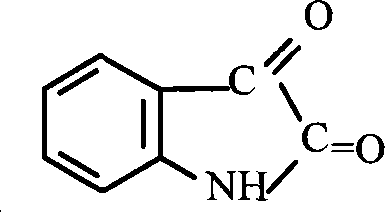

Method for preparing isatin

A technology of isatin and hydroxylamine sulfate, applied in organic chemistry and other directions, can solve the problems of low melting point, low product purity of isatin, and low product purity, and achieve the effect of improving internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

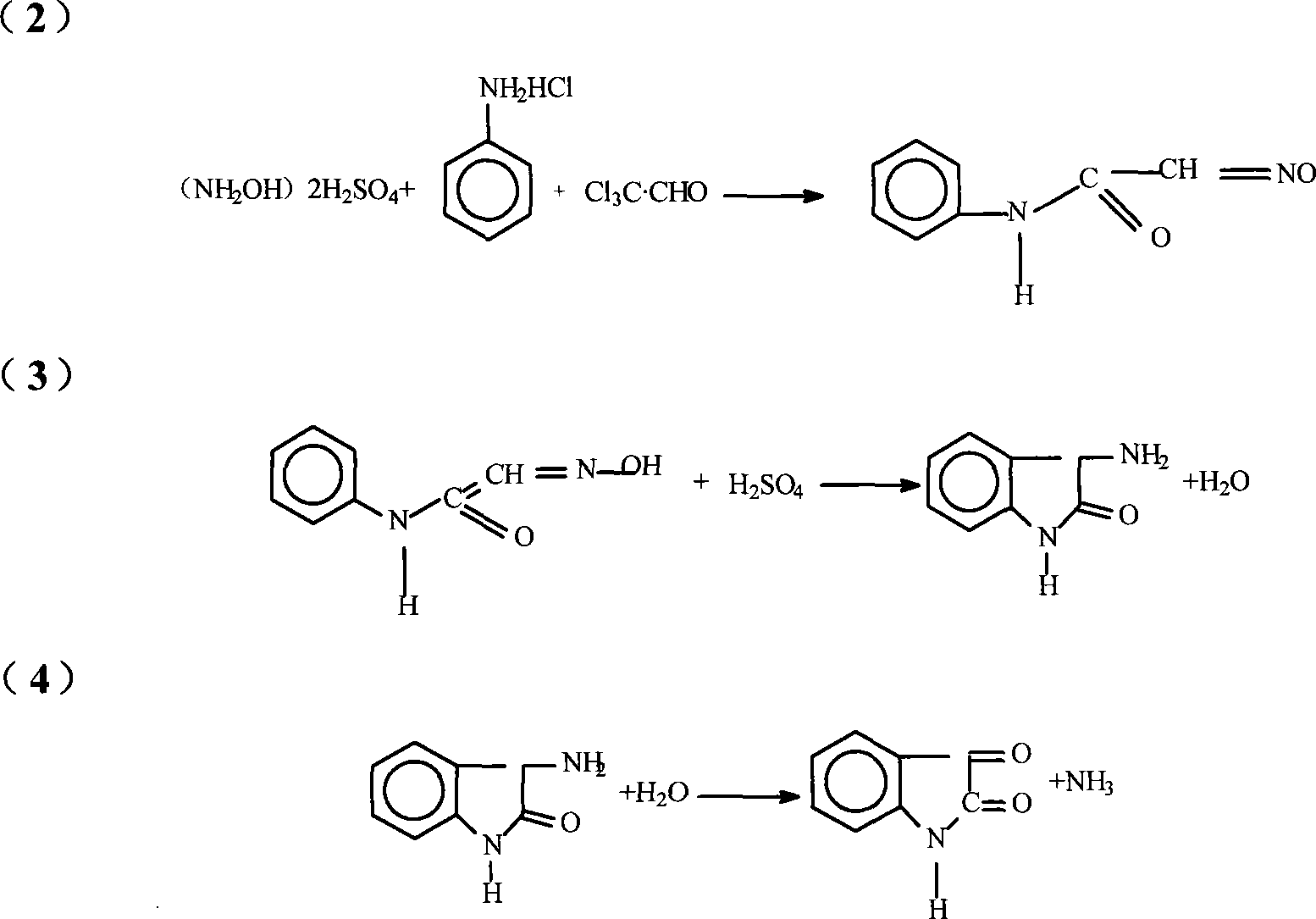

[0021] A kind of method for preparing isatin according to the present embodiment comprises following five steps:

[0022] (1) Put 100ml of water, 20g of sodium nitrite, and 15g of soda ash into a 250ml four-necked flask equipped with heating, stirring, thermometer and dropping funnel. Stir, control the temperature below 15°C, and feed in 25 grams (about 9.2 L) of sulfur dioxide for about 6 hours. After the aeration was completed, the temperature was raised to boiling for about 1 hour, and cooled to 40° C. to obtain 100 grams of hydroxylammonium sulfate.

[0023] (2) Put 100 grams of hydroxylamine sulfate into a four-necked flask, add 54.6 grams each of aniline and hydrochloric acid, heat up to 50 ° C, and after about 20 minutes, add 43.6 grams of 100% chloral, and then use 1 hour to raise the temperature Boiling (98°C), heat preservation for 5 minutes, rapid cooling to 30°C, standing for 1 hour and then filtering; washing with cooling water until neutral, drying to obtain 64....

Embodiment 2

[0029] A method for preparing isatin according to this embodiment includes five steps, the operation of the first four steps is the same as above, and in the fifth step, the filter cake obtained by the first four steps is added to ethanol, heated, and the insoluble matter Remove by filtration, collect the filtrate, wait for cooling, and the isatin product is precipitated.

[0030] It has been determined that the content of isatin is 99.6%; the initial melting point is 201°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com