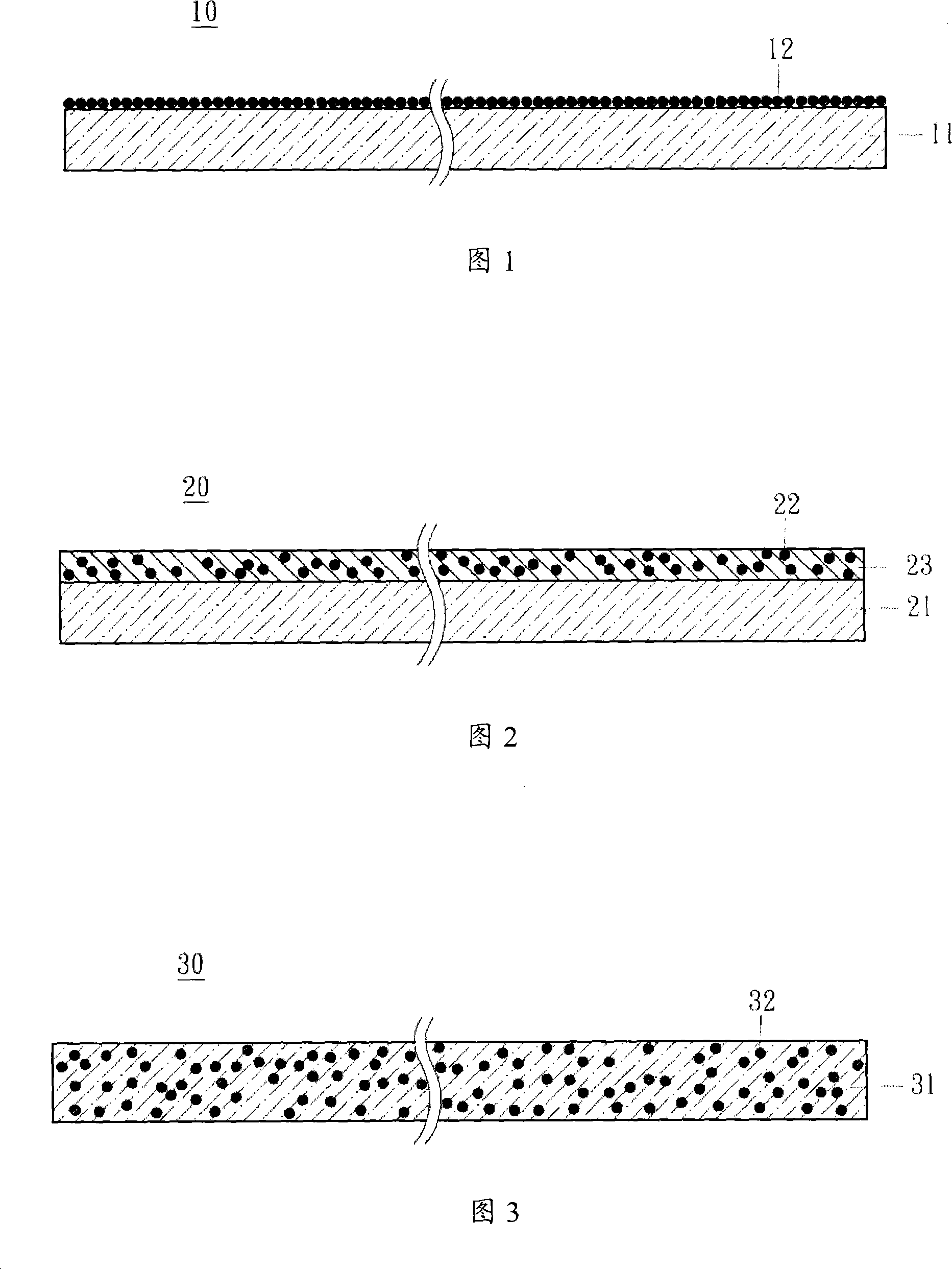

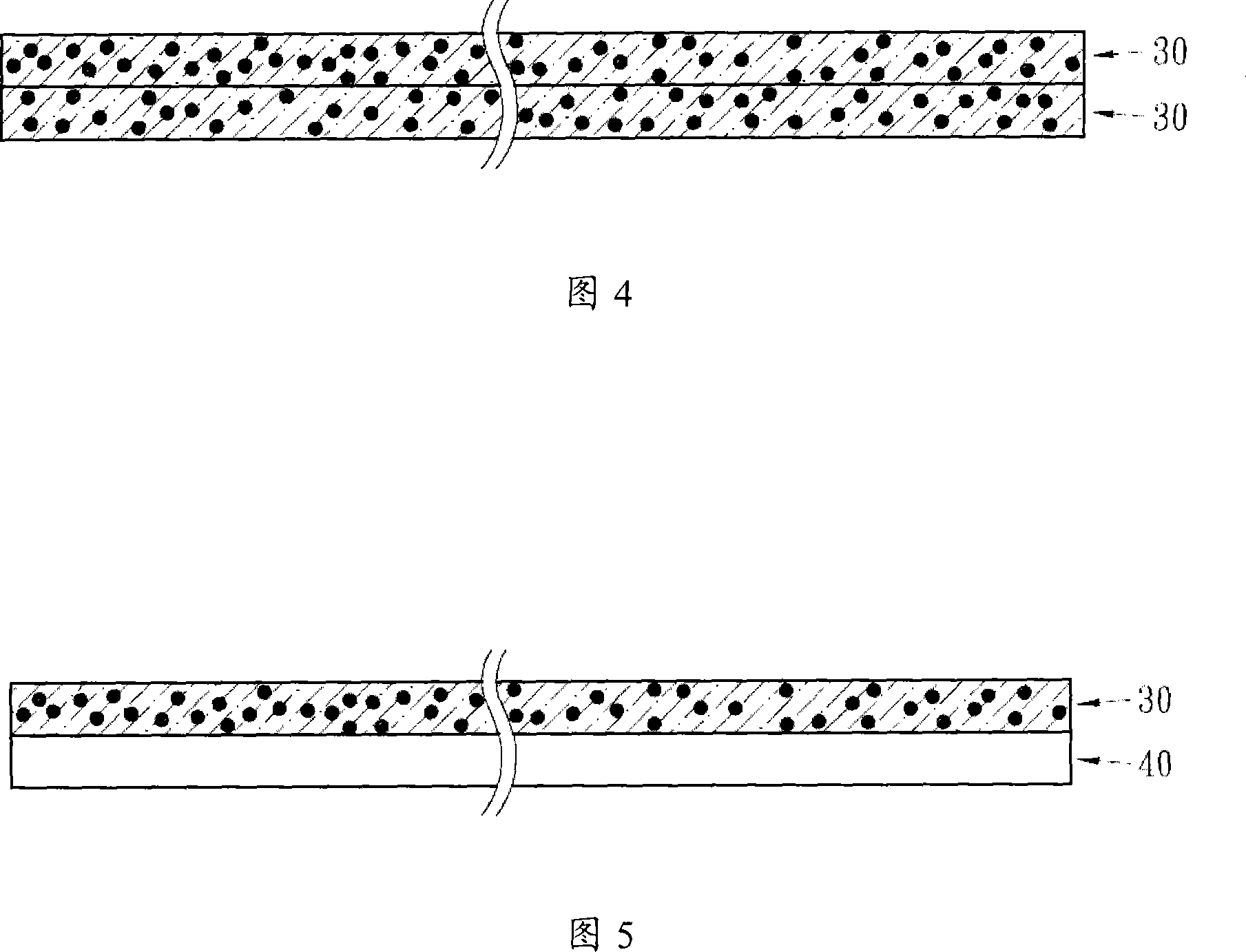

[0046] Production of heat-insulating polyvinyl chloride transparent tape 30 with a thickness of 0.2mm and a softness of 40PHR is as follows:

[0047] (1) According to the specific formula in Table 1, polyvinyl chloride resin, plasticizer, inorganic heat-insulating particles, additives (including modifiers, surfactants, dispersants and ultraviolet absorbers), stabilizers, lubricants After the raw materials are mixed evenly with a mixer, they are introduced into a 10,000-horsepower machine for even mixing;

[0048] (2) The temperature of the material is controlled at 160-180°C. After being gelled by the roller machine, the fully reacted mixture is made into a hot-melt adhesive cloth with a thickness of 0.2mm by calendering, and then introduced into water at a temperature of 20-85°C to cool and harden. ;

[0049] (3) After dewatering, the adhesive tape is introduced into the cooling wheel group to cool and set, and then coiled to obtain a heat-insulating polyvinyl chloride trans...

Embodiment 2

[0052] Except that the thickness is 0.3 mm, the raw material formula and preparation method of the heat-insulating polyvinyl chloride transparent tape 30 are the same as those in Example 1.

[0053] The test results are shown in Table 1, which shows that the heat-insulating transparent polyvinyl chloride adhesive tape 30 with a thickness of 0.3mm still has good transparency, infrared shielding rate and ultraviolet blocking rate, and there will be no precipitation of ATO during processing .

Embodiment 3

[0055] In addition to using air blowing, according to the specific formula in Table 1, use the method of Example 1 to produce a heat-insulating polyvinyl chloride transparent adhesive tape 30 with a thickness of 0.02mm and a softness of 40PHR.

[0056] The test results are shown in Table 1, which shows that the heat-insulating PVC transparent adhesive tape 30 with a thickness of 0.02mm has good transparency, infrared shielding rate and ultraviolet blocking rate, and there is no precipitation of ATO during processing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Softness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com