Mechanical interlocking transmission device of double power supply automatic switching switch

A technology for automatic switching of switches and transmission devices, which is applied to the power devices, electric switches, circuits and other directions inside the switch, can solve the problems of breakage of the circuit breaker handle, poor operation reliability, stuck and other problems, and achieves a small rotation angle of the motor and labor-saving operation. Also, the effect of fast switching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Through the applicant's description of the embodiments, it will be more helpful to understand the present invention, and make the advantages and effects of the present invention clearer. However, the embodiment does not constitute a limitation to the solution of the present invention. Any slight change in form or equivalent substitution or literal modification based on the concept of the present invention should be considered as belonging to the scope of the technical solution disclosed in the present invention. .

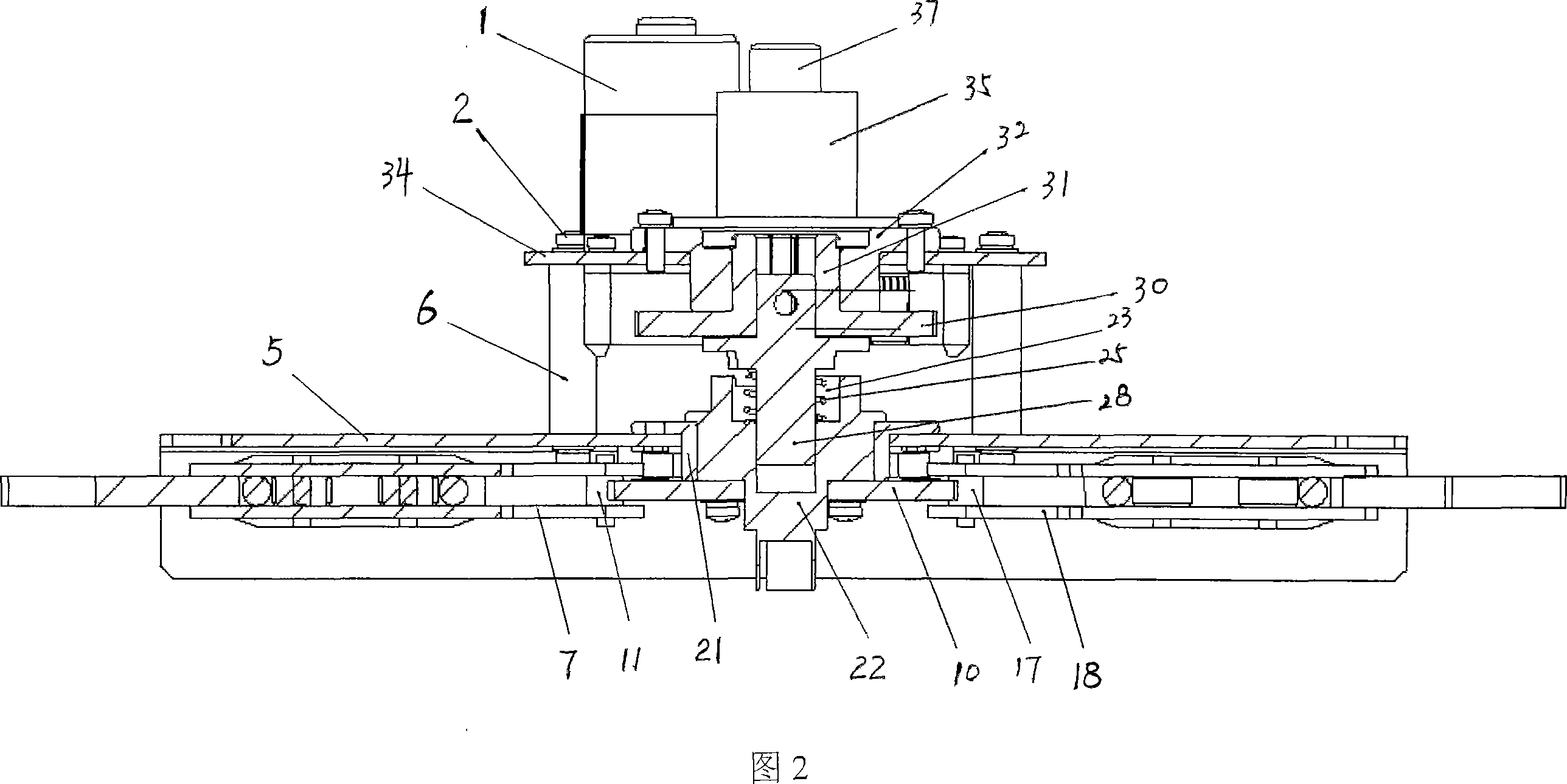

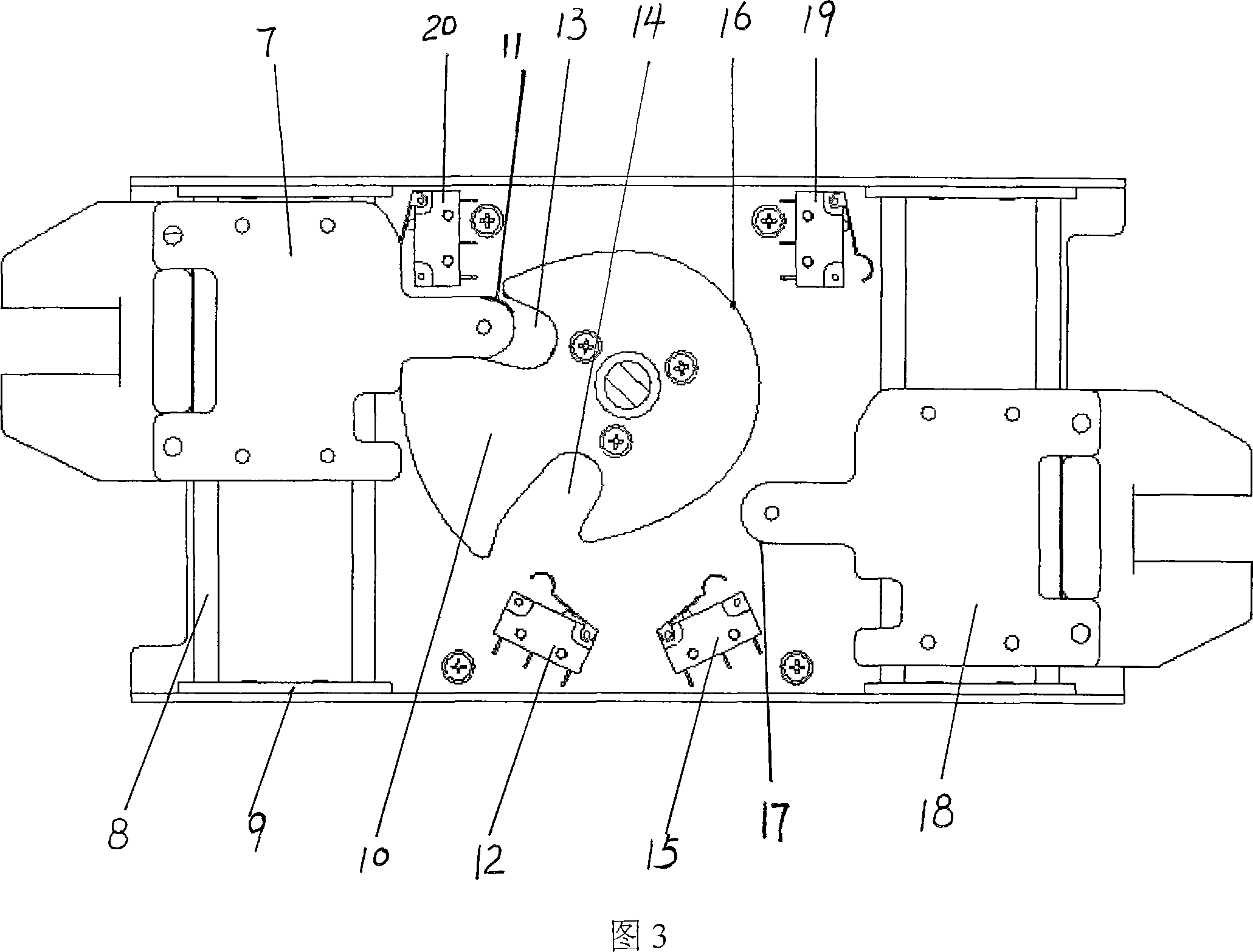

[0024] Referring to Fig. 1 and Fig. 2, the mechanical interlock transmission device of the present invention comprises an upper fixed plate 34, a motor 1, a reduction mechanism 4, a lower fixed plate 5, a transmission main shaft 22, a pair of first and second slide blocks 7, 18 and Four first, second, third, fourth microswitches 12, 15, 19, 20 and cam turntable 10, solenoid valve 35, bull gear 30, bull gear shaft 31, intermediate shaft 28. The motor 1 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com