Non-fan chip heat radiator

A chip heat dissipation, fanless technology, applied in the direction of cooling/ventilation/heating transformation, instruments, semiconductor devices, etc., can solve the problems of limited life, high heat of cooling chips, crashes, etc., to achieve good vibration resistance, no noise interference, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

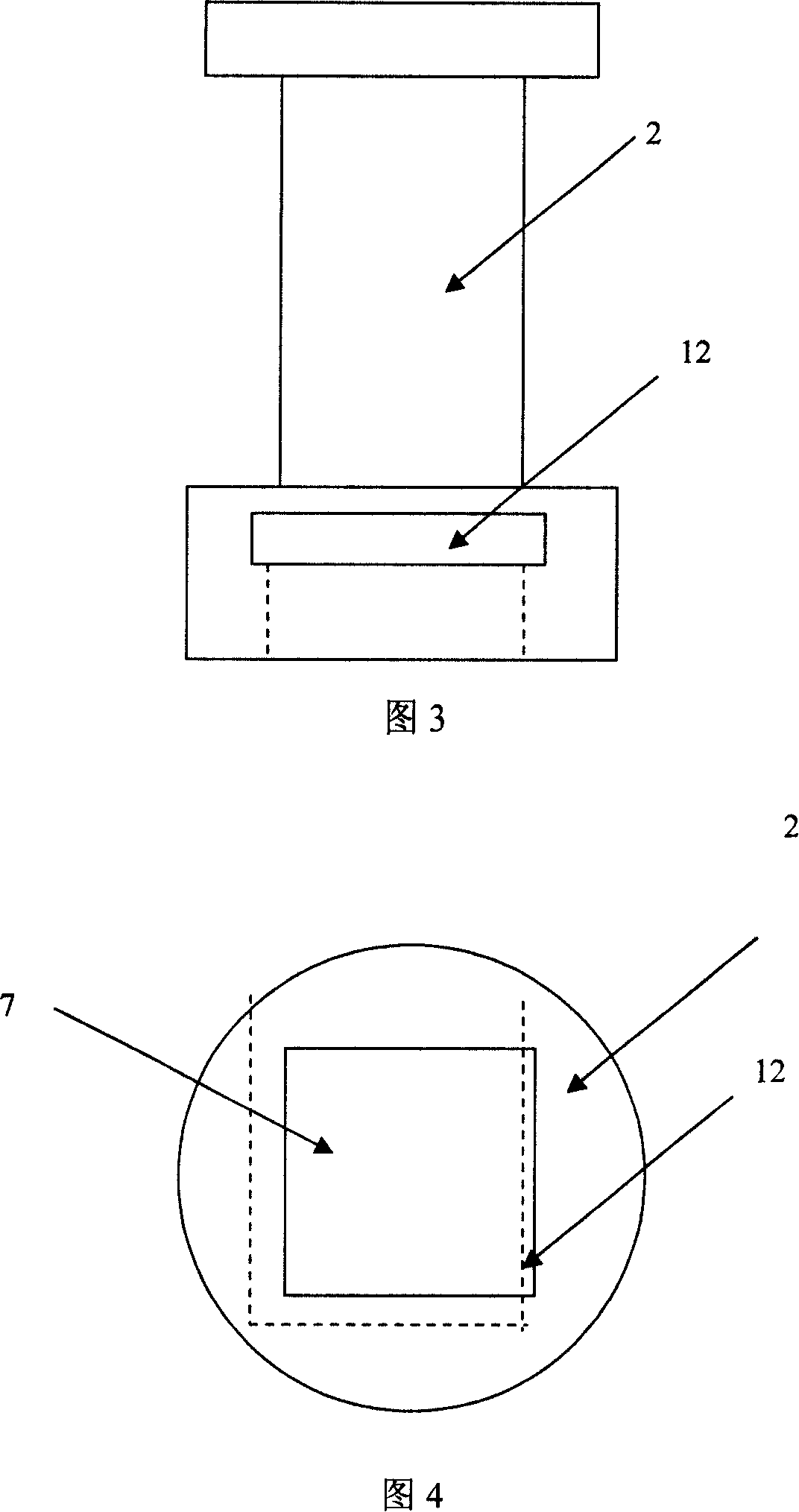

[0012] Below in conjunction with accompanying drawing, take common horizontal computer Pentium P4 main board as example, the present invention is described in further detail.

[0013] Referring to Fig. 1, according to the fanless chip cooling device that the present invention makes, it comprises the cooling chassis 1 of band metal fin 2, heat-conducting rubber 3 and refrigeration chip 8, and cooling chassis 1 adopts the alloy (such as aluminum alloy) with good thermal conductivity Made, the size of the cooling case 1 (not including the fins) is 500mm×500mm×300mm. The metal fins 2 and the cooling case 1 have an integrated structure, with a height of 20mm and a width of 5mm. The interval between the metal fins 2 is 5mm, which is set at equal intervals. For the convenience of installation, the cooling case 1 can be divided into upper and lower parts. The upper and lower parts pass through Screw connection, there is a groove guide rail 4 at the position corresponding to the chip 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com