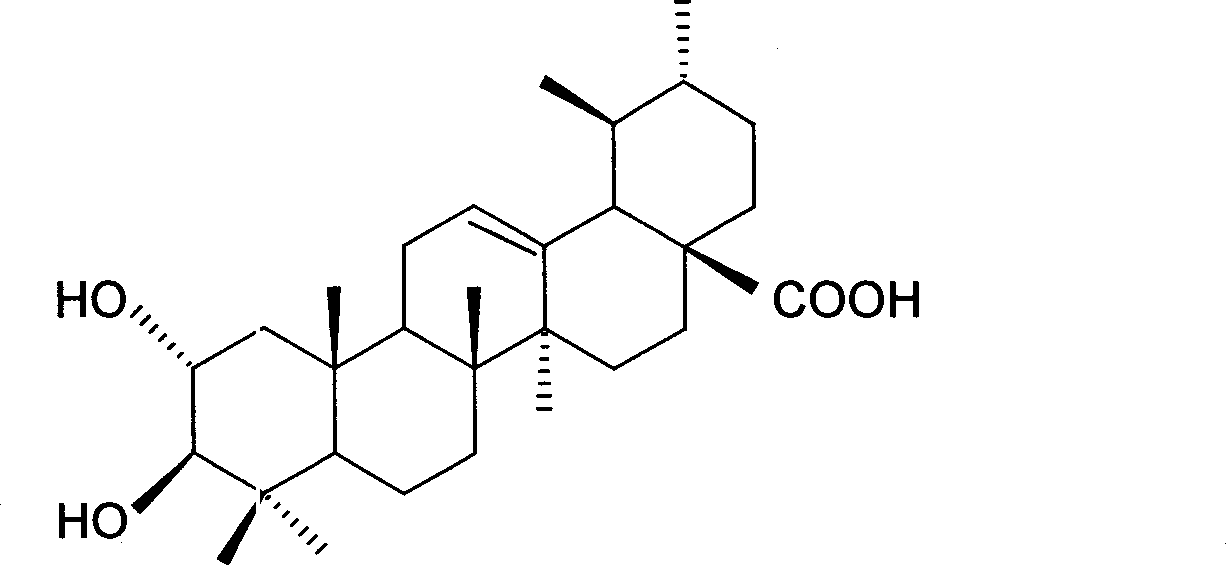

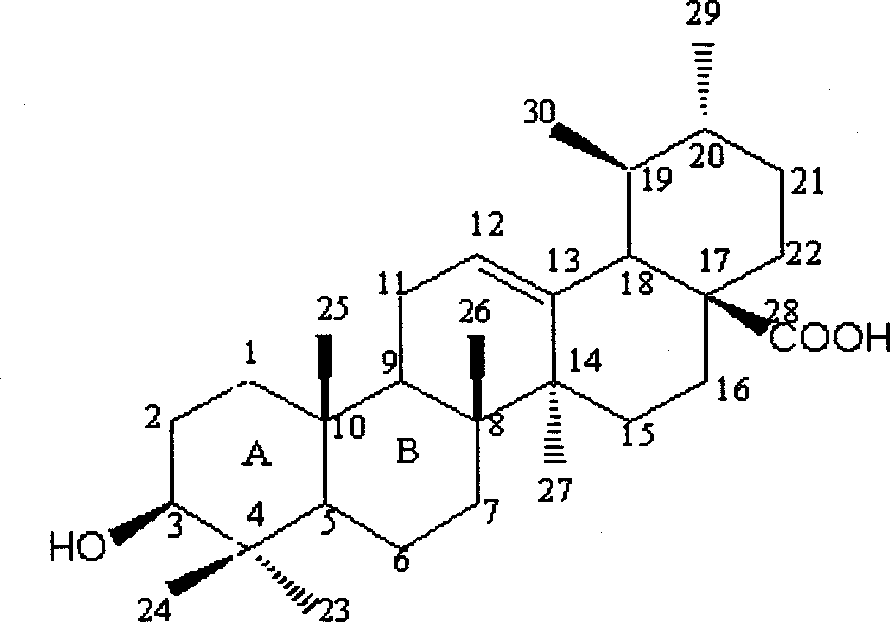

Method for separating and preparing corosolicacid in loquat leaf

A technology of corosolic acid and loquat leaves, applied in the field of separation and preparation of corosolic acid from loquat leaves, achieving the effects of efficient separation, good solubility and strong penetration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Using loquat leaves produced in Putian, Fujian as raw materials, wash fresh loquat leaves with water, dry (air-dried, oven-dried or sun-dried), crush, and sieve through 20-30 meshes to obtain loquat leaf powder, and put 5.2kg of loquat leaf powder into the extraction In the tank, use 95% edible alcohol 15 times the dry weight of loquat leaves (W / W), extract 3 times at 65°C under the condition of pH value 4, each time for 2 hours, combine the extracts, filter; the filtrate is oxidized with hydrogen Adjust the pH value to 9.0 with sodium, let stand and age at 65°C for 3 hours, filter to remove insoluble matter, add 1 kg of activated carbon to decolorize at 65°C for 1 hour, and filter. The filtrate was adjusted to pH 8.0 with dilute hydrochloric acid aqueous solution, the ethanol concentration reached 50% and the total triterpene acid concentration was 0.5 g / L, wherein the corosolic acid concentration reached 0.2 g / L.

[0037] Next, the filtrate is adsorbed to saturation b...

Embodiment 2

[0040] First put 4.6kg loquat leaf powder into the extraction tank, adopt 80% methanol aqueous solution of 10 times of loquat leaf dry weight (W / W), under the condition of pH value 11.0, extract 3 times at 50 ℃, each 1 hour, The extracts were combined and filtered; the filtrate was left to age at 50°C for 1 hour, filtered to remove insoluble matter, and then 0.9 kg of activated carbon was added to decolorize at 50°C for 0.5 hour, and then filtered. Filtrate is under -0.05~-0.09MPa, 50~75 ℃ of conditions, after decompression recovery part methanol solvent, adjust the pH value of loquat leaf total triterpene acid solution to 11.0 with dilute sulfuric acid aqueous solution, methanol concentration reaches 20% and total The concentration of triterpene acid was 4.0g / L, and the concentration of corosolic acid reached 1.5g / L.

[0041] Then, the filtrate is adsorbed to saturation by D101 macroporous adsorption resin for corosolic acid, and the unadsorbed loquat leaf total triterpene ac...

Embodiment 3

[0044] First put 6.3kg of loquat leaf powder into the extraction tank, use absolute ethanol with 5 times the dry weight of loquat leaves (W / W), under the condition of pH value 7, extract under reflux at 80°C for 2 hours, filter; Adjust the pH value to 12.0 with sodium oxide, stand and age at 70°C for 2 hours, filter to remove insoluble matter, add 1.2kg of activated carbon to decolorize at 70°C for 1.5 hours, filter; the filtrate is at -0.05~-0.09MPa, 50~75°C After recovering part of the ethanol solvent under reduced pressure, adjust the pH value to 12.0 with ethanol aqueous solution containing dilute hydrochloric acid, the ethanol concentration reaches 40% and the total triterpene acid concentration is 10.0g / L, wherein the corosolic acid concentration reaches 5.0g / L.

[0045] Next, the filtrate is adsorbed to saturation by HZ816 macroporous adsorption resin for corosolic acid, and the unadsorbed loquat leaf total triterpene acid residue liquid and 2 times the resin amount ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com