Differential capacitance type sensor detection circuit

A technology of differential capacitance and detection circuit, which is applied in the direction of electronic circuit testing, circuit, and transmission of sensing components by electric/magnetic devices, etc., can solve the problem of low detection accuracy and achieve high detection accuracy, high reliability, and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

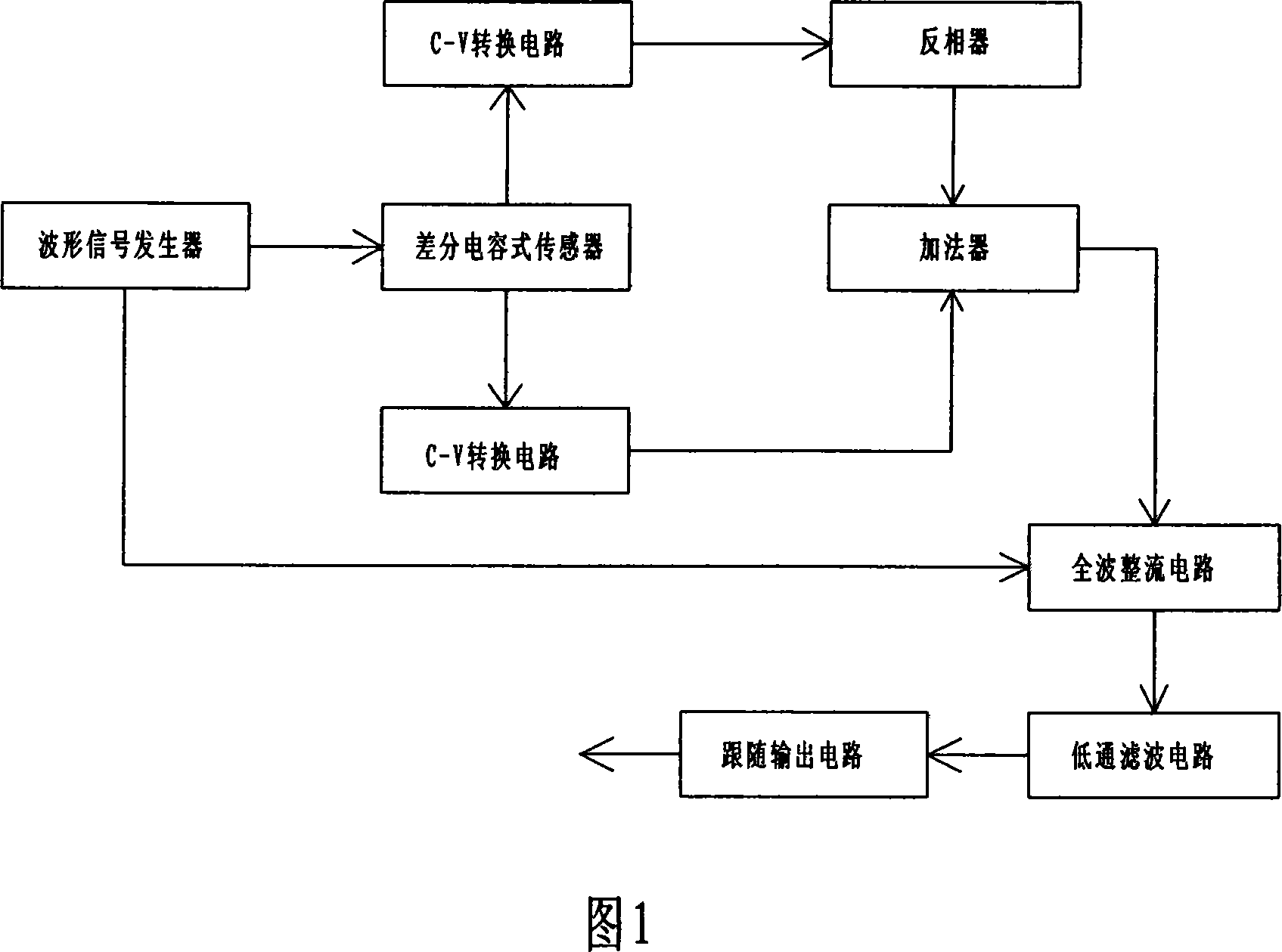

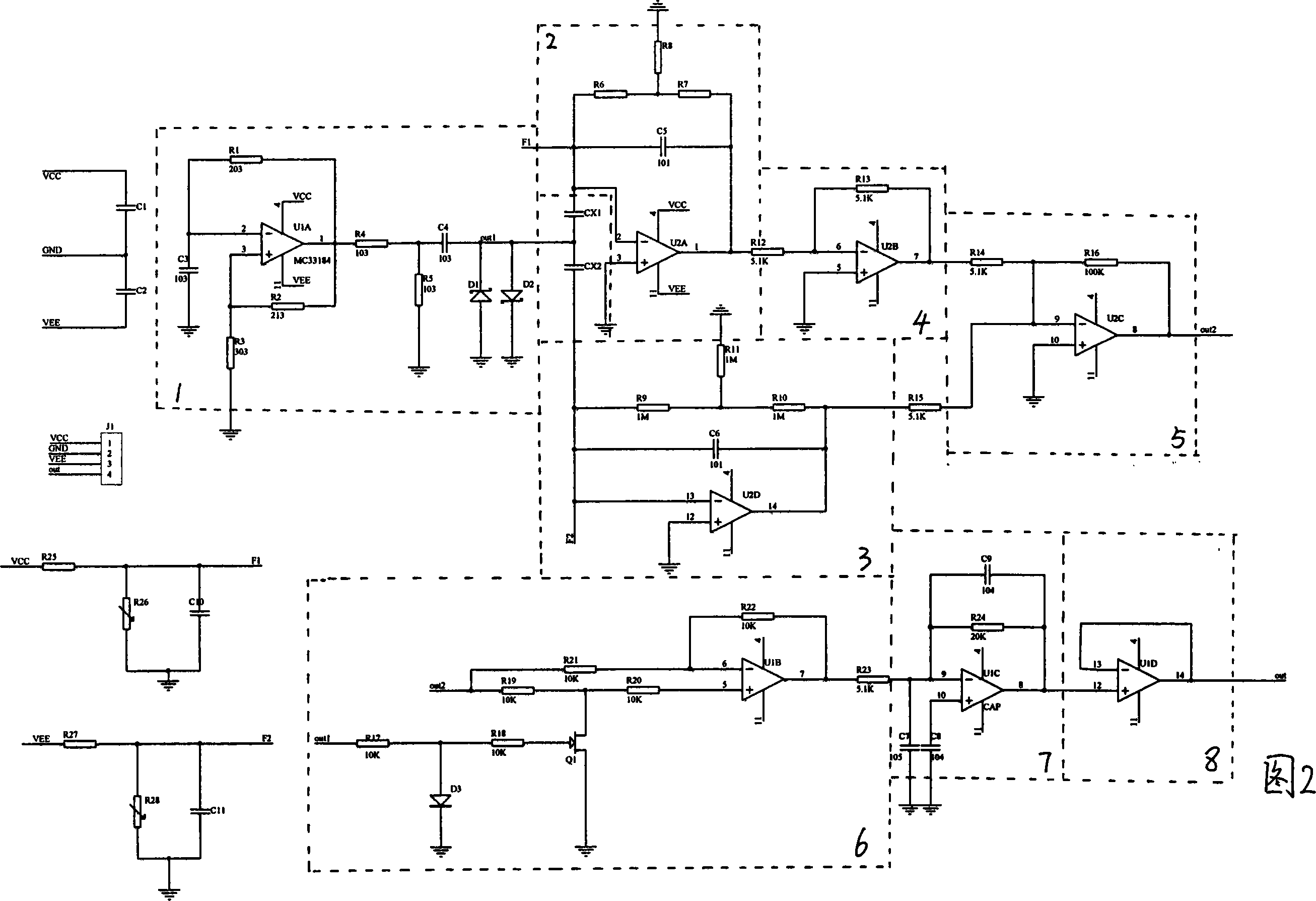

[0019] The differential capacitive sensor detection circuit includes a waveform signal generator 1, C-V conversion circuits 2 and 3, an inverter 4, an adder 5, a full-wave rectification circuit 6, a low-pass filter circuit 7, and a follower output circuit 8. The wave rectification circuit includes an integrated operational amplifier U1B and a transistor Q1. The inverting terminal of the integrated operational amplifier U1B is connected to the output terminal out2 of the adder through a resistor R21, and the non-inverting terminal is connected to the output terminal out2 of the adder through resistors R19 and R20. Resistor R22 is connected between the terminal and its output terminal, the connection node of resistors R19 and R20 is connected to the collector of transistor Q1, the base of transistor Q1 is connected to the output terminal out1 of the waveform signal generator through resistors R17 and R18, resistors R17, The connection node of R18 is grounded via diode D3. The C-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com