Foaming concrete building block automatic production line

An automated production line, foamed concrete technology, applied in chemical instruments and methods, molds, cement mixing devices, etc., to achieve the effects of reducing environmental pollution, strong production capacity, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

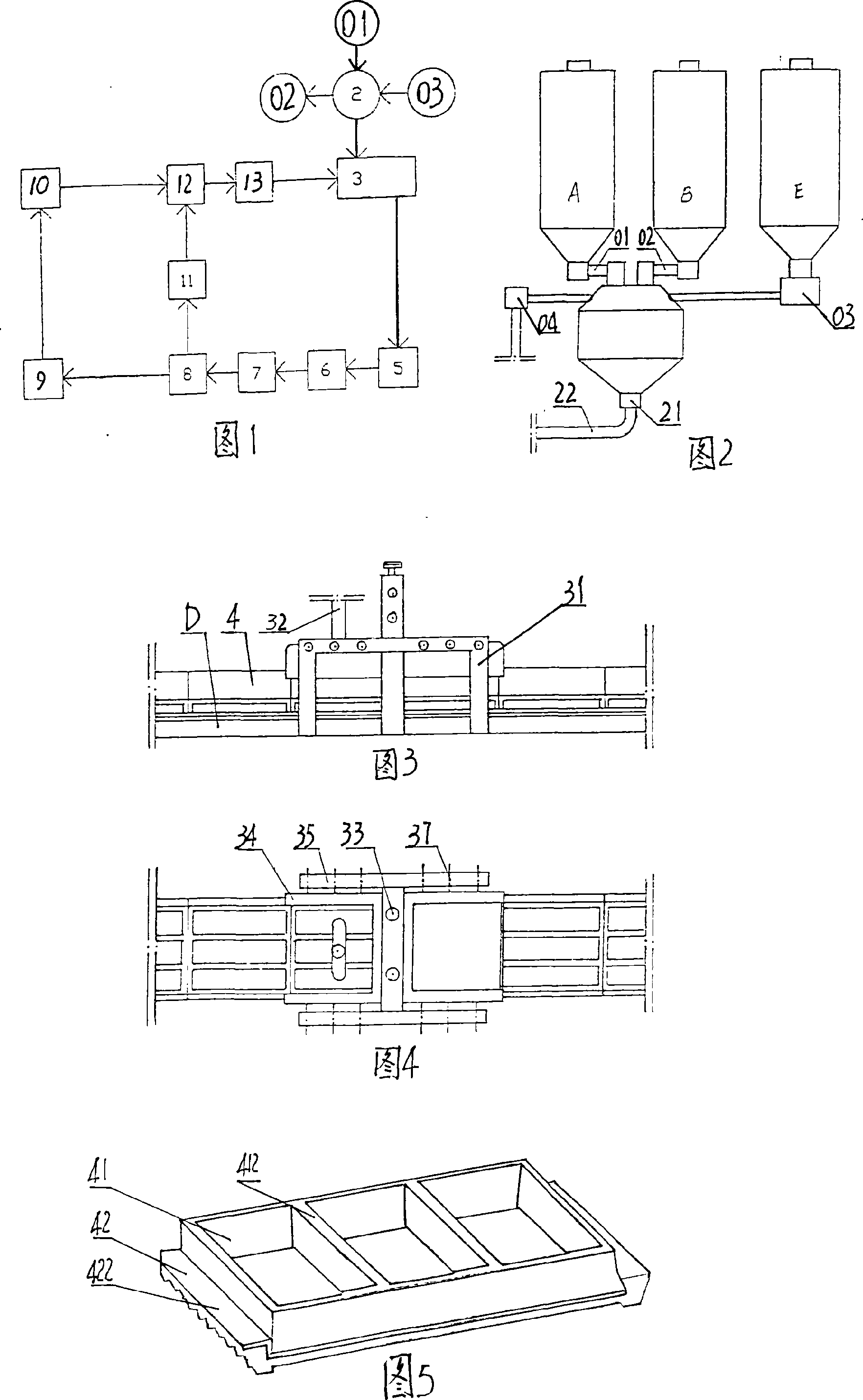

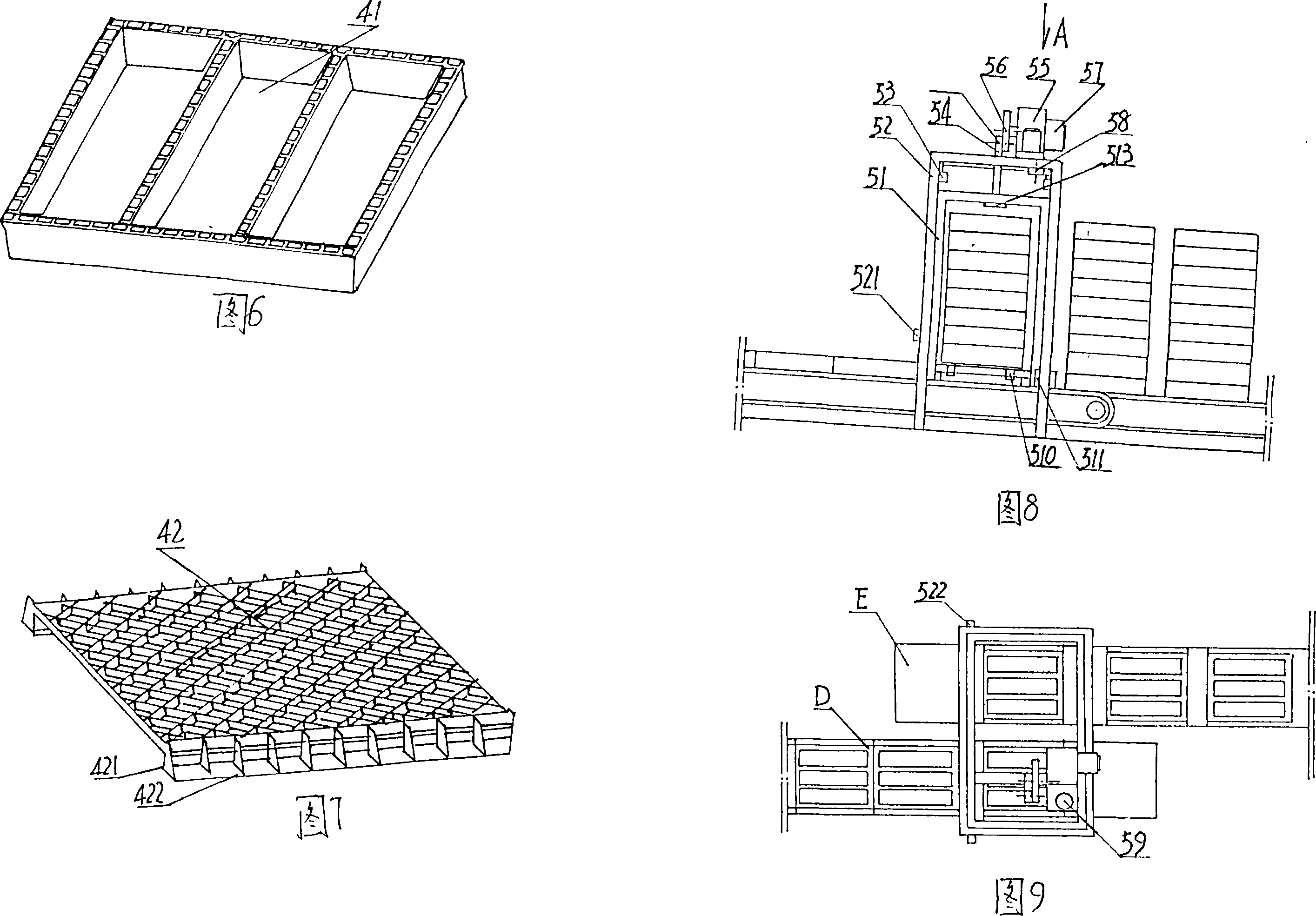

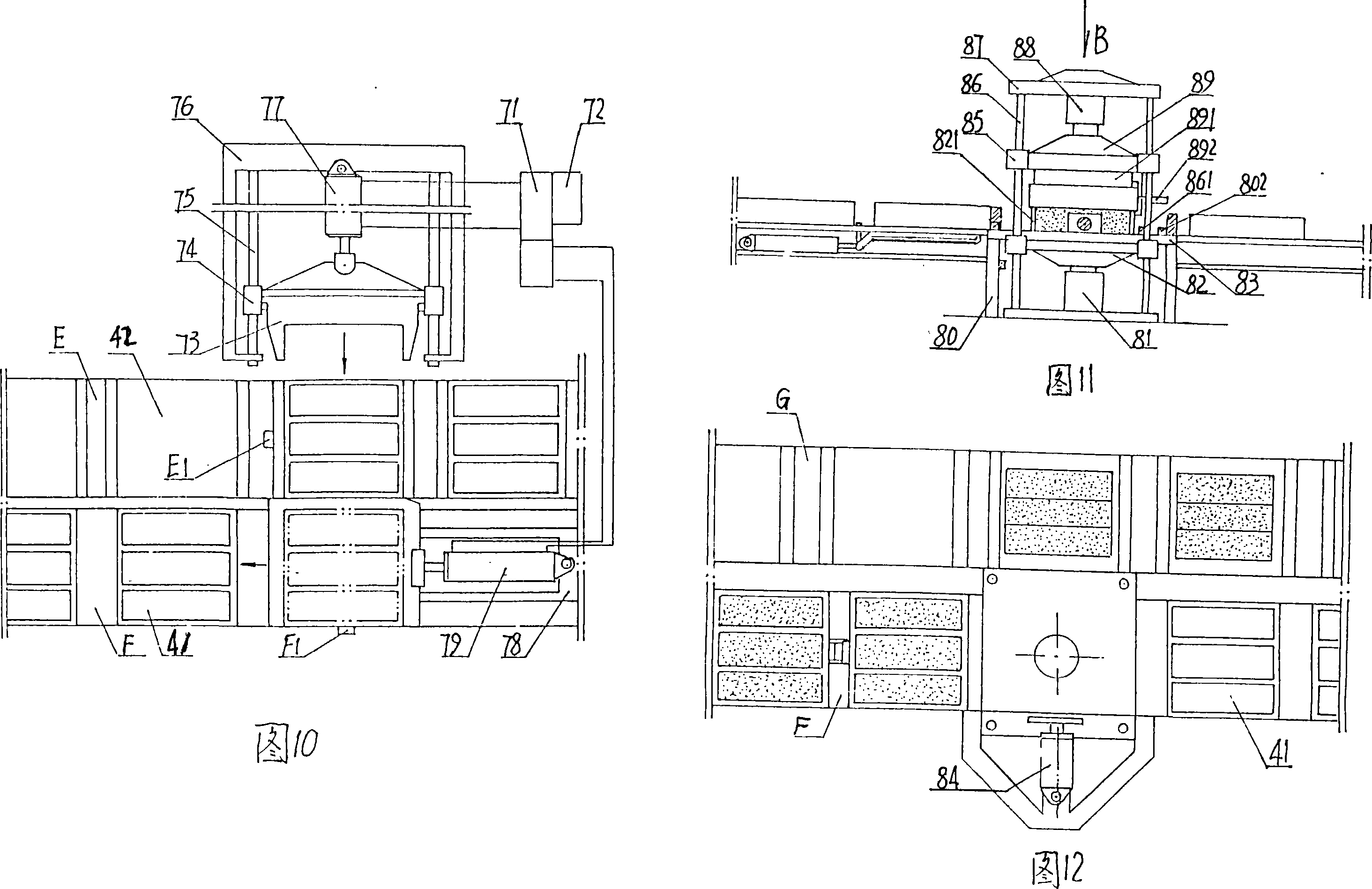

[0023] As shown in Figure 1, the automatic production line of foamed concrete blocks consists of screw conveyors 01 and 02, foaming machine 03, comprehensive mixer 2, pouring and troweling machine 3, palletizing machine 5, decoding machine 6, and bottom pumping machine 7. It is composed of stripping machine 8, off-line code collection machine 9, mold washing machine 11, trigger cleaning 10, mold setting machine 12, liquid spraying machine 13 and central controller.

[0024] As shown in Figure 2, the upper part of the comprehensive mixer 2 is provided with a cement inlet, a fly ash inlet, a blowing agent inlet and a water inlet. The cement and fly ash required for the production of foamed concrete blocks are transported from the silos A and B to the comprehensive mixer 2 according to the set ratio through the screw conveyors 01 and 02 equipped with sensors respectively, and the screw conveyors The flow of the machine is controlled by the central controller. The foaming machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com