Gear drive motor

A technology of gear transmission and motor, which is applied in the direction of electric components, magnetic circuit rotating parts, and control of mechanical energy. It can solve the problems of discrete positions, difficult design of gear trains, and limited range, and achieve the effect of improving the degree of freedom of configuration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

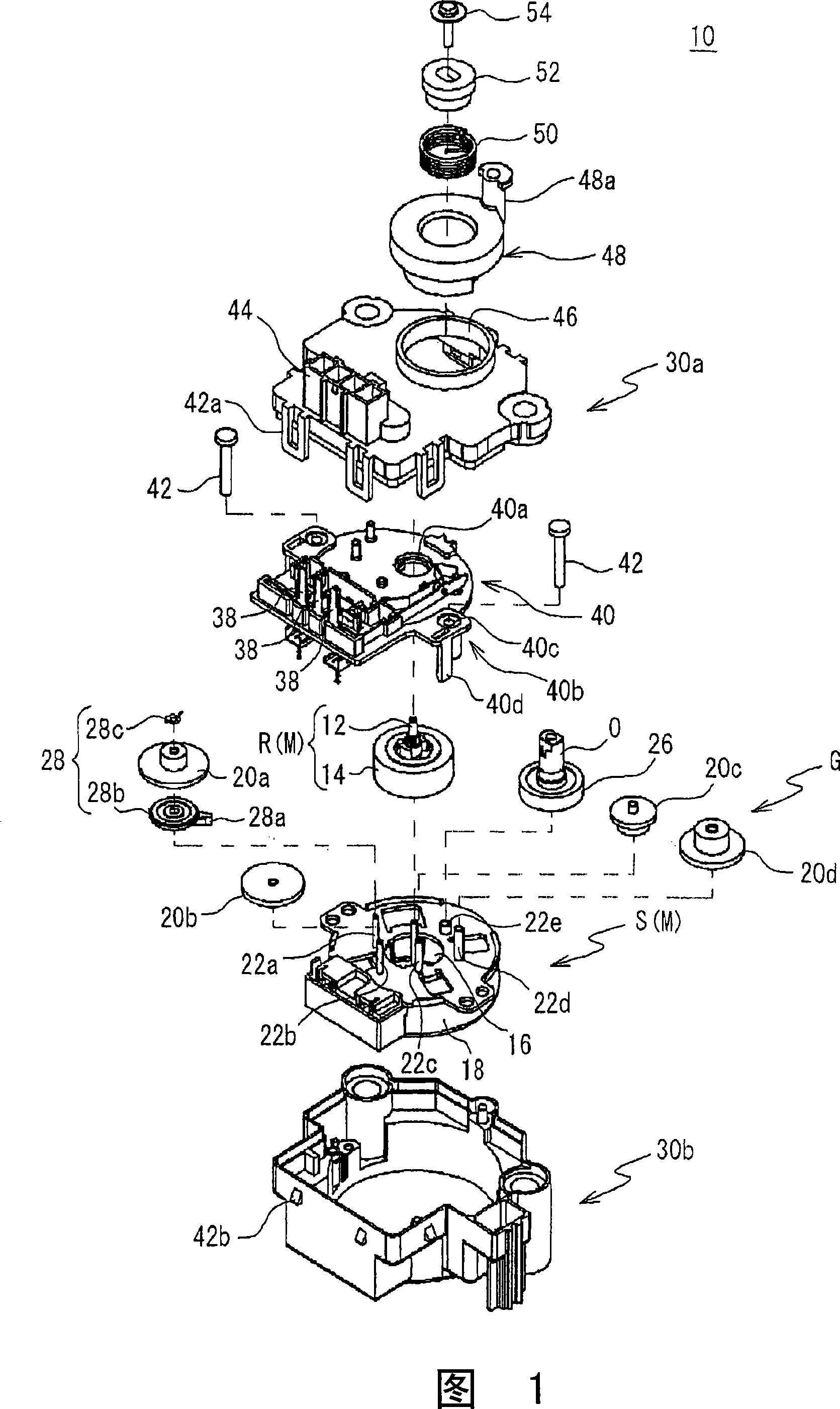

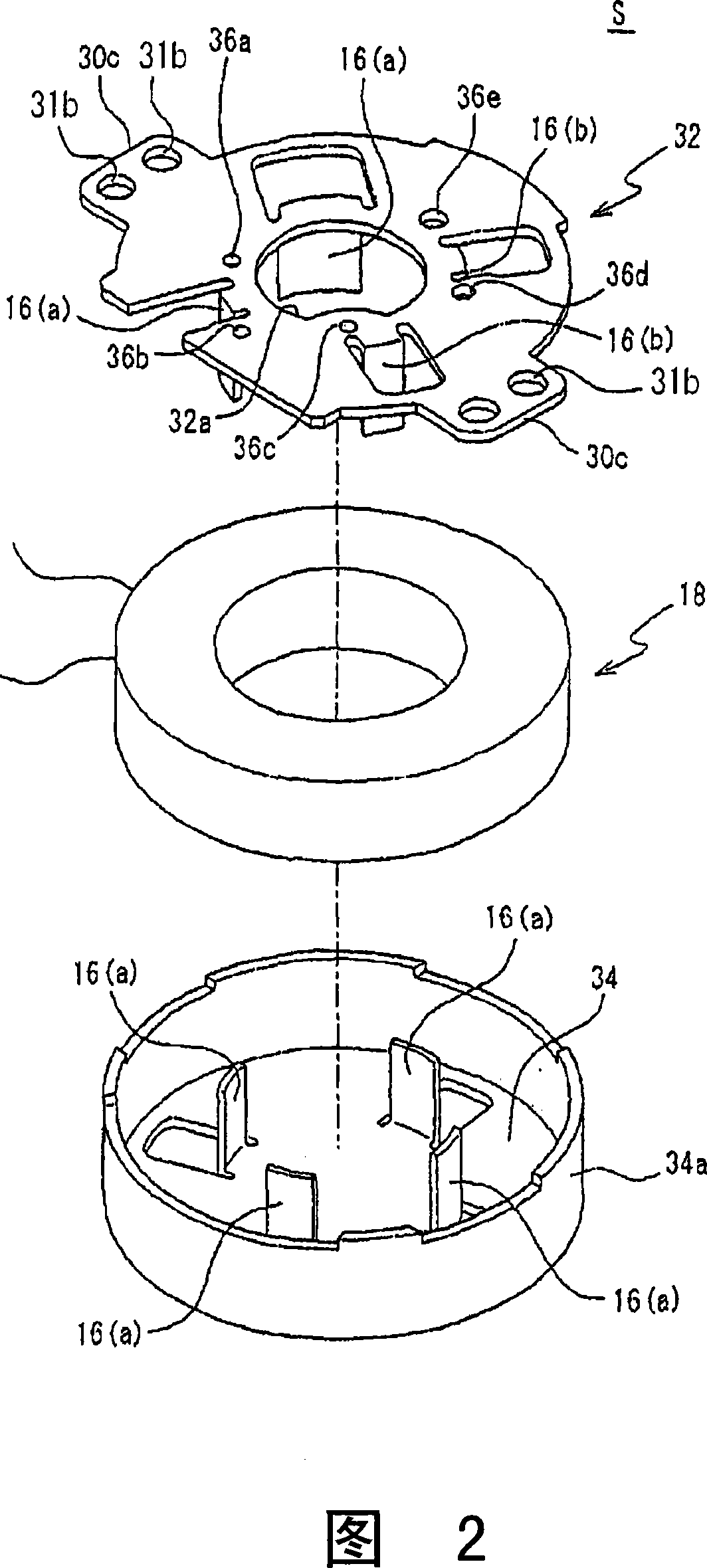

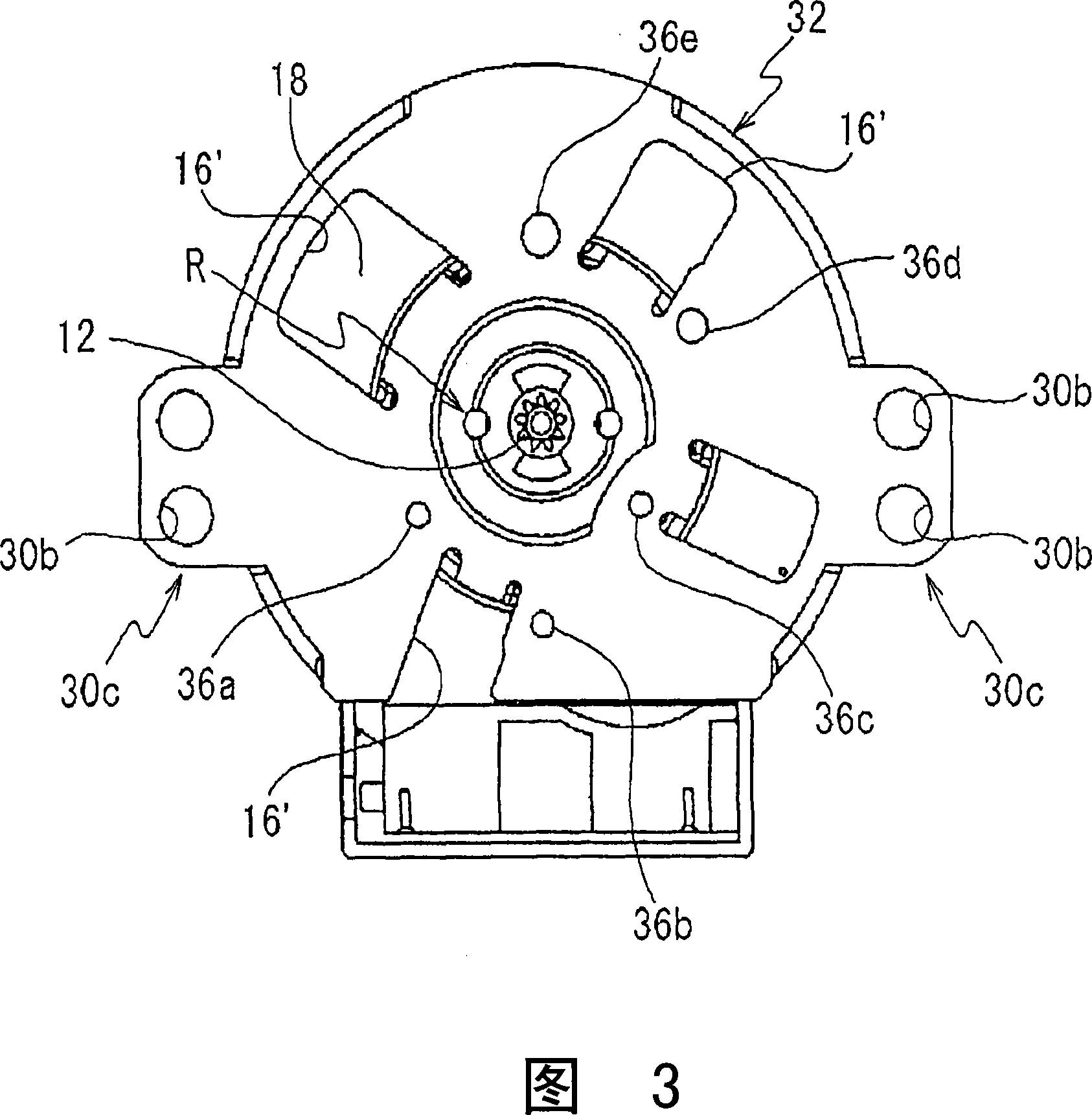

[0034] Hereinafter, a geared motor according to an embodiment of the present invention will be described in detail with reference to the accompanying drawings. FIG. 1 is an exploded perspective view showing a schematic configuration of a geared motor 10 according to an embodiment of the present invention.

[0035] As shown in FIG. 1 , a geared motor 10 according to an embodiment of the present invention is formed by accommodating a salient-pole motor M and a reduction mechanism in body casings 30 a and 30 b. The salient-pole motor M includes: around the rotating shaft 12 A rotor R formed by providing magnets; and a stator S formed by arranging a plurality of pole teeth 16, 16 . The speed reduction mechanism has a plurality of compound gears 20 a , 20 b , 20 c , and 20 d to reduce the rotation of the rotor shaft 12 of the motor M and transmit it to the output shaft 0 . The geared motor 10 decelerates the rotation supplied by the motor M to increase the rotational force, and ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com