Ice maker

A technology of ice machine and ice blade, which is applied in ice making, ice making, lighting and heating equipment, etc. It can solve the problems of inability to produce fine ice chips, affect the effect of ice scraping, and the effect of ice scraping is not good, and reach the size of ice flakes Uniformity, good ice breaking effect, and the effect of improving ice scraping ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The ice maker of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

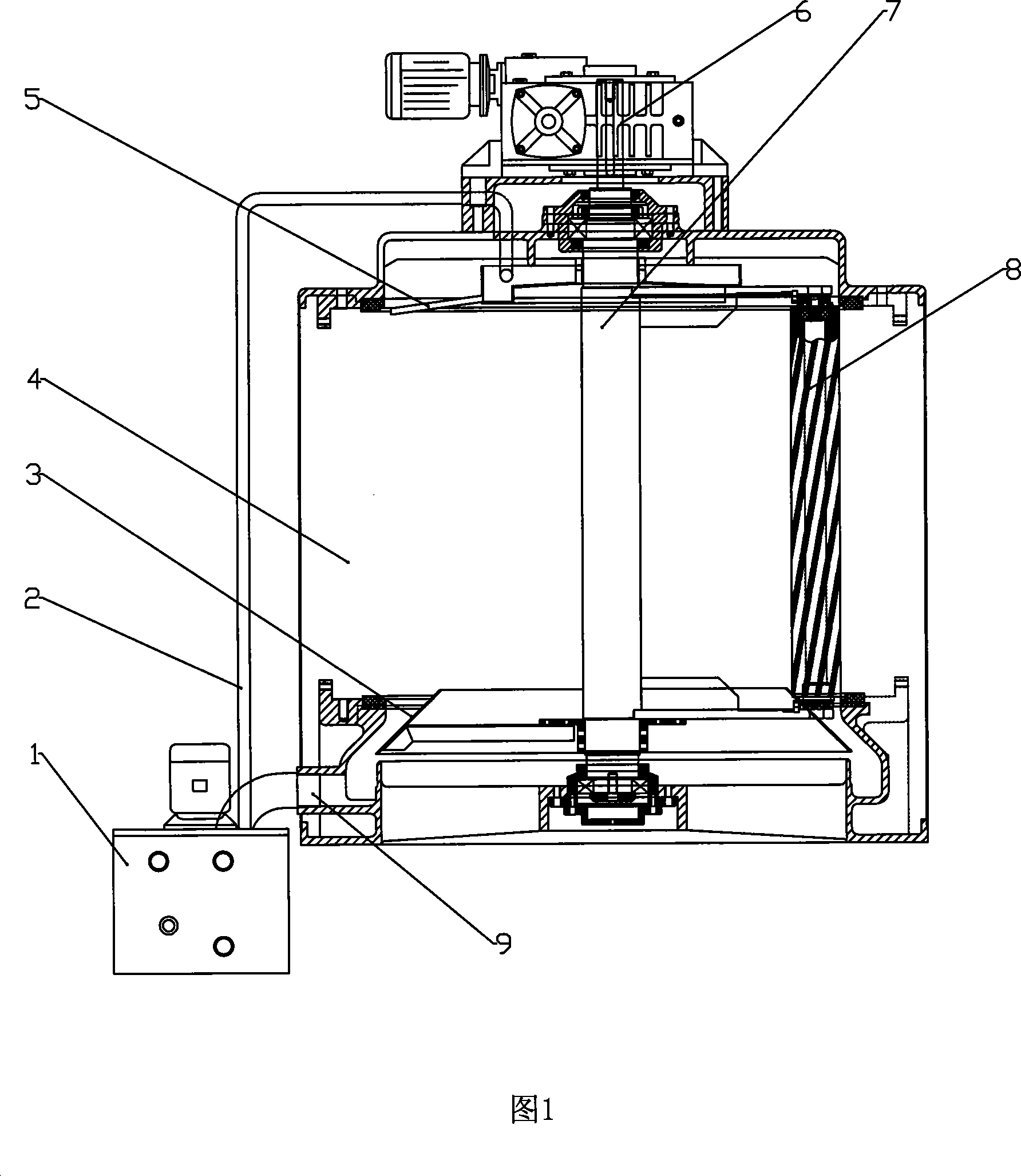

[0039] As shown in Figure 1, the ice machine includes a water tank 1, a water pump, and a water supply pipe 2 installed on the water outlet of the water pump, a water receiving tray 3, a cylindrical refrigeration evaporator 4, a water diffuser 5, a reducer 6, a main shaft 7, a water receiving Disk 8.

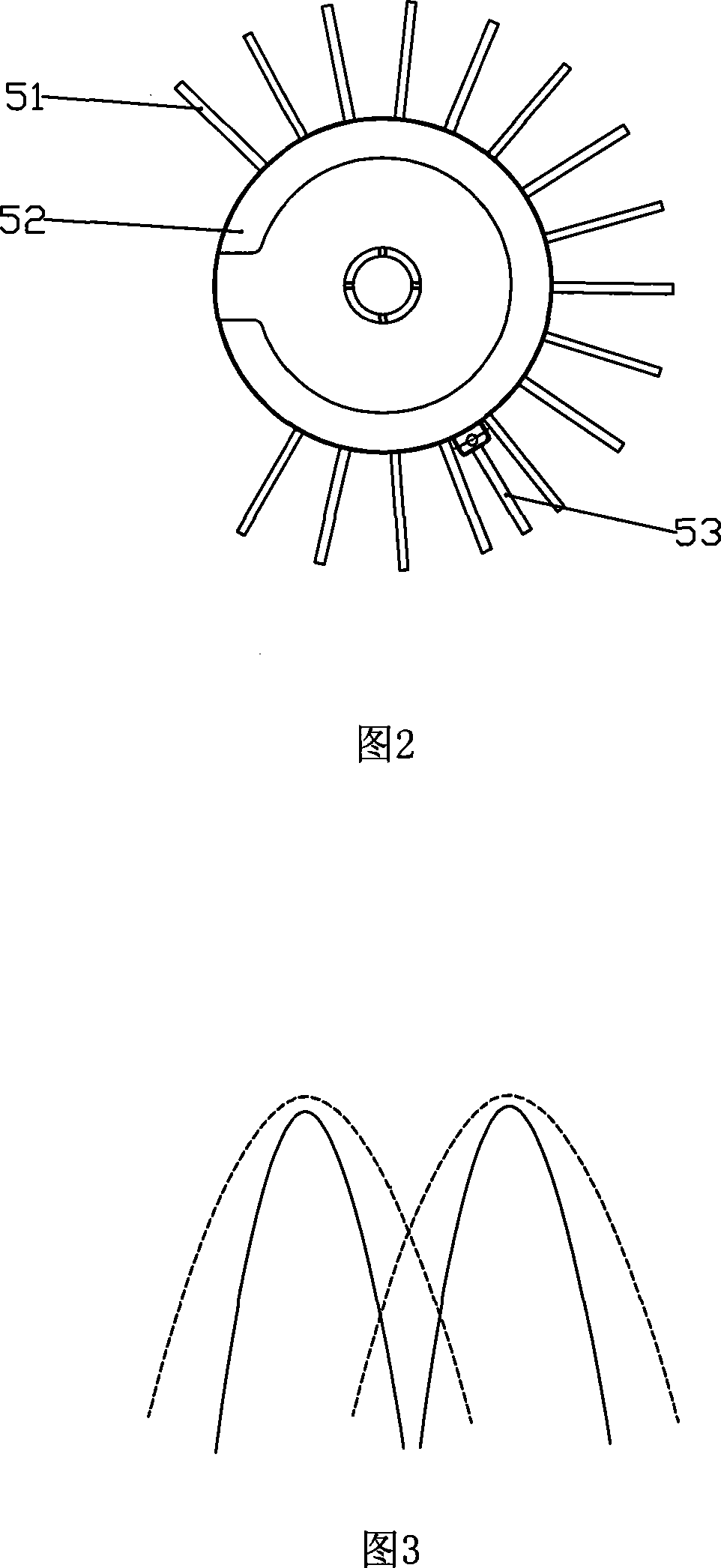

[0040] As shown in Figure 2, the water diffuser is composed of a plurality of radially arranged water diffusers 51 of equal length, which are radially distributed and welded on the same height (or bottom) of the side wall (or bottom) of the round water plate 52, and the whole water diffuser is installed on the Ice machine barrel refrigeration evaporator top position. The included angles between adjacent water pipes 51 are the same except that there is no water pipe p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com