Aluminum covered steel wire

A technology of aluminum clad steel wire and aluminum cladding, applied in the direction of rod/rod/wire/strip conductor, conductor, electrical components, etc., can solve problems such as failure to meet mechanical performance requirements, large gaps, icing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

[0025] The first embodiment of the present invention is:

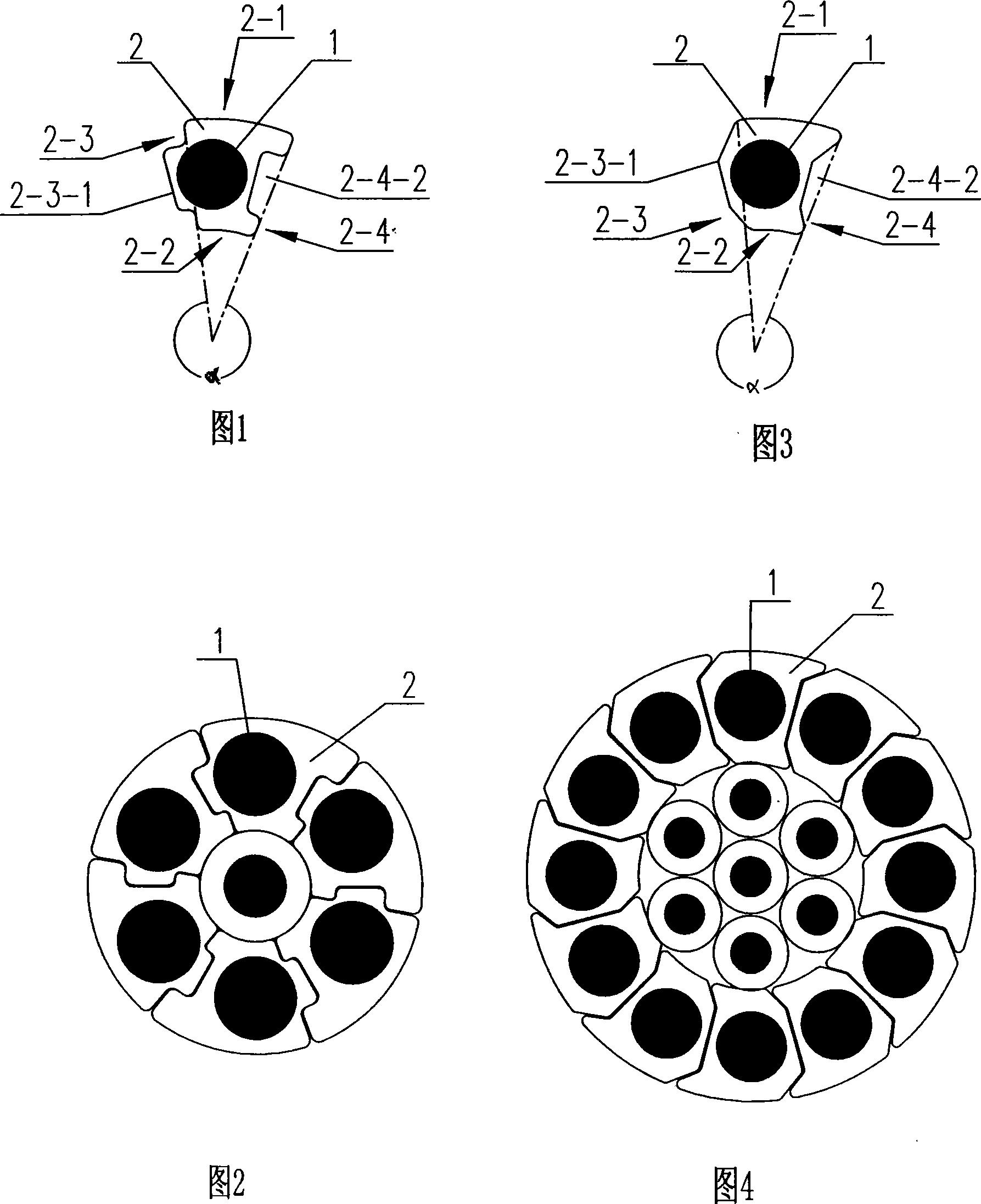

[0026] As shown in Figures 1 and 2, an aluminum-clad steel wire includes a steel core 1 and an aluminum cladding layer 2 covering the periphery of the steel core 1. The outer contour of the section of the aluminum cladding layer 2 has concentric circles. Upper edge 2-1 and lower edge 2-2; the outer contour of the section of the aluminum cladding layer 2 has a left edge 2-3 with a convex edge 2-3-1 and a right edge with a concave edge 2-4-2 2-4; After the center of the concentric circles of the left side line 2-3 and the upper side line 2-1 and the lower side line 2-2 is the center and turned a central angle α, its convex edge 2-3-1 and the right side line 2-4 The concave edge fits 2-4-2.

[0027] As shown in Figures 1 and 2, in order to better ensure the tightness of the wires, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com