Five-freedom five-shaft parallel virtual-shaft machine tool

A virtual axis machine tool, a technology of degrees of freedom, applied in the direction of metal processing mechanical parts, large fixed members, metal processing equipment, etc., can solve the problem of undiscovered five-degree-of-freedom five-axis parallel mechanism, waste of drive and transmission device, increased control and manufacturing Difficulty and other problems, to achieve the effect of good processing and assembly technology, simple structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

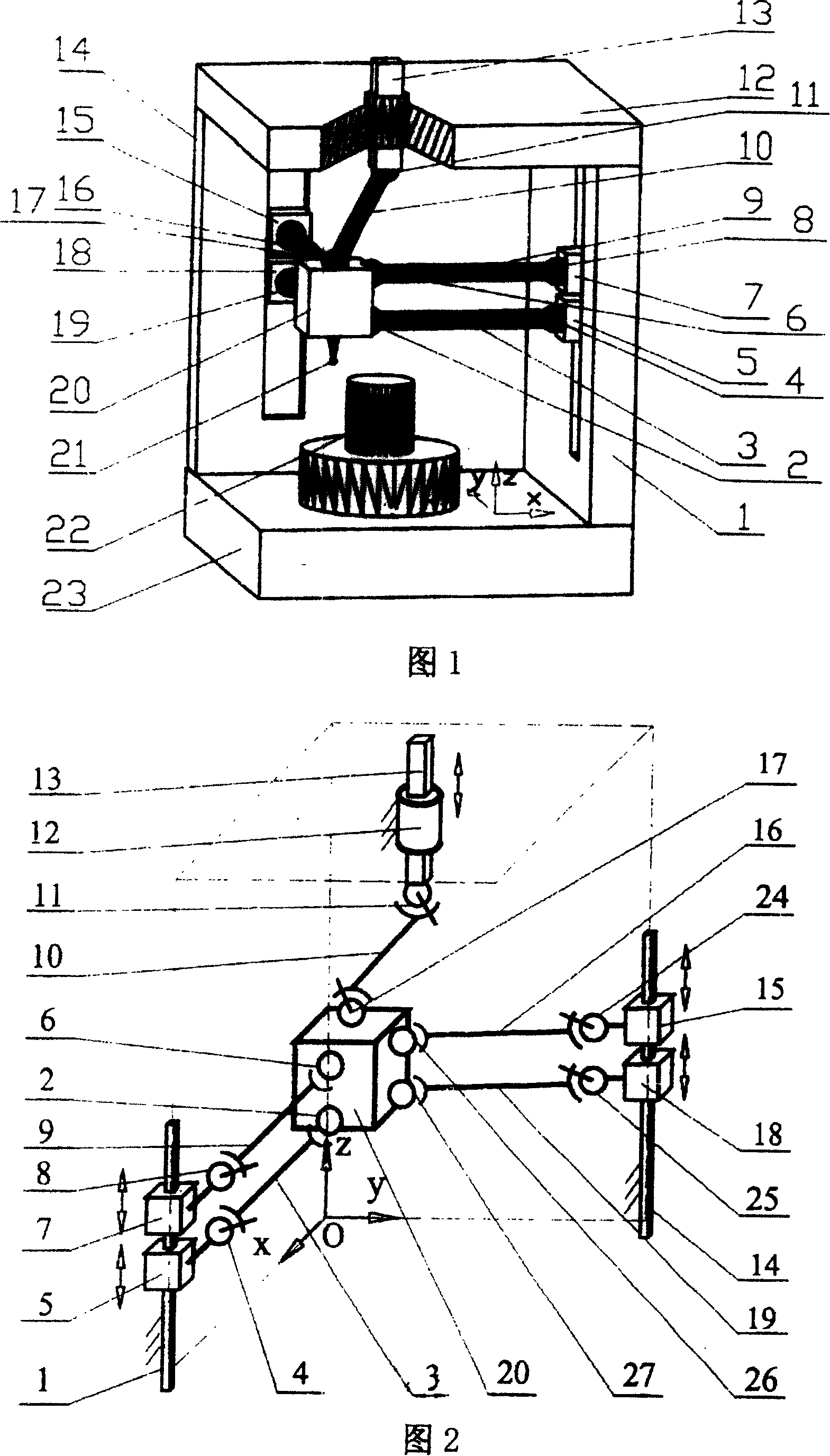

[0033] Embodiment 1: FGSVPMT-1 five-degree-of-freedom five-axis parallel virtual axis machine tool

[0034] The structure of the FG5VPMT-1 five-degree-of-freedom five-axis parallel virtual axis machine tool is shown in Figure 1 and Figure 2. The motion table (20) passes through five connecting rods (3), (9), (10), (16), ( 19) It is connected with the fixed platform composed of three mutually perpendicular side panels (1), top panel (12) and back panel (14). on mutually perpendicular planes. Two double-supported fixed-length connecting rods (3) and (9), (16) and (19) are respectively connected to two vertical planes of the motion platform through spherical joints (2) and (6), (26) and (27) , two double-supported fixed-length connecting rods (3) and (9), (16) and (19) are connected to the side panel of the fixed table ( 1), the sliders (5) and (7), (15) and (18) on the back panel (14) are connected, the sliders (5) and (7) are installed on the slideway of the side panel (1), a...

Embodiment 2

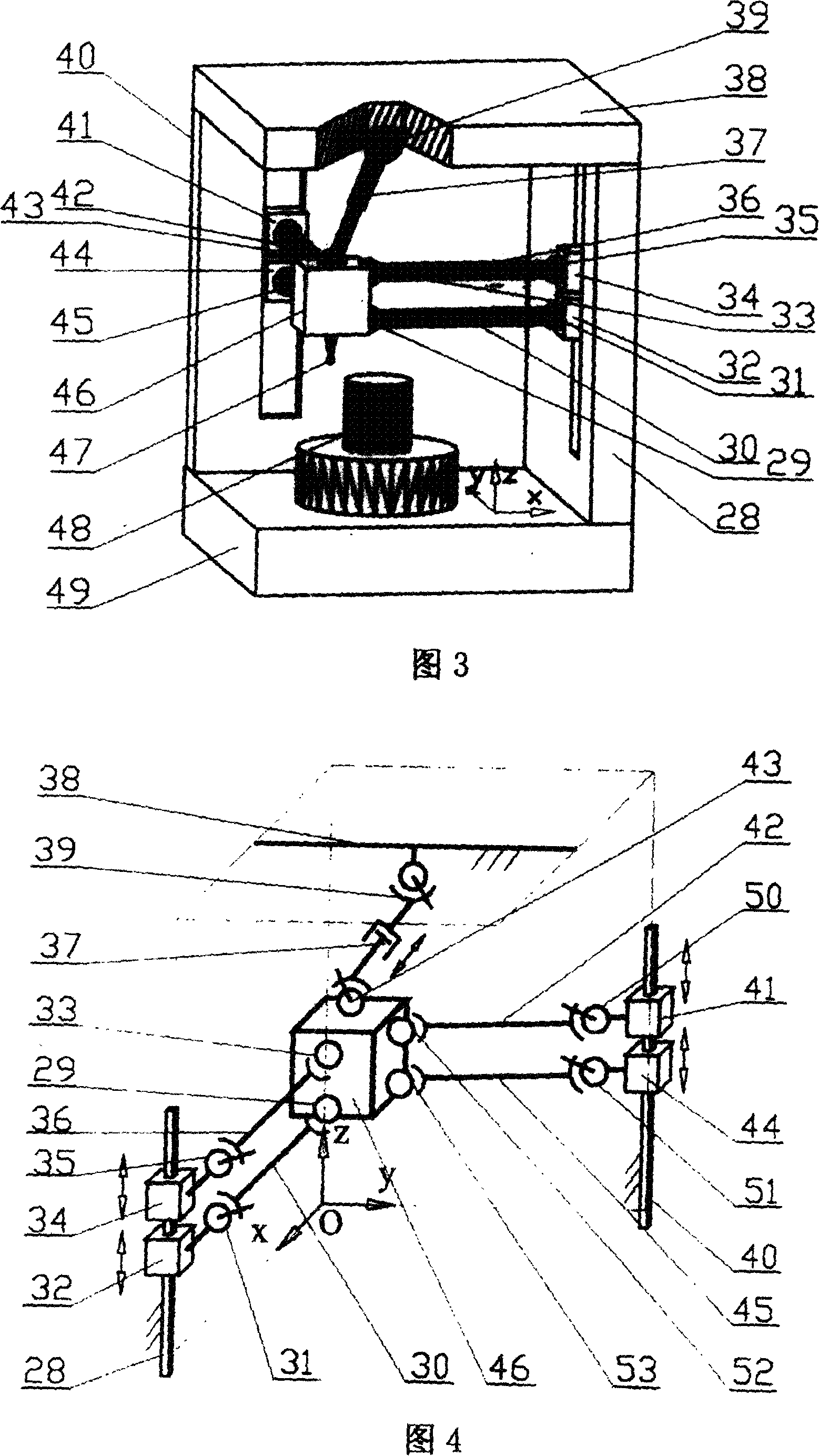

[0036] Embodiment 2-FG5VPMT-2 five-degree-of-freedom five-axis parallel virtual axis machine tool

[0037]The structure of the FG5VPMT-2 five-degree-of-freedom five-axis parallel virtual axis machine tool is shown in Figure 3 and Figure 4. The motion table (46) passes through five connecting rods (30), (36), (37), (42), ( 45) It is connected with the fixed platform composed of three mutually perpendicular side panels (28), top panel (38), and back panel (40), and the kinematic pairs connected with the kinematic platform by five connecting rods are distributed on the three sides of the kinematic platform. on mutually perpendicular planes. Two double-supported fixed-length connecting rods (30) and (36), (42) and (45) are respectively connected to the two vertical planes of the motion platform through spherical joints (29) and (33), (52) and (53) , two double-supported fixed-length connecting rods (30) and (36), (42) and (45) are connected to the fixed table side panel ( 28), t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com