Vacuum preloading shallow layer solidification method based on new dredger-filled ultra-soft soil foundation

A solidification method and ultra-soft soil technology, which is applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of large impact, difficulty in guaranteeing project cost and construction period, etc., so as to reduce losses, improve soil strength, increase The effect of the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

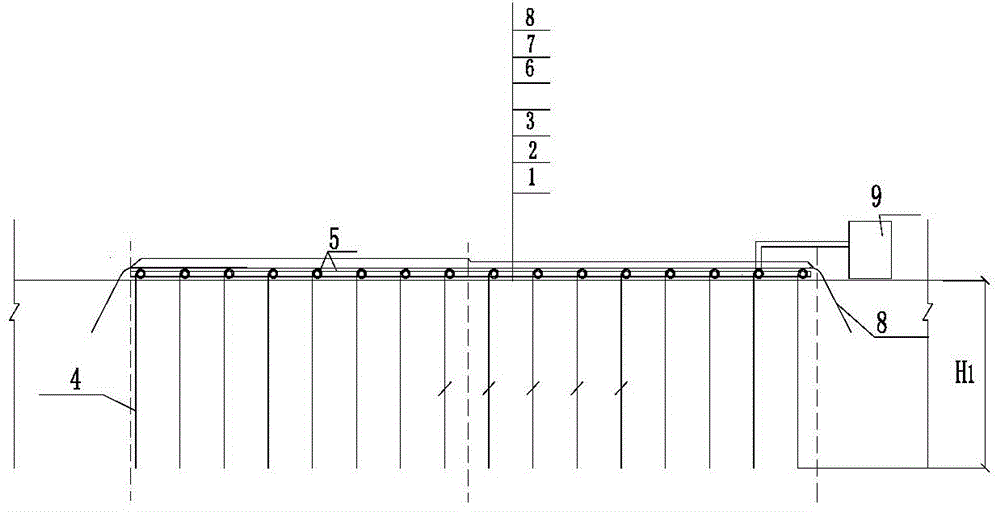

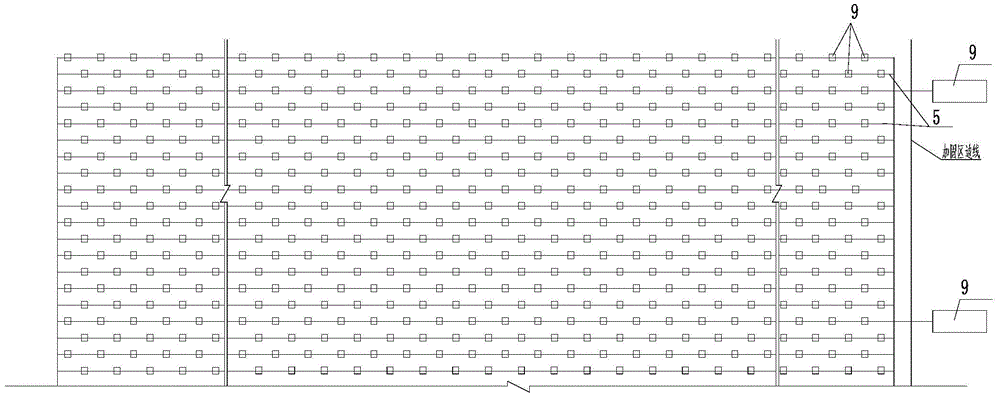

[0043] see Figure 1 to Figure 4 , a vacuum preloading shallow layer curing device based on new blow-filled ultra-soft soil foundation, the shallow layer curing device mainly includes the first layer of woven cloth layer 1 laid on the upper surface of the new blow-filled ultra-soft soil foundation; on the woven cloth layer The second layer of bramble layer 2 laid on the surface, the third layer of non-woven fabric layer 3 laid on the upper surface of the bramble;

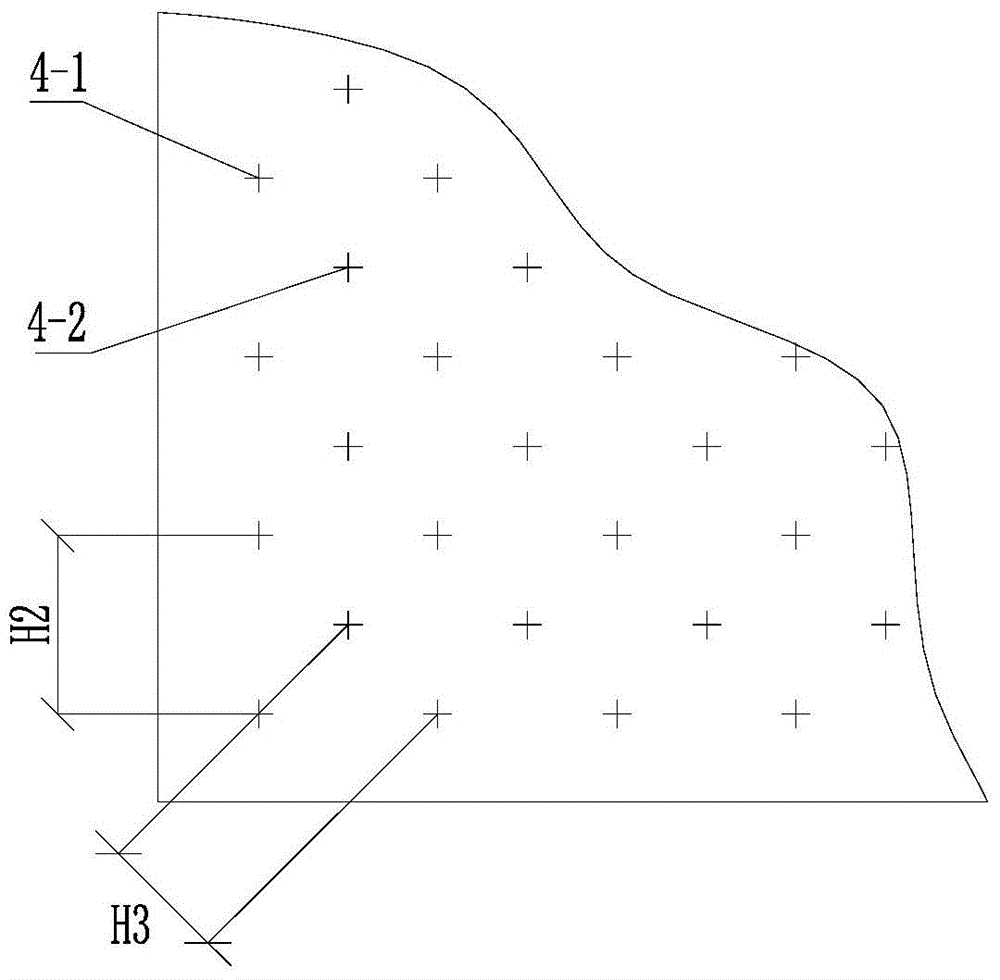

[0044]On the basis of laying the three-layer structure on the above-mentioned new dredging-filled ultra-soft soil foundation, an array of drainage boards 4 is provided along the vertical direction on the new dredged-filled super-soft soil foundation, and the depth H1 of the drainag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com