Method for improving absorption speed of water swelling rubber by employing fibre

A water-swellable rubber and water-absorbing speed technology, which is applied in the field of sealing materials, can solve problems such as the decline in rubber mechanical properties and the unsatisfactory water-absorbing speed of polyethylene glycol, and achieve the goal of improving water-absorbing performance, improving the applicable temperature range, and increasing water-absorbing speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

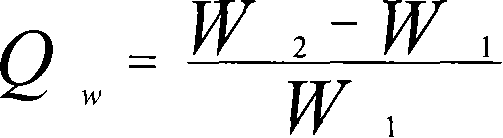

Embodiment 1

[0029] Add cellulose staple fibers (i.e. cellulose fibers with a length of about 1mm cm) with a mass ratio of 10:50:50, octyl acrylate, and neoprene into the container, stir continuously until they are evenly dispersed, pour them out, and heat them at 80°C Vacuum dried to obtain mixture A. (parts by mass, the same below) 50 parts of mixture A, 50 parts of neoprene rubber, 30 parts of acrylic water-absorbing resin, 5 parts of paraffin oil, 1 part of stearic acid, 5 parts of zinc oxide, 4 parts of magnesium oxide, 2 parts of anti-aging Agent D, 1 part of accelerator CZ, and 30 parts of pottery clay were mixed evenly on the double-roller mill, and after standing for 12 hours, the mixed rubber material was pressed and molded, and then directly sent to the vulcanization device for vulcanization (vulcanized The temperature is 200°C, the pressure is 10MPa, and the time is 30min), to obtain a water-swellable rubber that can expand with water in the range of 25°C to 150°C. Take 10 gra...

Embodiment 2

[0031] Add aramid fiber staple fiber (that is, aramid fiber, about 5mm in length), butyl acrylate, and nitrile rubber with a mass ratio of 15:100:30 into the container, stir continuously until the dispersion is uniform, pour it out, and put it at 80°C Vacuum dried to obtain mixture A. Will (mass parts, the same below) 50 parts of mixture A, 50 parts of nitrile rubber, 30 parts of acrylic water-absorbing resin, 5 parts of plasticizer DOP, 1 part of stearic acid, 5 parts of zinc oxide, 2 parts of sulfur, 1 part of Antiaging agent RD, 1 part of antiaging agent MB, 1 part of accelerator DM, 0.5 part of accelerator M, 20 parts of semi-reinforcing carbon black, and 20 parts of white carbon black are mixed evenly on a double-roller mill, and then placed for 12 hours , after the mixed rubber material is pressed and molded, it is directly sent to the vulcanization device for vulcanization (the vulcanization temperature is 150°C, the pressure is 10MPa, and the time is 30min). Water-swe...

Embodiment 3

[0033]Add short cotton fibers (i.e. cotton fibers with a length of about 0.5mm), butyl acrylate and butyl rubber with a mass ratio of 20:100:40 into the container, stir continuously until they are evenly dispersed, pour them out, and vacuum them at 80°C Dry to obtain mixture A. (Mass parts, the same below) 50 parts of mixture A, 50 parts of butyl rubber, 30 parts of acrylic water-absorbing resin, 5 parts of paraffin wax, 1 part of stearic acid, 5 parts of zinc oxide, 2 parts of sulfur, 1 part of anti-aging agent D , 30 parts of carbon black, and 2 parts of accelerator are mixed evenly on the double-roller mill, and after standing for 12 hours, the mixed rubber material is pressed and molded, and then directly sent to the vulcanization device for vulcanization (temperature 150 ° C, The pressure is 10 MPa, the time is 30 minutes), and the water-swellable rubber that can expand with water in the range of 25°C to 150°C is obtained. Take 10 grams of the water-swellable rubber samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com