A concrete protective film laying device

A laying device and protective film technology, which is applied in roads, building materials processing, construction, etc., can solve the problems of poor laying quality and slow laying of concrete protective film, and achieve high laying efficiency, improved laying quality, and strong clamping force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

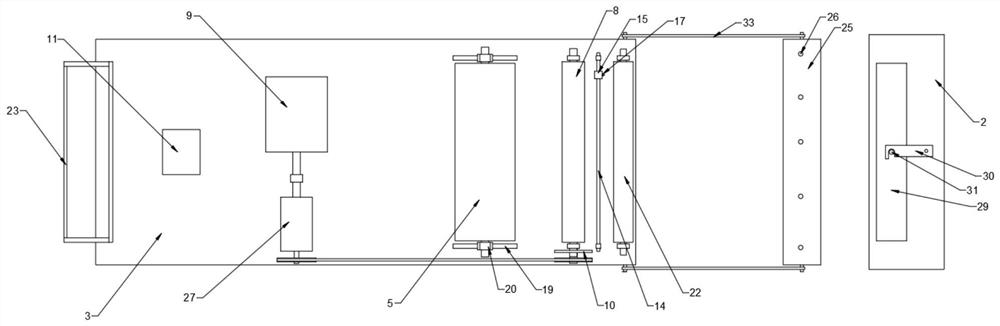

[0033] This embodiment, as the basic embodiment of the present invention, discloses a concrete protective film laying device, the specific structure is as follows figure 1 and Figure 4 As shown, it includes a laying trolley 1 and a fixed pile 2. The laying trolley 1 includes a frame 3, and the two sides of the bottom of the frame 3 are rotated to be provided with mutually matched rollers 4, and the rollers 4 are connected by rubber crawlers 24; The front section of the frame 3 is fixedly provided with a cart handrail 23, and the middle part of the frame 3 is fixedly provided with a controller 11 and a servo motor 9 electrically connected to each other. The rotating shaft 6 on which the film roll 5 is placed; the tail end of the frame 3 is also rotated to be provided with an active clamping discharge roller 7 and a driven clamping discharge roller 8, and the active clamping discharge roller 7 and the driven The clamping and discharging rollers 8 are connected through a transm...

Embodiment approach 2

[0036] This embodiment, as a preferred embodiment of the present invention, discloses a concrete protective film laying device, the specific structure is as follows Figure 2 to Figure 5 As shown, it includes a laying trolley 1 and a fixed pile 2. The laying trolley 1 includes a frame 3. Two U-shaped support frames 19 that cooperate with each other are fixedly arranged on both sides of the frame 3 tail. A rotating shaft 6 is provided, and the middle part of the rotating shaft 6 is evenly provided with a plurality of support frames 21 adapted to the packaging tube of the film roll 5, and the two ends of the rotating shaft 6 are provided with rolling bearings 20 adapted to the U-shaped support frame 19, and are installed through the U-shaped The open end support of support frame 19 erects rotating shaft 6; At the same time, the active clamping and discharging roller 7 and the driven clamping and discharging roller 8 that cooperate with each other are also rotated at the rear of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com