Light opening wedge fast flashboard machine for treating yard sludge

A technology for sludge treatment and inserting machine, which is applied in the fields of civil engineering, environmental engineering, marine engineering, and hydraulic engineering. Efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

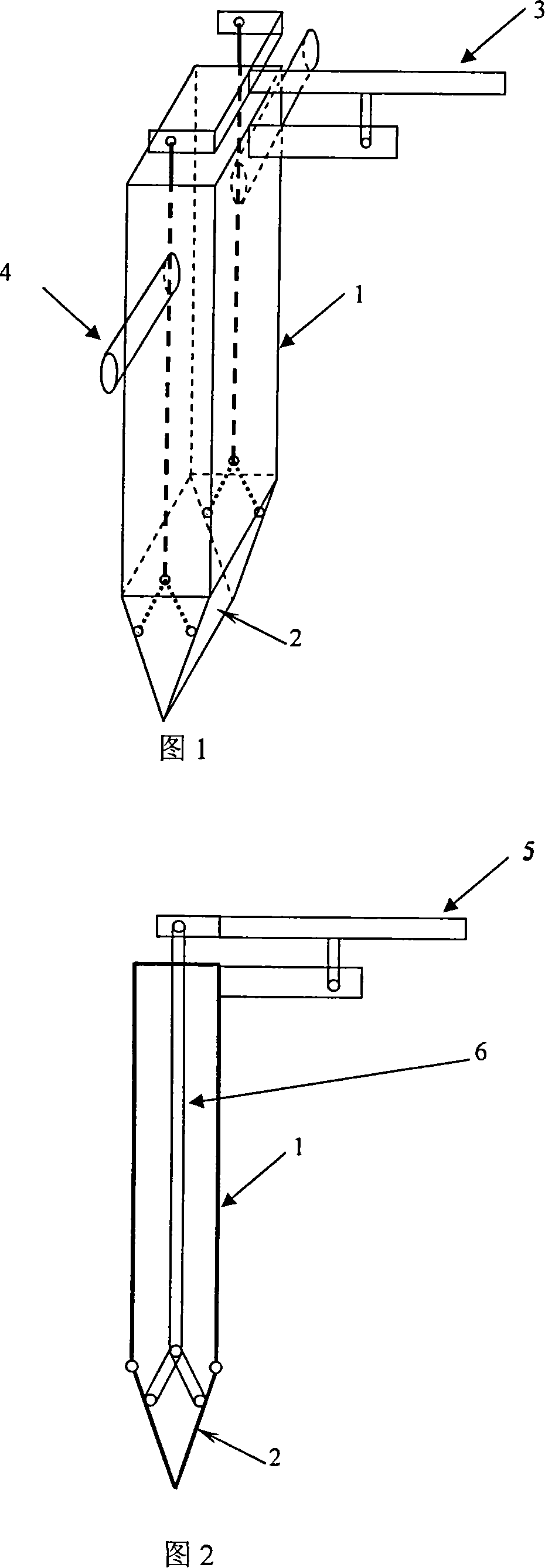

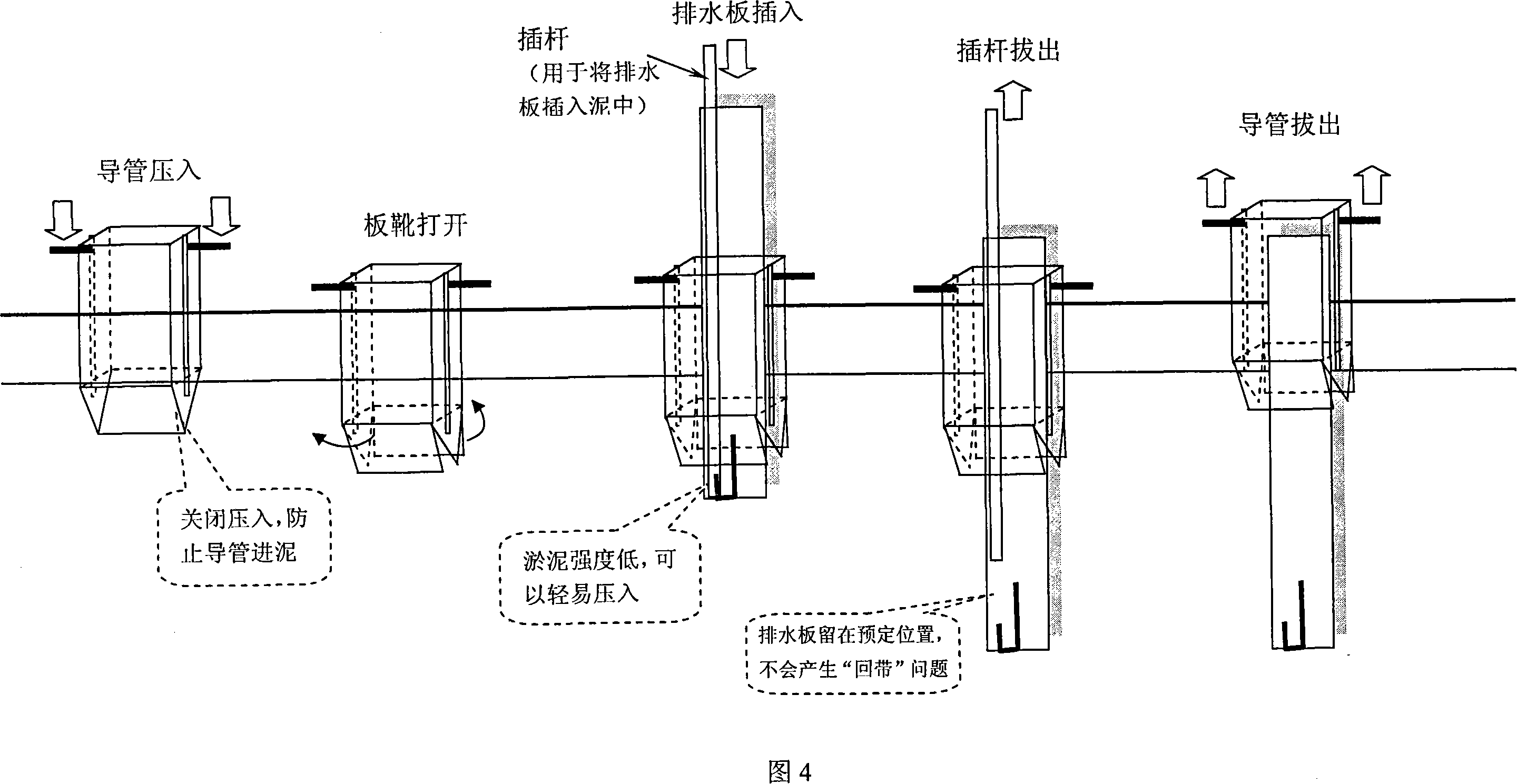

[0015] With reference to accompanying drawings 1 and 2, its structure is to comprise clutch, conduit 1, and force application lever 4, and wherein clutch is formed by the connection of clutch lever 5 and steel bar 6, and the mutually hinged steel bar 6 is hinged on clutch lever 5 and conduit On the plate shoe 2 in 1, the force applying rod 4 is welded on both sides of the upper end of the outer wall of the conduit 1.

[0016] The section of the catheter 1 is rectangular or diamond-shaped.

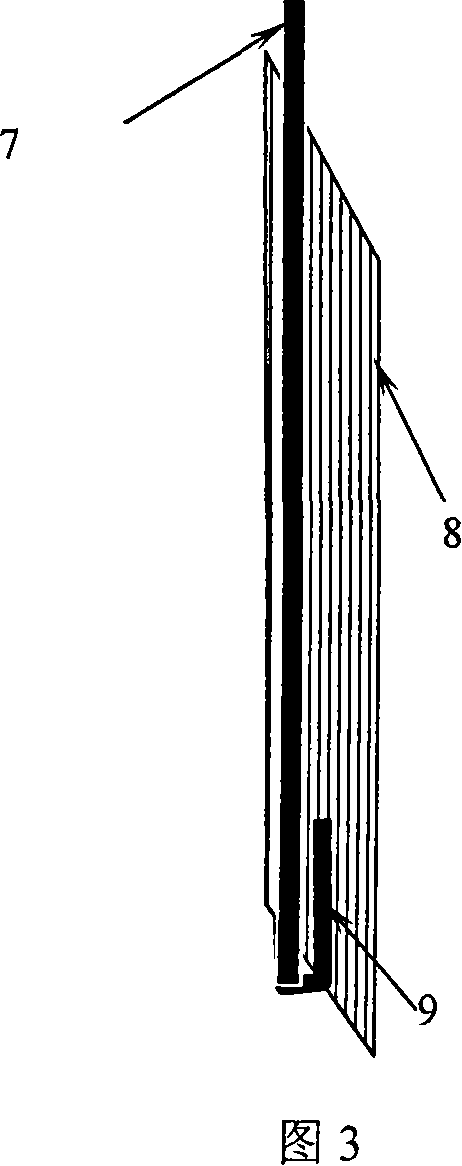

[0017] The cross-section of the inserting rod 6 is a circular, flat rectangular or elliptical metal rod or pipe, and the lower end of the inserting rod 7 has a gap, which can be easily inserted into the fastening iron hook 9 fixed on the drainage board 8 .

[0018] The board boot 2 is in the form of 2 petals or 4 petals.

[0019] One end of drain board 8 is nailed with fixing iron hook.

[0020] The clutch is hinged by three steel rods or steel rods, its upper part is hinged on the clutch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com