Gas-oil separator

An oil and gas separator, a new type of technology, is applied in the direction of separation method, dispersed particle separation, dispersed particle filtration, etc., and can solve the problems such as unusable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

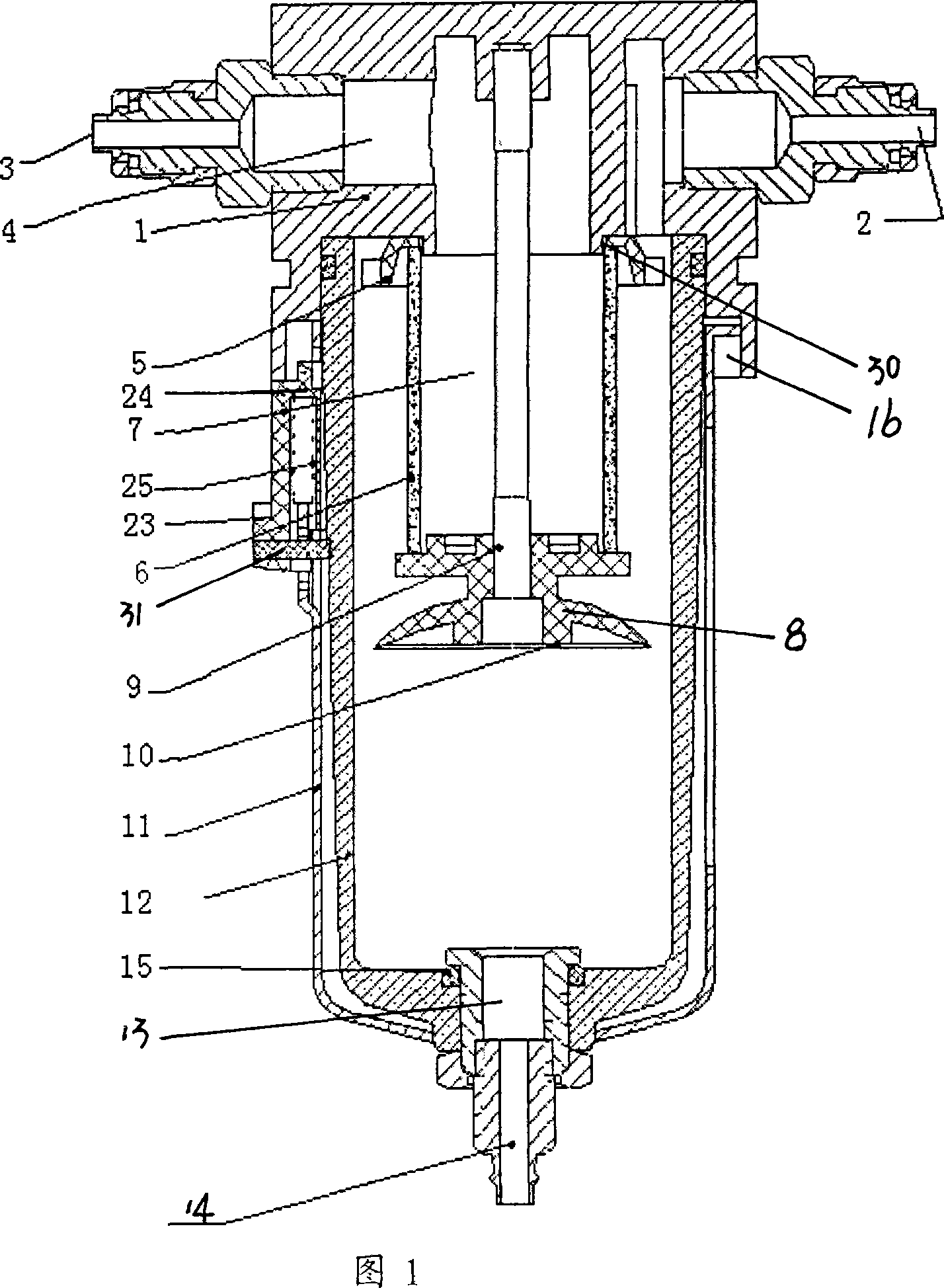

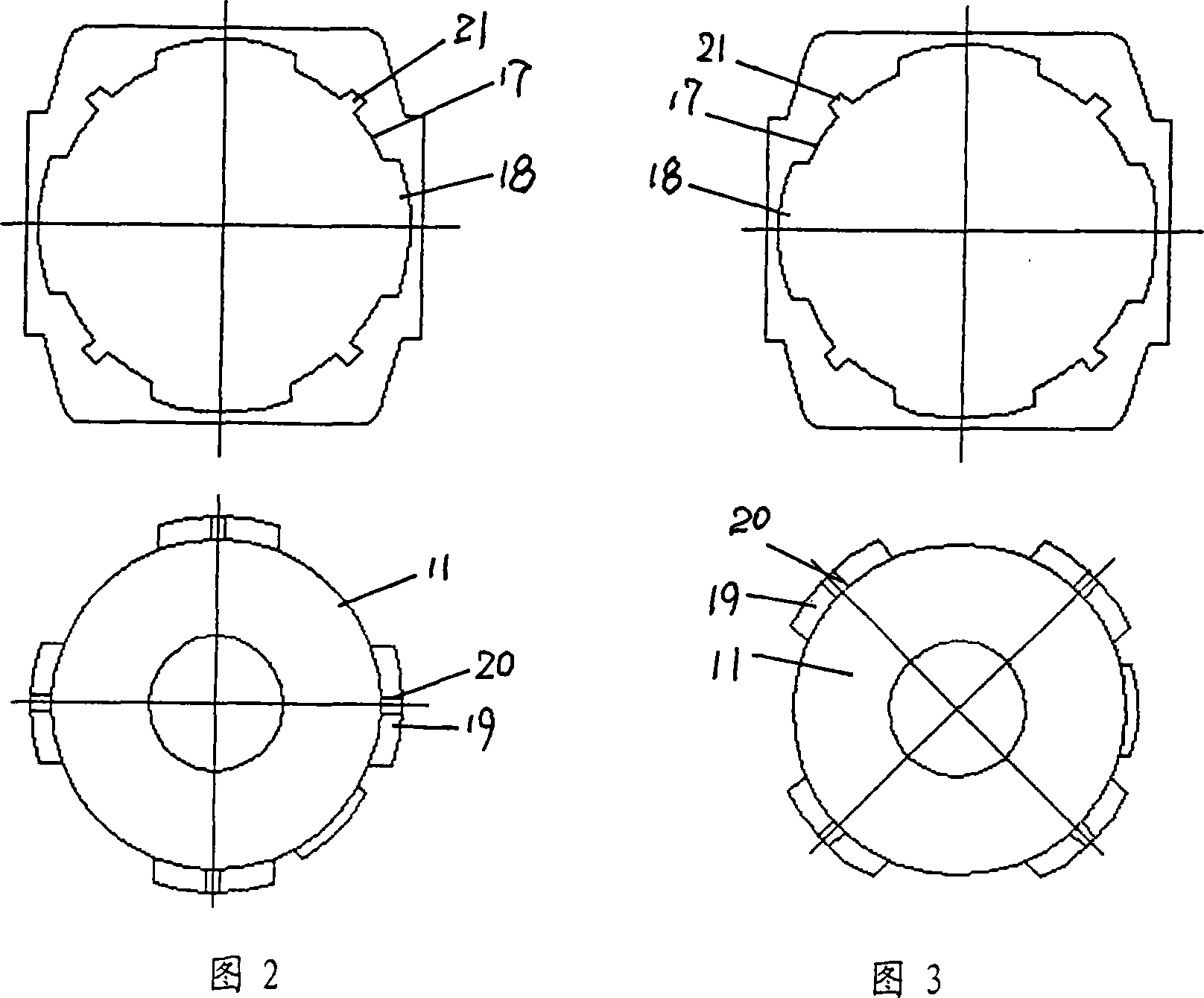

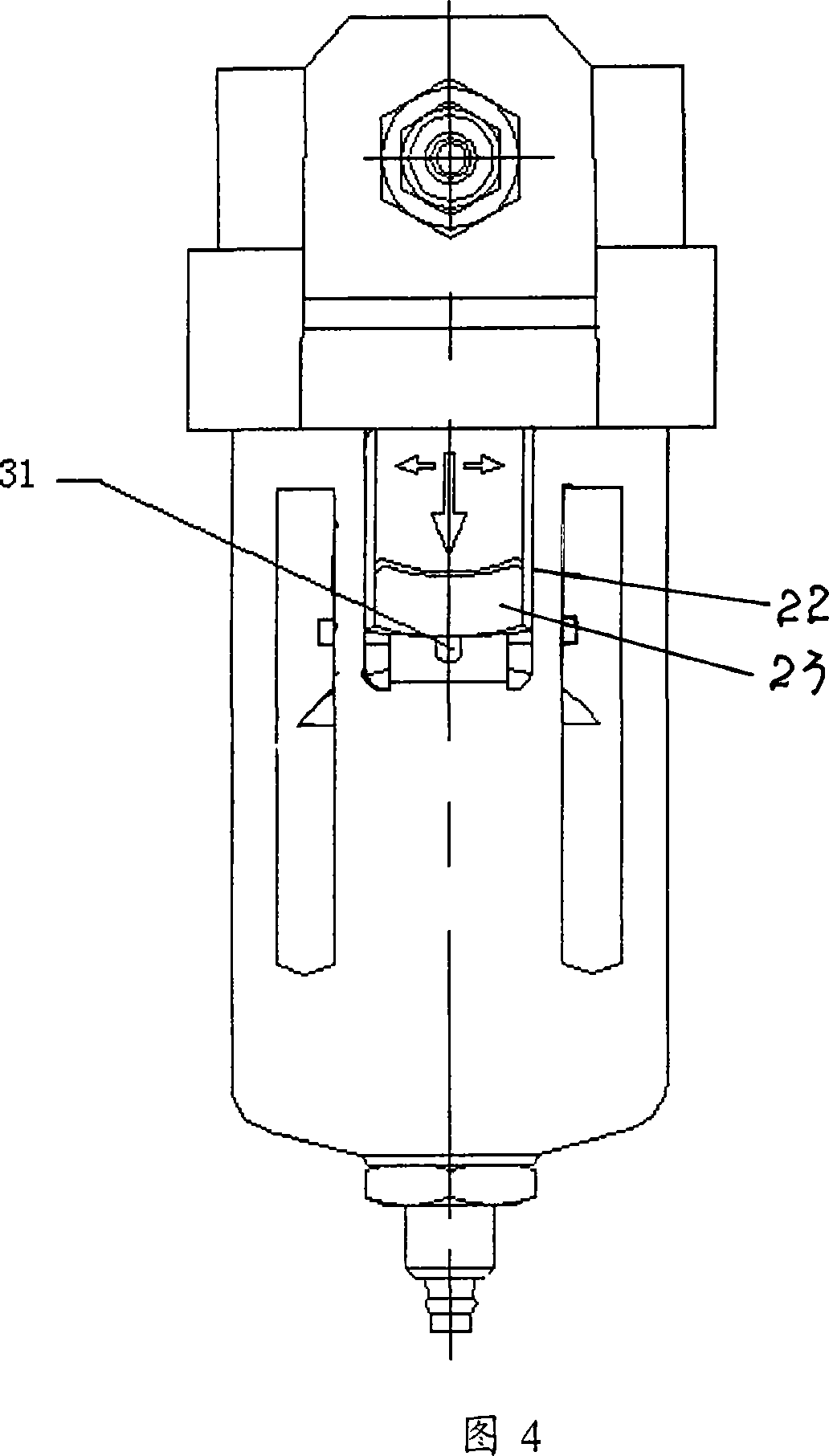

[0011] As shown in FIG. 1 , an air inlet 2 and an air outlet 3 are provided on the upper cover 1 of the oil-gas separator, and the air outlet cavity 4 in the upper cover 1 communicates with the air outlet 3 . A filter element holder 5 is provided on the air outlet cavity wall 30 in the upper cover 1 , and a filter element 6 is arranged on the filter element holder 5 . The filter element 6 is a hollow structure to form a cavity 7 for filtering and separating the gas, and the cavity 7 in the filter element 6 communicates with the gas outlet cavity 4 in the upper cover 1 . The filter element 6 can be cup-shaped, and the filter element mouth "cup mouth" is connected with the filter element holder 5 or the upper cover 1 . It can also be "cylindrical". The filter element 6 of this embodiment adopts a "cylindrical shape". One end opening of the filter element 6 is connected to the filter element holder 5, and the other end opening is connected to the filter element cover 8. The conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com