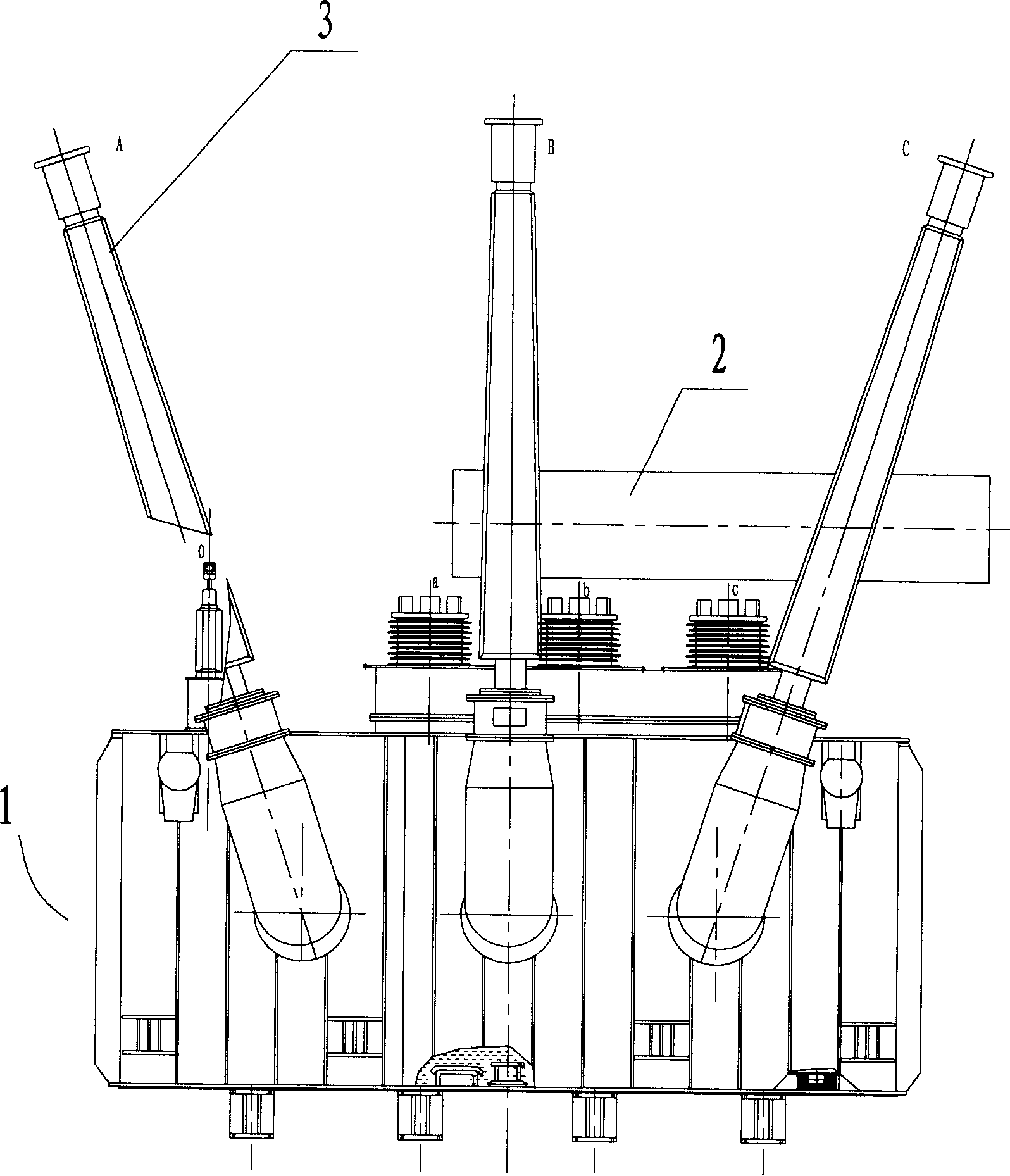

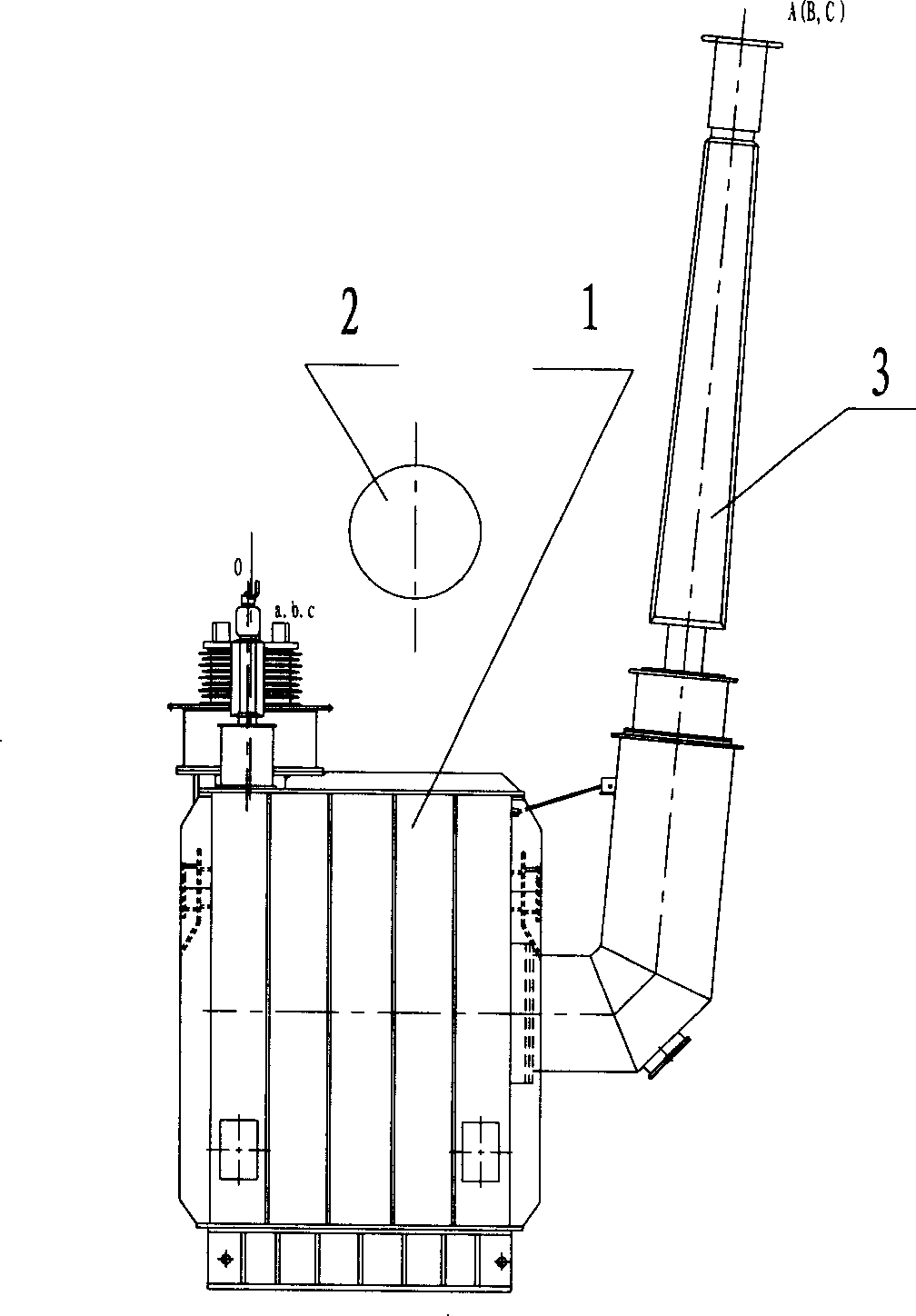

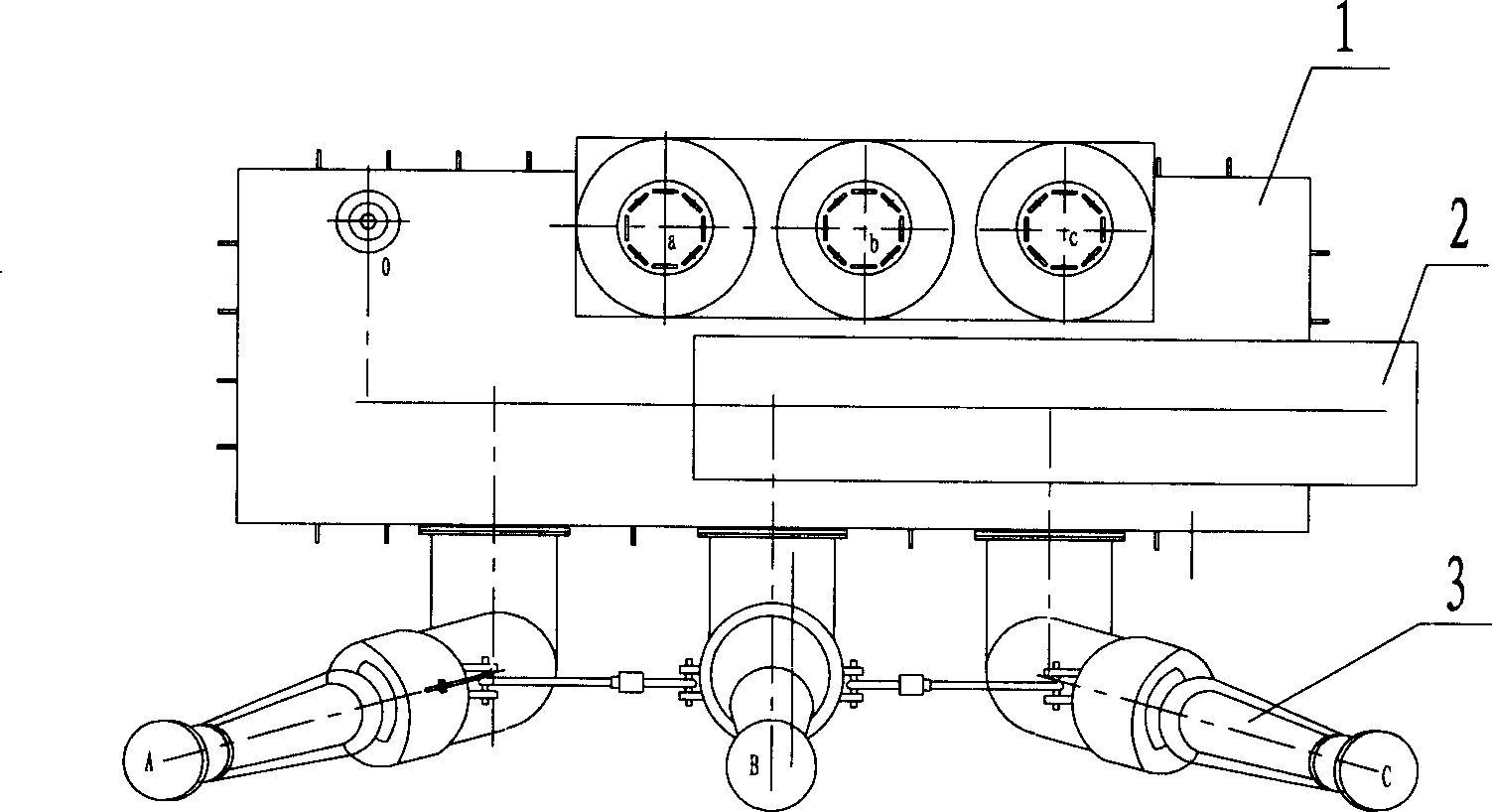

Generator transformer

A new type of generator and transformer technology, which is applied in the field of transformer manufacturing, can solve the problems of affecting the safe operation and service life of the transformer, the overall structure of the transformer is huge, and the shielding structure is complex, etc., to achieve a compact overall structure layout, reduce overheating phenomenon, and simple structural layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]As shown in Figures 4 to 12, an insulating cardboard 10 is provided between the upper and lower clamps 5, 6 of the transformer core 4 and the contact surface of the iron core 4, so that the upper and lower clamps 5, 6 of the iron core 4 are completely insulated, and the upper and lower clamps are fully insulated. The clips 5, 6 are connected to the iron core 4 through the ground wire, so that the upper and lower clips 5, 6 are grounded separately. The bolts at the joints of the upper beam 7, foot 9, side beam 8 of the upper and lower clamps 5, 6 and the limb plates 12, 13 of the upper and lower clamps are fully insulated with insulating sleeves 15 and insulating pads 16, and the two ends of the straps are fully insulated. It is fully insulated from the upper and lower clamps 5, 6, and then connected with a grounding wire to make the upper and lower clamps 5, 6 grounded separately. In this way, it is easy to find out if there is multi-point grounding of the iron core in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com