Gas combustion type hammering tool

A technology of driving tools and gas, which is applied in the direction of nailing tools, manufacturing tools, portable motorized devices, etc., can solve the problems of frictional impact, insufficient impact buffer, motor damage, etc., and achieve the effect of mitigating impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

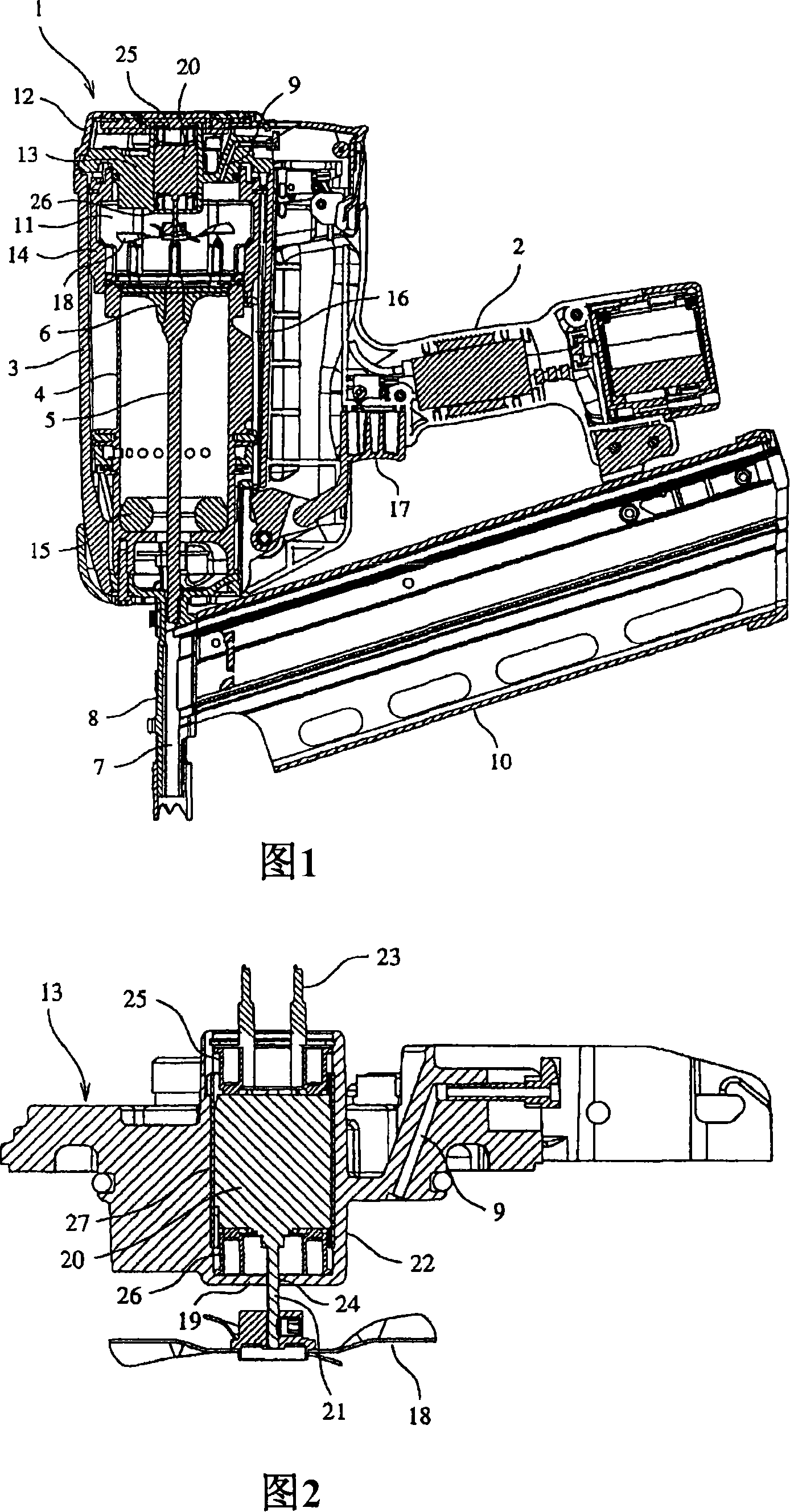

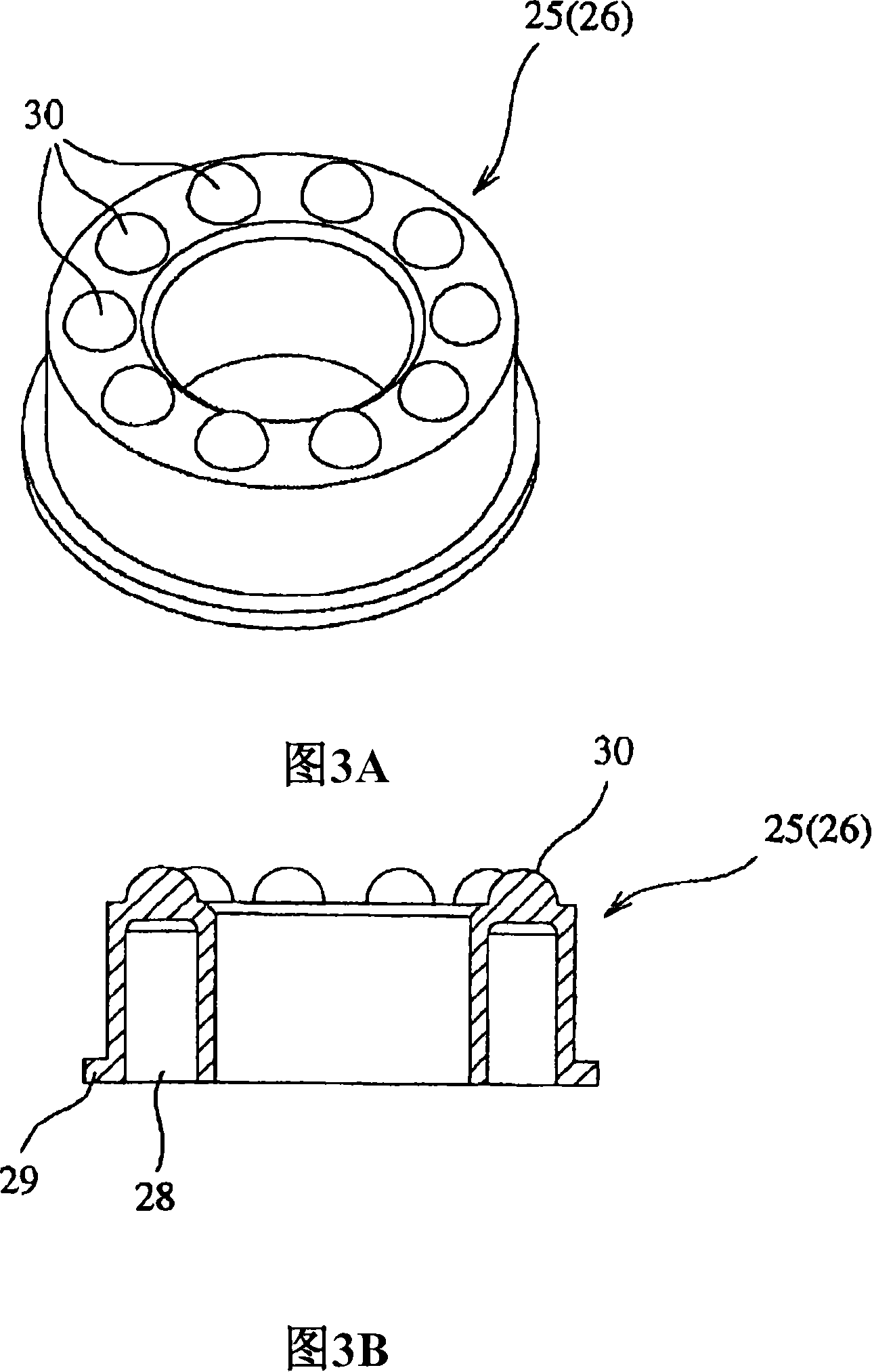

[0036] Hereinafter, typical embodiments of the present invention will be described with reference to the drawings.

[0037] In Fig. 1, reference numeral 1 is a gas combustion type nailing machine, and an impact cylinder 4 is provided in a casing 3 integrally provided with a handle 2, and an impact piston 6 is accommodated in the impact cylinder 4 so as to be slidable in an up and down direction. The impact piston 6 has a driver 5 for hammering nails. The bottom of above-mentioned casing 3 is formed with the nozzle part 8 that has ejection port 7, and the rear side of nozzle part 8 is connected with the nail case 10 that loads and connects nail 9, and the nail in the nail case 10 is supplied to ejection port successively, and by The above-mentioned nailer 5 strikes and nails into the material to be driven from the injection port 7 .

[0038] A combustion chamber 11 for generating a mixed gas of combustible gas and air and burning the mixed gas is formed above the impingement c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com