Catalyzer for producing biological ethane and shaping method thereof

A molding method and catalyst technology, applied in the chemical industry, can solve problems such as unreported, and achieve the effects of simple components, improved strength and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

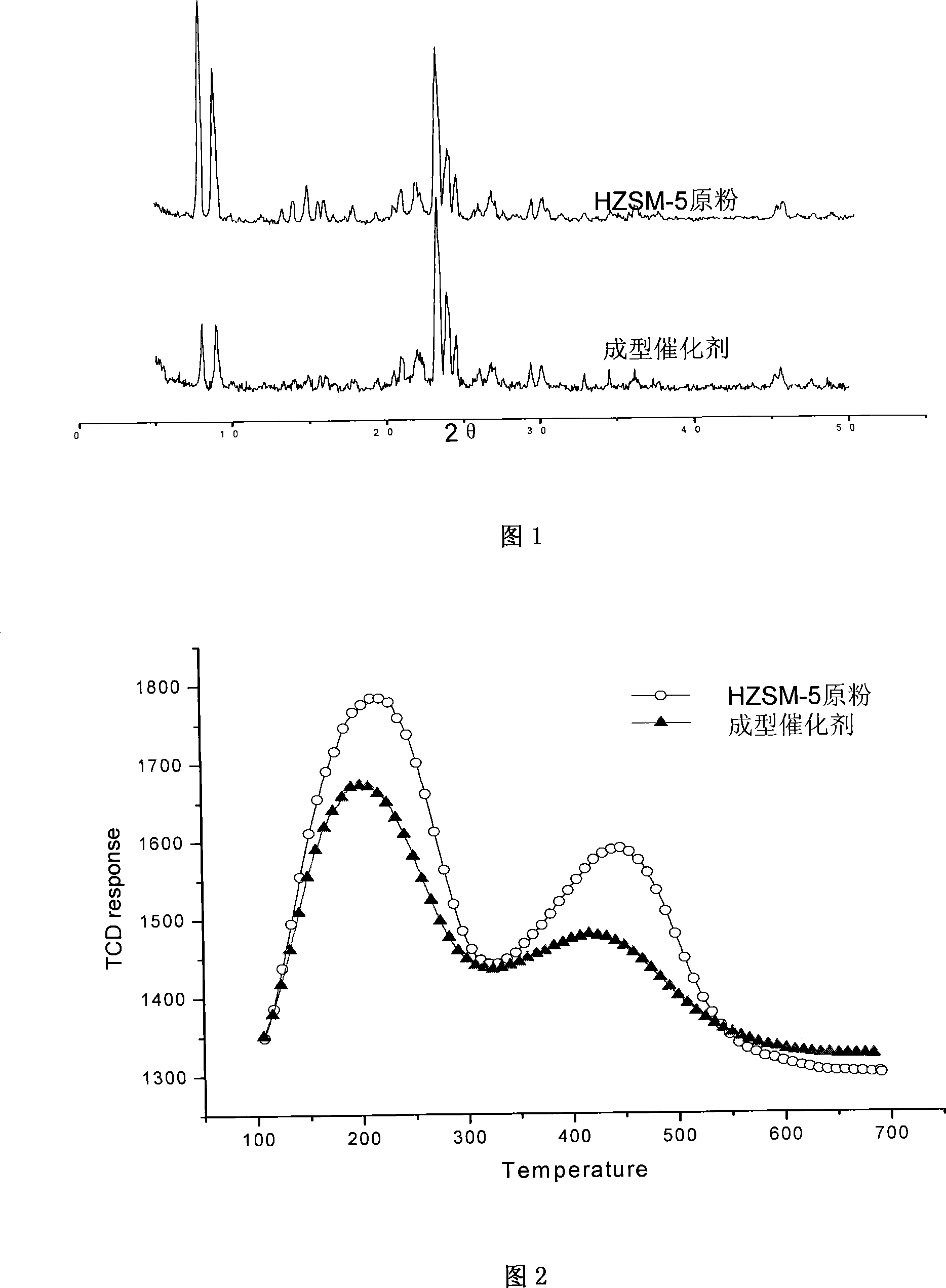

Embodiment 1

[0028] Mix and knead 30g of HZSM-5 molecular sieve raw powder with a molar silicon-aluminum ratio of 25:1, 1g sodium carboxymethylcellulose, 12g phosphoric acid, and 2g water, knead them, form at 40°C for 1 hour, extrude and form them, and dry at 60°C for 15 hours , Calcined at 800°C for 6h, and then washed with water at 100°C for 30 days to obtain the shaped catalyst.

[0029] The catalyst is at a temperature of 220°C, an ethanol concentration of 50wt%, and a mass space velocity of 3.0h -1 The catalytic dehydration reaction was carried out under the reaction conditions.

Embodiment 2

[0031] Mix and knead 30g of HZSM-5 molecular sieve raw powder with a molar silicon-aluminum ratio of 50:1, 25g of silica sol, 0.9g of hydroxypropyl methylcellulose, 1g of phosphoric acid, and 7g of water, knead them, and extrude after forming at 30°C for 24 hours Shaped, dried at 100°C for 2 hours, and calcined at 550°C for 4 hours to obtain the shaped catalyst.

[0032] The catalyst is at a temperature of 250°C, an ethanol concentration of 50wt%, and a mass space velocity of 3.0h -1 The catalytic dehydration reaction was carried out under the reaction conditions.

Embodiment 3

[0034] Mix and knead 40g of HZSM-5 molecular sieve raw powder with a molar silicon-aluminum ratio of 100:1, 73g of silica sol, 12g of sodium carboxymethylcellulose, 2.4g of disodium hydrogen phosphate, and 48g of water, and knead them at 20°C for 48 hours. Extruded, dried at 120°C for 1 hour, and calcined at 650°C for 2 hours to obtain the shaped catalyst.

[0035] The catalyst is at a temperature of 280°C, an ethanol concentration of 50wt%, and a mass space velocity of 3.0h -1 The catalytic dehydration reaction was carried out under the reaction conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com