Small hydropower water regime operation system

An operation system and small hydropower technology, which is applied in the field of water regime operation and automatic control of small hydropower, can solve the problems of low attention to water head loss, insufficient control precision, and low efficiency of units, so as to improve power quality, enhance safety, and improve The effect of power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

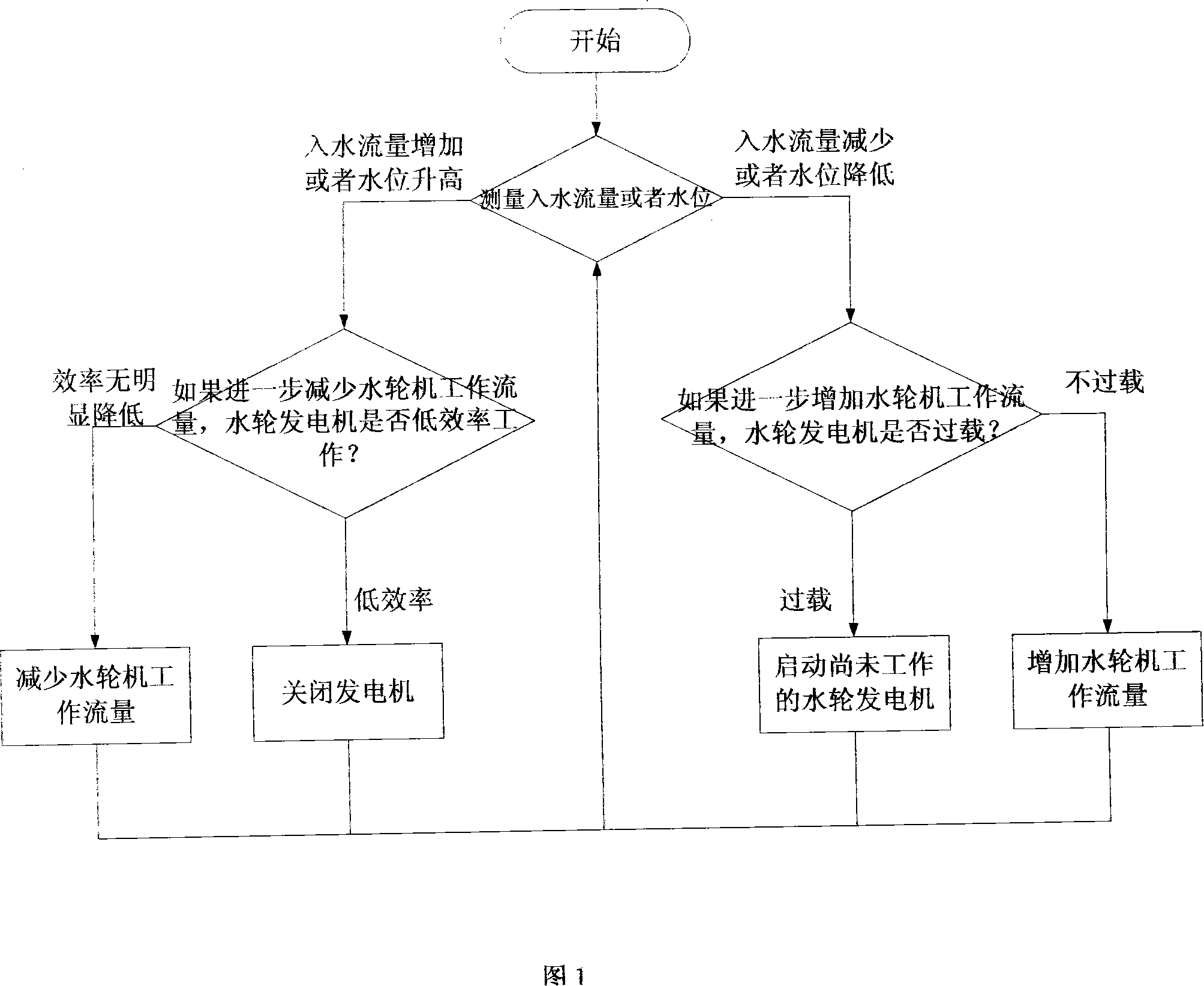

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: In a small hydropower station, there are two generators of 250kw and 320kw respectively, the installed capacity is 570kw in total, the overflow water level of the forebay is 3 meters, and the drop is 90 meters.

[0015] After the summer rainstorm, the system begins to detect that the water level of the forebay has increased. When it is higher than the set value (2.7 meters), the water input power of the forebay is larger at this time. If the system detects that the water level is still rising, it will appropriately increase the working flow of the turbine; when the power of the 320kw generator is greater than the rated power, the system will start another 250kw generator, and adjust the water level according to the detected water level rise. Increase the working flow of the 250kw water turbine to avoid water overflow.

[0016] As time goes by, the runoff water gradually decreases, and the system detects that the water level of the forebay begins to drop. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com