Method for correcting water level of steam drum based on temperature and pressure

A steam drum water level and pressure technology, which is applied to the pressure to correct the steam drum water level. Based on the temperature field, it can solve the problems of steam drum water shortage and full water, so as to improve dynamic quality, reduce overshoot phenomenon, and ensure normal and stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

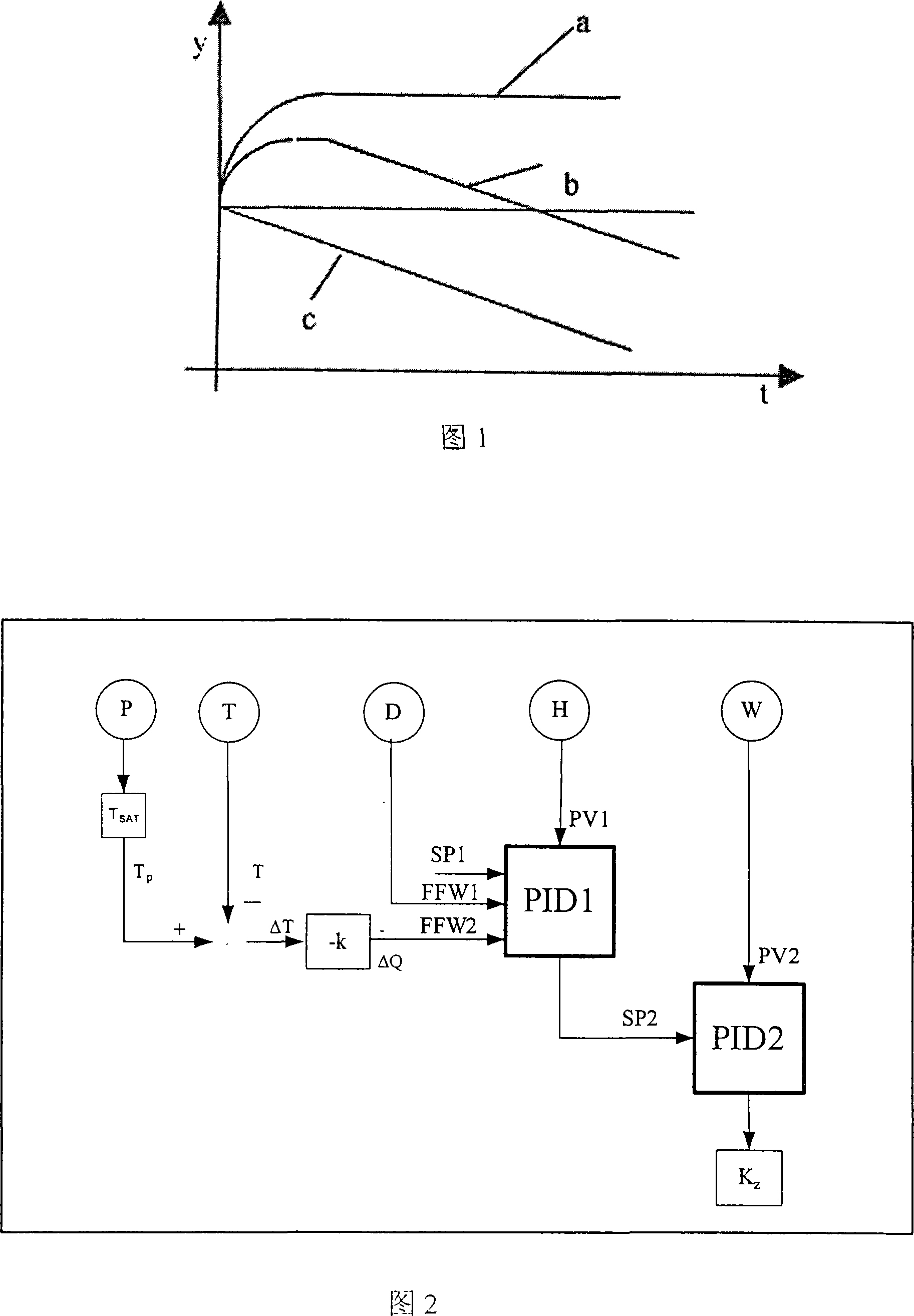

[0011] Referring to Figure 1, it shows the change of water level when the steam is disturbed. When the feed water remains unchanged, the load increases, resulting in an increase of steam flow. If the influence of other factors is not considered, the water level of the drum will drop linearly because the steam flow is greater than the feed water flow. As shown in the curve c of Figure 1; at the beginning of the increase in steam volume, the water level temporarily rises first due to the increase in the volume of the bubbles in the water. Since the volume of the bubbles can only increase to the pressure level of the drum, this increase is limited. After a period of time, the pressure of the steam drum will reach a stable level, and the water level will no longer rise. For example, curve a and curve b are the combined effect of the two, that is, the actual effect of the water level change of the steam drum.

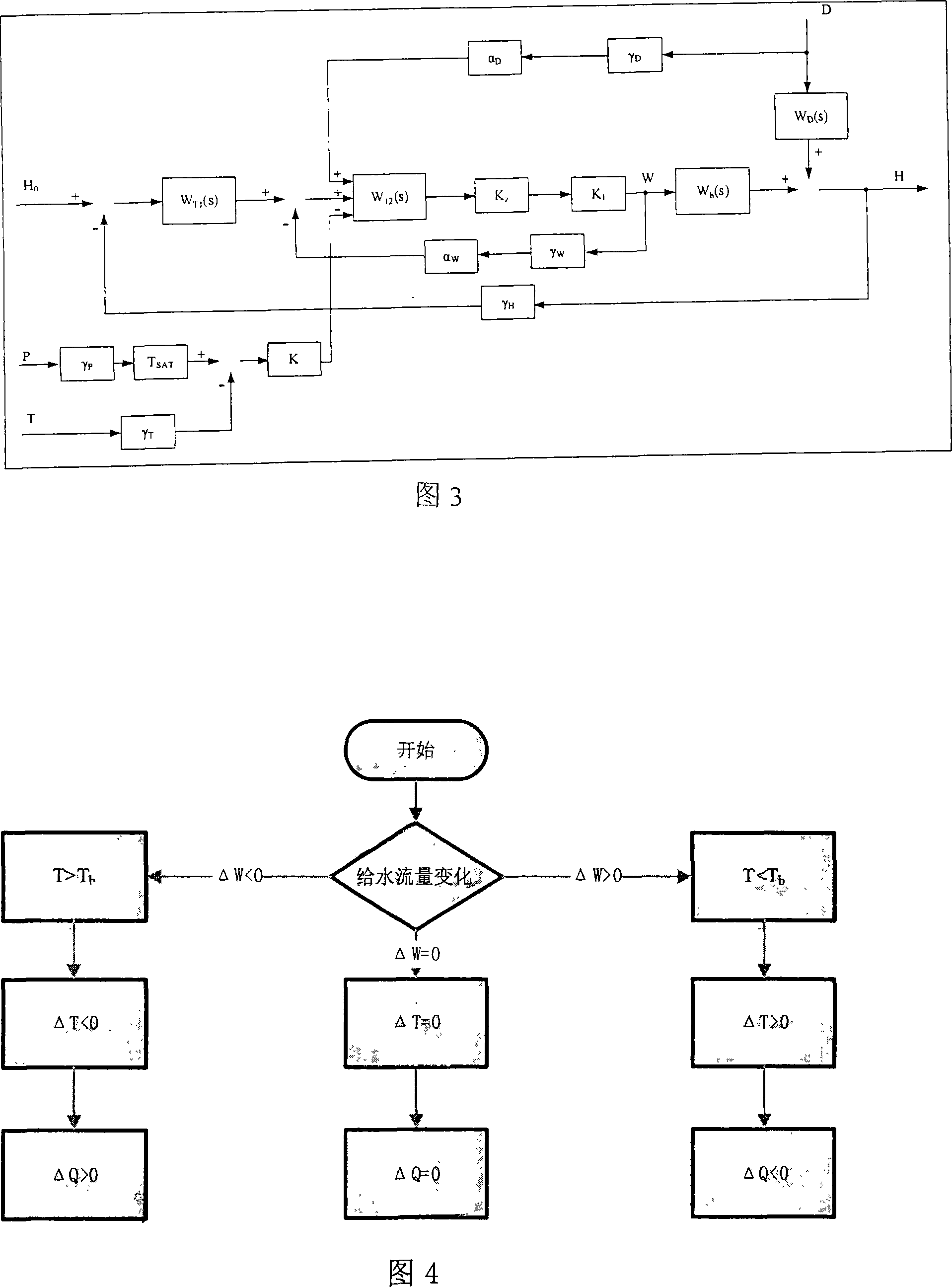

[0012] Referring to Figure 2, it shows the corrected drum water level co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com