Electric field ruggedization assembled method and apparatus of polyelectrolyte complexes membrane

A polyelectrolyte and assembly device technology, which is applied in the field of membrane separation and can solve the problems of poor controllability of the membrane structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

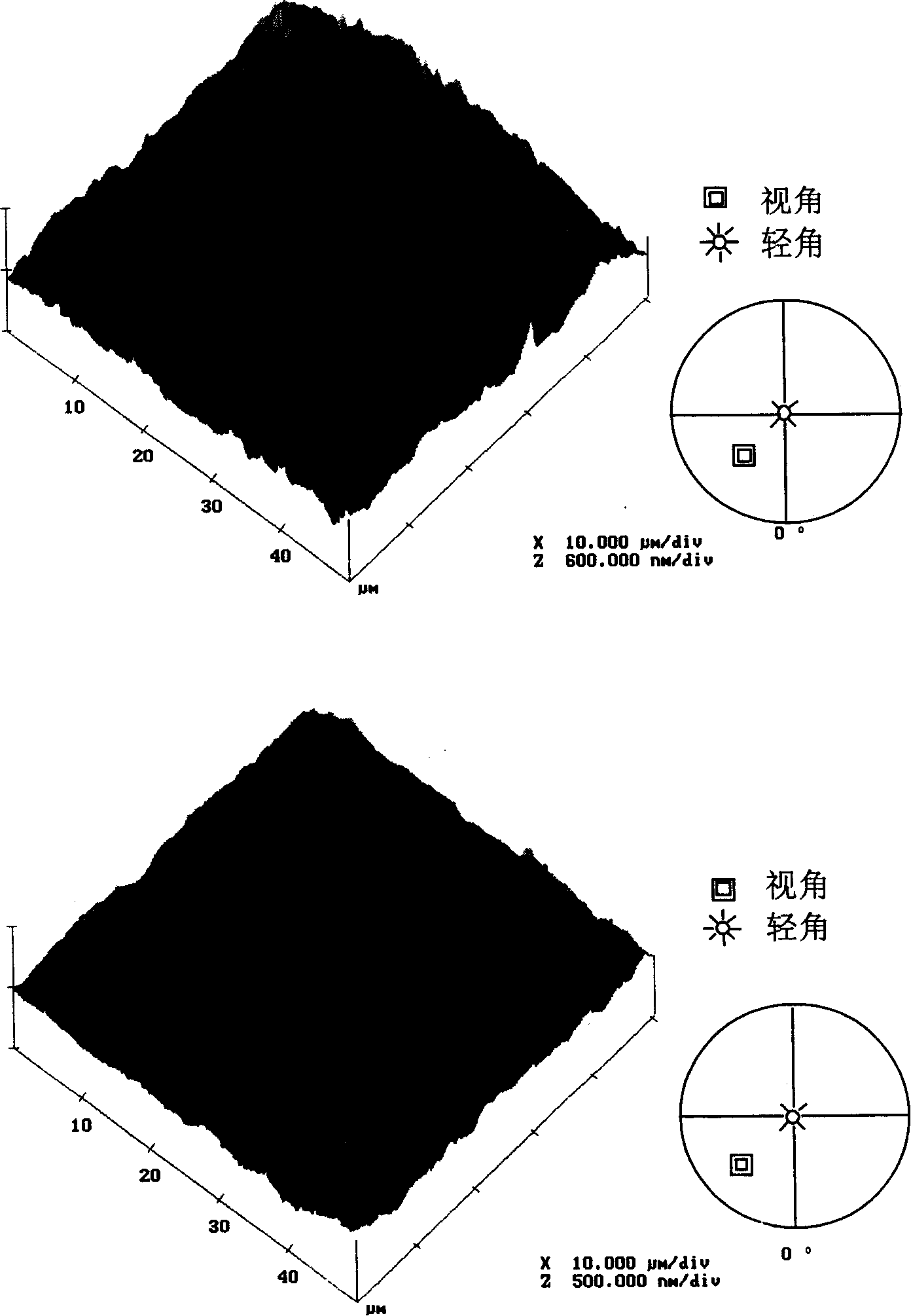

Embodiment 1

[0042] The support membrane is made of polyacrylonitrile (PAN) material, a flat ultrafiltration membrane with a molecular weight cut-off of 20,000 and a membrane area of 79cm 2 , the polycation material used is linear polyethyleneimine (PEI, molecular weight is 60,000), and the solvent of polyethyleneimine is absolute ethanol.

[0043] Assembly conditions and methods:

[0044] (1) Polyethyleneimine is made into a 0.5wt% solution with absolute ethanol, and left to defoam;

[0045] (2) In order to charge the surface of the polyacrylonitrile support membrane, conventional hydrolysis modification technology is adopted. Firstly, when the temperature is 65 ° C, the polyacrylonitrile ultrafiltration membrane is immersed in 2N NaOH solution for 30 minutes, and it is modified into Polyanion supported membrane;

[0046] (3) soak the membrane in deionized water, rinse the membrane surface and dry;

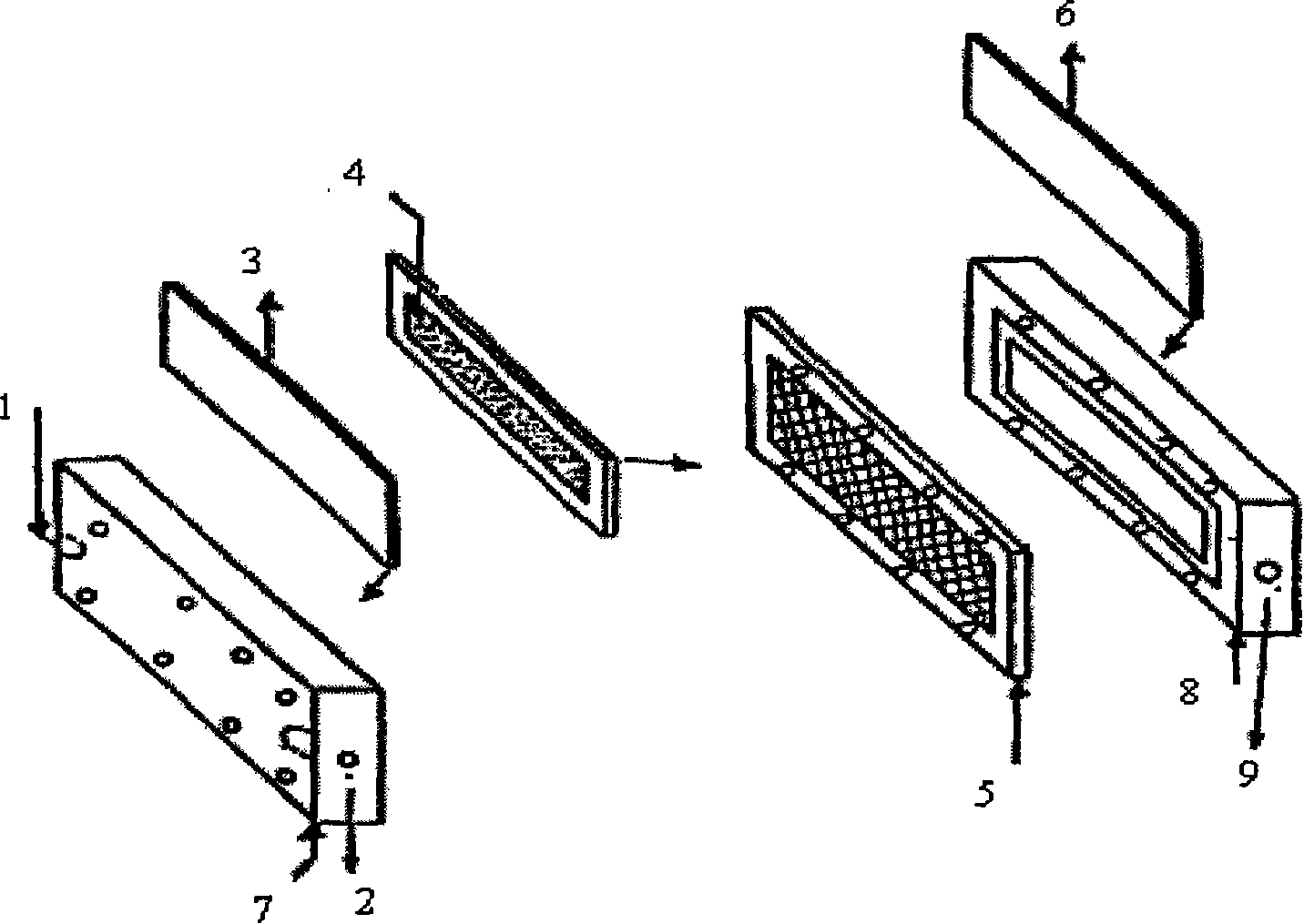

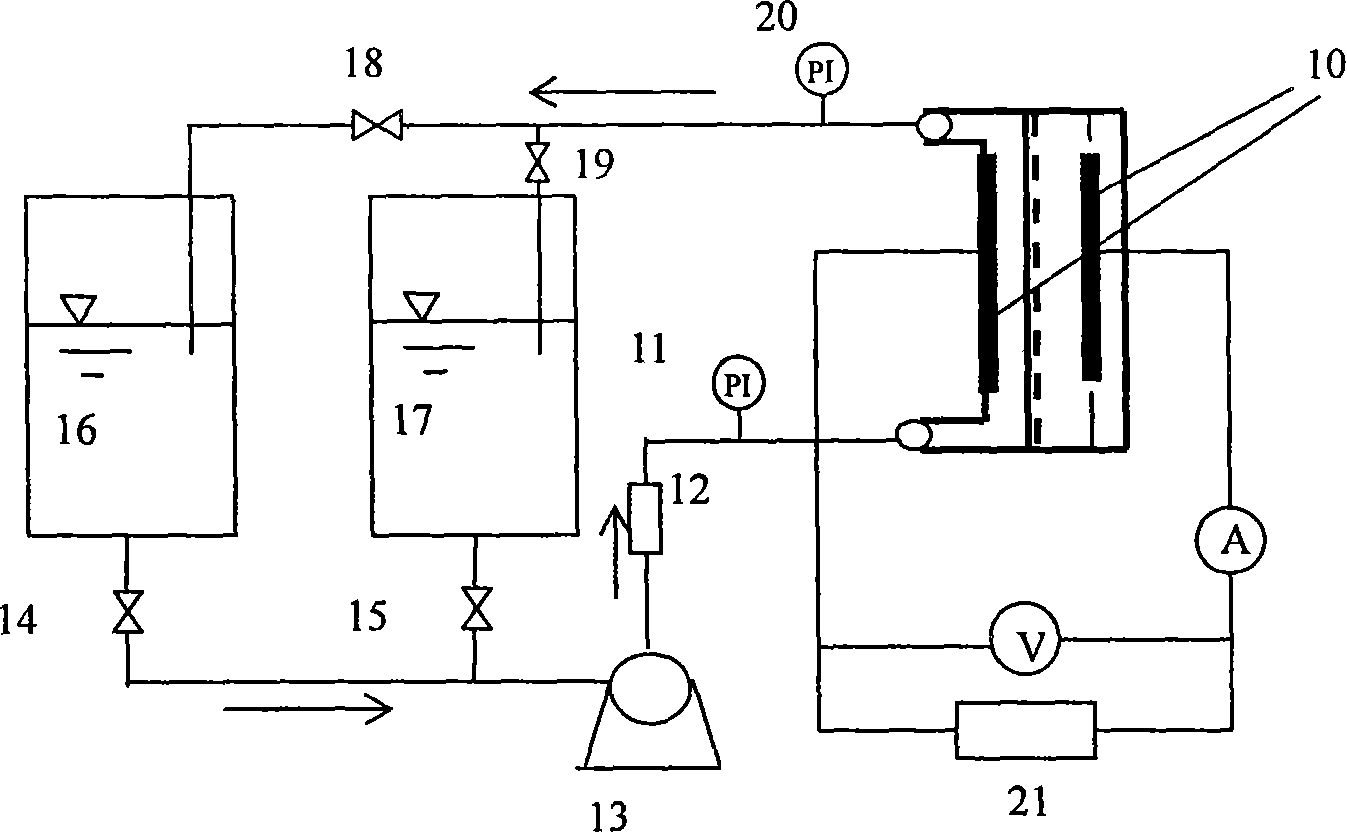

[0047] (4) Place the membrane in the membrane chamber, assemble it into an electric ...

Embodiment 2

[0053] The support membrane is made of polyacrylonitrile (PAN) material, a flat ultrafiltration membrane with a molecular weight cut-off of 20,000 and a membrane area of 79cm 2 , the polycation material used is linear polyethyleneimine (PEI, molecular weight is 60,000), polyanion is polyacrylic acid (PAA, molecular weight is 4 million), and the solvent of polyethyleneimine and polyacrylic acid is water.

[0054] Assembly conditions and methods:

[0055] (1) Polyacrylic acid is made into a 0.05wt% solution with deionized water, polyethyleneimine is made into a 0.5wt% solution with isopropanol, and left to defoam;

[0056] (2) In order to charge the surface of the polyacrylonitrile support membrane, conventional hydrolysis modification technology is adopted. Firstly, when the temperature is 65 ° C, the polyacrylonitrile ultrafiltration membrane is immersed in 2N NaOH solution for 30 minutes, and it is modified into Polyanion supported membrane;

[0057] (3) soak the membrane...

Embodiment 3

[0066] The support membrane is made of polyacrylonitrile (PAN) material, a flat ultrafiltration membrane with a molecular weight cut-off of 20,000 and a membrane area of 79cm 2 , the polycation material used is linear polyethyleneimine (PEI, molecular weight is 60,000), and the polyanion is polyacrylic acid (PAA, molecular weight is 4 million).

[0067] Assembly conditions and methods:

[0068] (1) Polyacrylic acid is made into a 0.05wt% solution with deionized water, polyethyleneimine is made into a 0.5wt% solution with isopropanol, and left to defoam

[0069] (2) In order to charge the surface of the polyacrylonitrile support membrane, conventional hydrolysis modification technology is adopted. Firstly, when the temperature is 65 ° C, the polyacrylonitrile ultrafiltration membrane is immersed in 2N NaOH solution for 30 minutes, and it is modified into Polyanion supported membrane;

[0070] (3) soak the membrane in deionized water, rinse the membrane surface and dry;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com