Organic waste water processing method

A technology for organic wastewater treatment and organic wastewater, which is applied in biological water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of unsatisfactory effluent comprehensive indicators and large differences in optimal conditions. and other problems, to achieve the effect of removing organic pollutants, phosphorus and nitrogen removal, high-efficiency chromaticity, and chromaticity removal rate improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Wastewater treatment with a daily treatment capacity of 1,000 tons of organic wastewater.

[0061] Using the existing anaerobic-anoxic-aerobic (A2O) nitrogen and phosphorus removal method, the hydraulic retention time in the anaerobic pool, anoxic pool, and aerobic pool is 1 hour, 4 hours, and 4 hours respectively. The volume ratio of gas to water in the oxygen tank is 6:1, the sludge concentration in the aerobic tank is 4.5g / l, and the sludge load is 0.160kgBOD 5 / kg / MLSS / d, the amount of nitrifying liquid flowing back from the aerobic tank to the anoxic tank is 150%, and the amount of sludge flowing back from the secondary settling tank to the anaerobic tank is 20%. The effluent after treatment is required to be higher than the pollutant discharge standard for urban wastewater treatment plants Class I B (GB18918-2002). The design and operation results are shown in Table 1.

[0062] In the present invention, COD cr Indicates the chemical oxygen demand, which is deter...

Embodiment 2

[0075] Wastewater treatment with a daily treatment capacity of 1,000 tons of organic wastewater.

[0076] Use the organic wastewater listed in Table 1 for treatment.

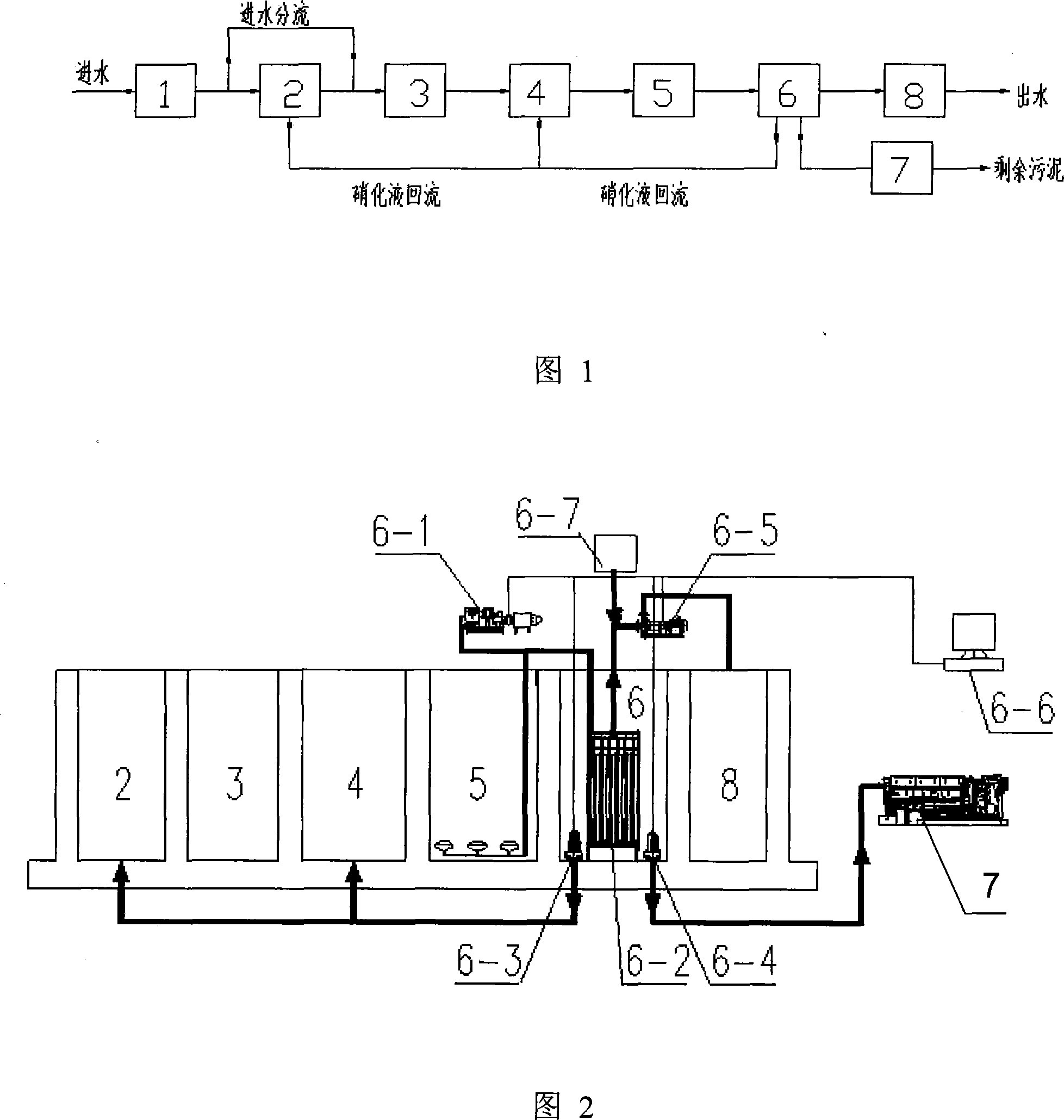

[0077] The organic wastewater first enters the pretreatment system 1 generally composed of coarse screens, lifting pump rooms, fine screens, grit chambers and ultra-fine screens to remove large particles of impurities present in the wastewater; then 10% pretreatment by volume The waste water enters the first anoxic pond 2, while the remaining pretreated waste water enters the anaerobic pond 3;

[0078] In the first anoxic tank 2, the pretreated waste water was mixed with 50% by volume of the backflow nitrification liquid from the membrane bioreactor 6 for 1.0 hour under the condition of anoxic, and a preliminary denitrification reaction was carried out to obtain The reaction solution then enters the anaerobic tank 3, and is mixed with the remaining part of the pretreated wastewater under anaerobic conditions fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com