Portable vehicle mounted dualpurpose wrench

A dual-purpose, hand-sleeve technology, applied in the direction of wrench, metal processing, wrench, etc., can solve the problems of high failure rate, tightening nut tightness, inability to accurately control torque, inconvenient upper and lower lines, etc., to achieve light and fast handling. Hands on and off rail lines, light weight, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

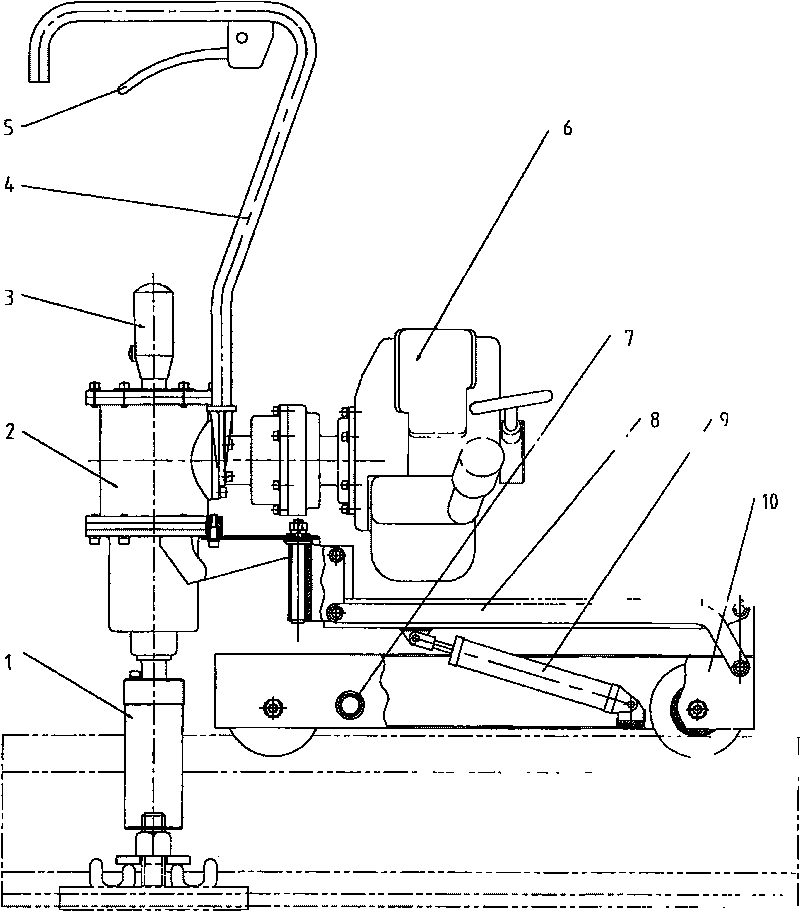

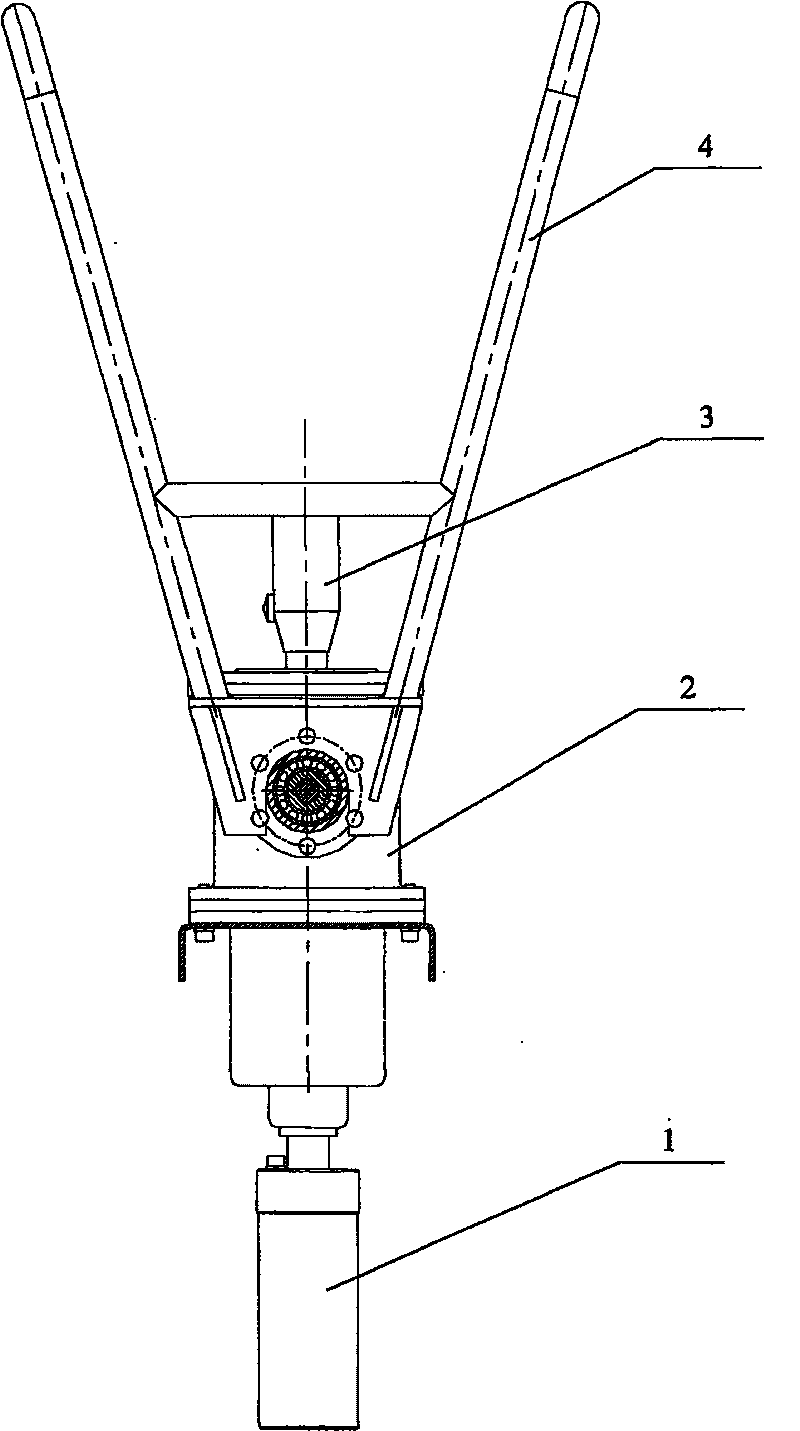

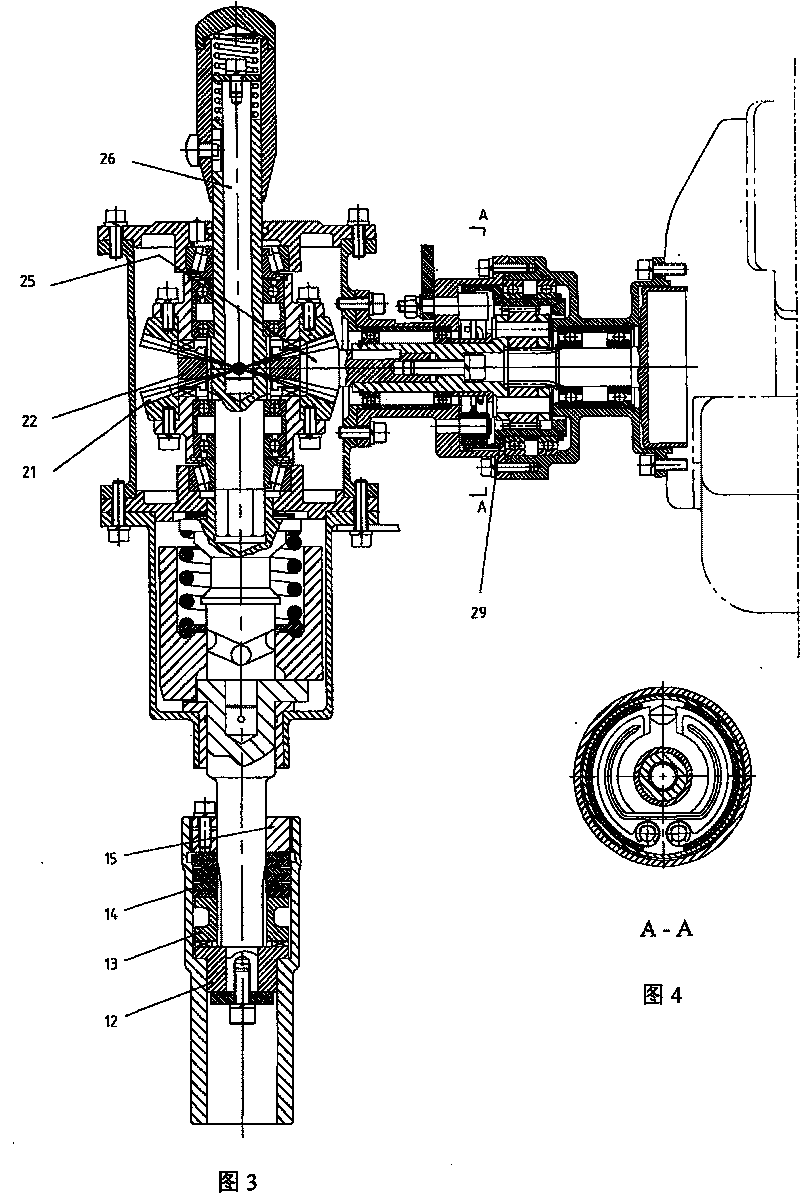

[0020] The present invention uses a gasoline engine as the power source 6, which is suitable for the maintenance of railway sleeper bolts and other occasions without power supply where it is inconvenient to use a power supply or no power supply. The system is composed of two parts, through the gripping or loosening of the clutch handle 5, the tension and floating of the ring gear 29 in the planetary gear train are controlled, thereby decelerating the gasoline engine and controlling the power output; in the wrench main body 2 In the internal bevel gear train mechanism, the two large bevel gears 21 engage with the pinion gear 25 at the same time, and rotate in opposite directions. Pull up through the reversing handle 3, drive the spline sleeve 22 to combine with the upper large bevel gear 21, and pass through The reversing handle 3 is pressed down, and the driving spline sleeve 22 is combined with the lower large bevel gear 21 to achieve the reversing purpose of forward and rever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com